In modern manufacturing, precision, consistency, and efficiency are more important than ever, and CNC grinding plays a vital role in meeting these demands. By combining traditional grinding techniques with advanced computer numerical control (CNC) technology, manufacturers can produce highly accurate components for even the most demanding applications.

What is CNC Grinding?

CNC grinding is a high-precision manufacturing process that uses a grinding wheel, an abrasive cutting tool, to remove material from a workpiece, under the automated guidance of a computer-controlled system. This process is used to achieve extremely tight tolerances, superior surface finishes, and complex part geometries that are difficult or impossible to produce with conventional machining.

Unlike conventional grinding methods, CNC systems automate every aspect of the operation – from tool movements to speed adjustments – ensuring consistent results, tighter tolerances, and better surface finishes across both low and high production volumes.

How CNC Grinding Works?

CNC grinding operates through a fully automated system that precisely controls the movement and behavior of a grinding wheel to remove material from a workpiece. The grinding process is governed by a CNC program—typically written in G-code—that defines the tool path, speed, and process parameters. The core control elements include:

- Tool Path and Positioning (X, Y, Z axes, and often rotational axes)

The CNC system controls the linear and rotational movements of the grinding tool and workpiece along multiple axes. This ensures accurate positioning and repeatable grinding paths, which are essential for complex geometries and tight tolerances.

- Grinding Speed and Feed Rate

The grinding speed (relative velocity between wheel and workpiece) and feed rate (rate of material advancement) are adjusted based on material type and surface finish requirements. Optimizing these parameters ensures efficient material removal while minimizing thermal damage and tool wear.

This refers to the thickness of material removed in each grinding pass. The CNC machine precisely controls this value to balance productivity with part integrity, allowing for rough grinding followed by fine finishing passes.

- Wheel Rotation Speed

The rotational speed of the grinding wheel affects the cutting efficiency and surface quality. CNC systems adjust the speed in real time to maintain consistent performance, compensate for wheel wear, and match specific grinding conditions.

- Coolant Flow

Controlled coolant delivery reduces frictional heat, flushes away swarf, and protects both the workpiece and the grinding wheel. The flow rate and direction are often dynamically managed to maintain thermal stability and surface integrity during the grinding cycle.

A CNC grinding machine operates through precise, computer-controlled coordination of movement, speed, depth, and coolant flow to achieve high-accuracy material removal.

Types of CNC Grinding Machines

While all CNC grinders share the same basic principles, their configurations vary widely depending on the intended application. There are several types of CNC grinding machines, each designed to handle different part shapes and grinding requirements.

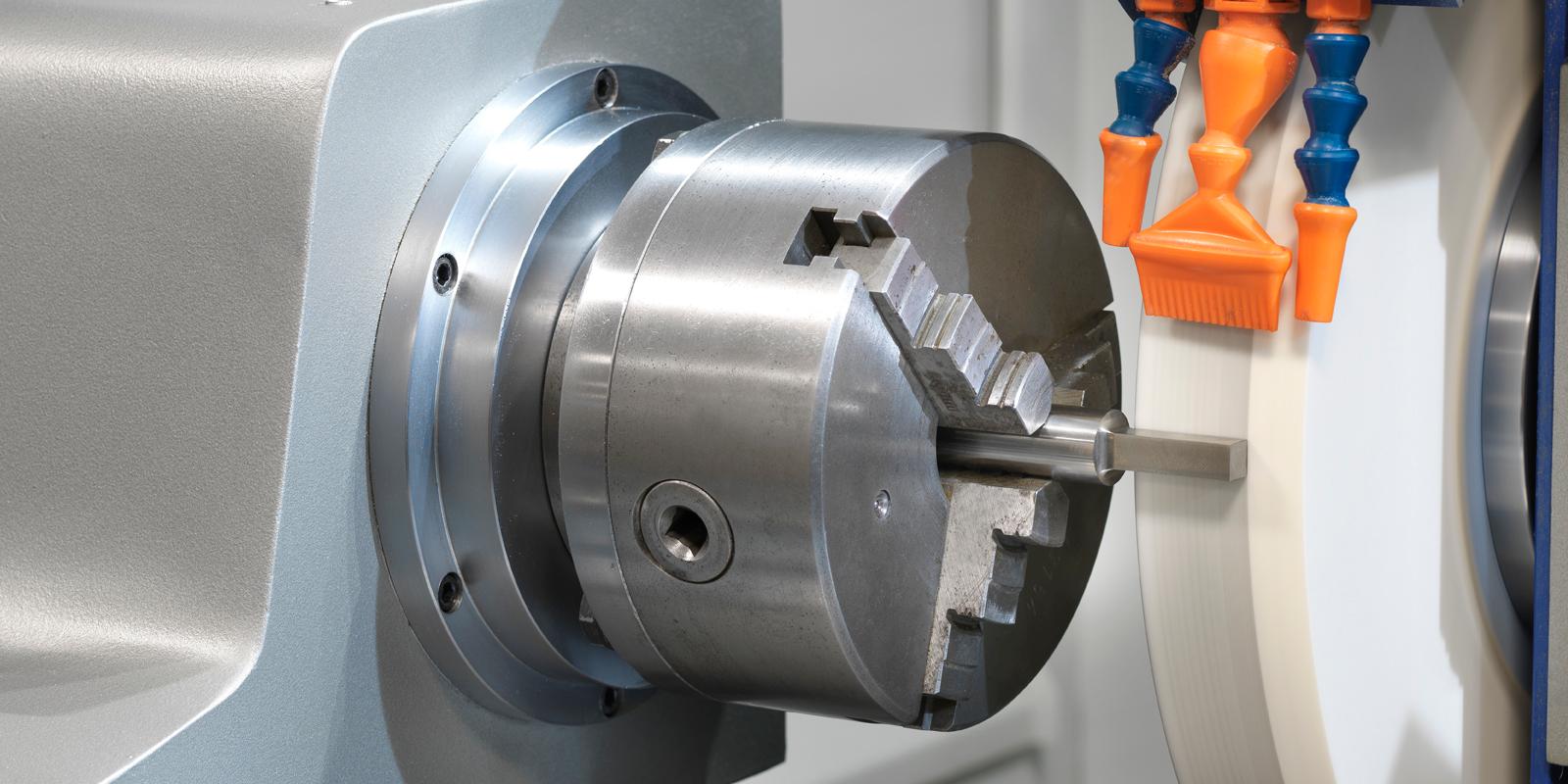

CNC Cylindrical Grinding Machine

CNC cylindrical grinders are designed to grind the outer surface of round or cylindrical workpieces. These machines can perform both external and internal grinding operations, making them ideal for shafts, pins, bushings, and bearing components. Some models offer universal capabilities, allowing for angled or multi-diameter grinding in a single setup.

CNC Surface Grinding Machine

Surface grinders are used to produce flat, smooth surfaces with tight thickness tolerances. In a CNC surface grinding machine, the workpiece is typically held on a magnetic table while a rotating grinding wheel moves over it in programmed patterns.

These machines are commonly used in die and mold making, precision tooling, and parts that require flatness and parallelism. With CNC control, surface grinders can automate fine passes, wheel dressing, and cross-feed movements to maintain consistent surface finish and part quality.

CNC Centerless Grinding Machine

Unlike other grinders that secure the workpiece using chucks or centers, centerless grinding machines support the part between a grinding wheel and a regulating wheel, with no need for clamping.

This design allows for continuous, high-speed throughput, making centerless grinders ideal for mass production of cylindrical parts like pins, rods, tubes, and bushings.

CNC Tool and Cutter Grinder

CNC tool and cutter grinders are specialized machines designed to manufacture and recondition cutting tools such as drills, end mills, and reamers. These grinders typically operate with 5 or more axes to allow complex geometries, helixes, and relief angles to be ground accurately.

The CNC system enables precise programming of tool paths and grinding sequences, ensuring each tool maintains its design specification across multiple resharpening cycles. These machines are critical in tooling departments and cutting tool production lines.

CNC Internal Grinding Machine

CNC internal grinders are specifically engineered to grind internal surfaces, such as bores, holes, and cylindrical cavities, within a part. These machines feature a smaller, narrower grinding wheel that rotates inside the workpiece, with careful control over speed, feed, and positioning.

They are often used for high-precision components like hydraulic cylinders, bearing housings, and precision bushings. CNC programming allows for complex bore profiles and tight tolerances to be achieved consistently, even in small-diameter or deep-hole applications.

Advantages of CNC Grinding

CNC grinding offers several performance advantages over conventional machining methods, especially in high-precision, high-volume manufacturing environments.

Precision and Consistency

CNC grinders achieve exceptionally tight tolerances, often within ±0.001 mm, and deliver consistent results across long production runs. The automated system eliminates human error and ensures repeatability, making it ideal for critical components that require uniformity in every unit.

Complex Geometries

Multi-axis CNC grinding machines can produce intricate shapes, contours, and transitions that are difficult or impossible to achieve with traditional grinding. This capability allows manufacturers to combine multiple operations into one setup, improving accuracy and reducing cycle time.

Material Versatility

CNC grinding is suitable for a wide range of materials—from hardened steels and carbides to ceramics and superalloys. The flexibility in abrasive selection and parameter control enables the process to accommodate both soft metals and extremely hard or brittle materials with minimal surface damage.

Applications of CNC Grinding

CNC grinding plays a vital role in industries where dimensional accuracy, repeatability, and surface integrity are critical to product performance and safety.

Grinding for Automotive

In the automotive industry, CNC grinding is essential for manufacturing high-precision components such as camshafts, crankshafts, transmission gears, and fuel injection parts.

These parts must meet stringent tolerances and wear resistance standards to ensure vehicle reliability and efficiency. CNC grinders support both prototyping and mass production with consistent output.

Grinding for Aerospace

CNC grinding is widely used to produce components for turbines, actuators, and landing gear systems in aerospace applications. These parts often involve exotic materials like Inconel or titanium alloys and require sub-micron precision. The process ensures surface integrity and fatigue resistance in high-stress, high-altitude environments.

Grinding for Tooling and Die Making

Tool and die manufacturers rely on CNC grinding to produce punches, dies, molds, and precision cutting tools. The ability to grind complex geometries and maintain tight tolerances enhances tool life and production quality. CNC tool and cutter grinders also support regrinding to extend tool usage across multiple cycles.

Grinding for Medical Devices

In the medical sector, CNC grinding enables the production of surgical instruments, orthopedic implants, dental prosthetics, and microcomponents with exacting specifications. The process ensures smooth surfaces, precise shapes, and biocompatible finishes necessary for patient safety and performance. Materials such as stainless steel, titanium, and cobalt-chrome are commonly processed.

While these sectors represent the most prominent use cases, CNC grinding is also applicable to energy, defense, electronics, and general industrial manufacturing. Its adaptability to diverse materials and geometries makes it an indispensable process across many precision-driven industries.

Grinding vs Milling

While both milling and grinding are material removal processes, their mechanisms, tools, and outcomes differ significantly. Milling uses rotary cutting tools with defined edges to shear material away in distinct chips, while grinding employs an abrasive wheel composed of thousands of cutting points that wear away the surface in finer increments.

One common misconception is that grinding is always a rougher process, when in fact it often produces much finer finishes and tighter tolerances than milling. Another misunderstanding is assuming they are interchangeable—grinding is typically reserved for high-precision, hard material finishing, whereas milling is better suited for bulk material removal and shaping. We can check the key differences on milling vs grinding by a table here:

| Feature | Milling | Grinding |

| Tool Type | Multi-point cutting tool (e.g., end mill) | Abrasive wheel with thousands of grits |

| Material Removal | Removes material in large, defined chips | Removes material in small, fine increments |

| Surface Finish | Moderate; requires post-processing for fine finishes | Very fine; can achieve sub-micron finishes |

| Precision & Tolerance | Moderate precision | High precision and tight tolerances |

| Application | Shaping, contouring, slotting | Finishing, surface refinement, tight geometry |

| Common Materials | Aluminum, steel, plastics | Hardened steel, carbide, ceramics |

| Heat Generation | Lower than grinding | Higher; requires coolant to manage thermal stress |

| Speed & Feed Rates | Typically higher | Slower to maintain accuracy and finish |

| Use Case | Roughing and structural machining | Finishing and dimensional control |

Conclusion

CNC grinding is a vital precision machining process that offers unmatched accuracy, repeatability, and surface quality across a wide range of materials and industries. As manufacturing demands grow more complex, CNC grinders continue to play a critical role in ensuring performance, reliability, and efficiency in high-precision applications.

Frequently Asked Questions

Q1. What is grinding in CNC?

CNC grinding is a computer-controlled machining process that uses an abrasive wheel to remove precise amounts of material from a workpiece. It is commonly used for achieving tight tolerances, smooth surface finishes, and accurate geometries, particularly in hard or delicate materials.

Q2. What does CNC stand for in grinders?

CNC stands for Computer Numerical Control, which refers to the automated control of machine tools via programmed instructions. In grinders, CNC technology manages movements, speeds, feed rates, and other parameters to ensure consistent and high-precision grinding.

Q3. What is the difference between grinding and milling CNC?

The main difference lies in how the material is removed. CNC milling uses rotating cutting tools with sharp edges to shear off chunks of material, while CNC grinding uses a rotating abrasive wheel to wear away small amounts of material for fine finishes and high precision. Milling is typically used for shaping and bulk removal, whereas grinding is ideal for finishing and tight-tolerance work.

Q4. What does CNC mean?

CNC, or Computer Numerical Control, is a manufacturing technology in which pre-programmed software dictates the movement and operation of machinery. It allows for highly accurate, repeatable, and automated machining processes across various types of equipment, including grinders, lathes, and milling machines.