Food grade stainless steel plays a crucial role in ensuring hygiene, durability, and corrosion resistance. Understanding what makes a material “food grade” can help manufacturers, engineers, and consumers make safer and more informed choices.

In this article, we’ll explore what food grade stainless steel really means, how it’s classified, and why it matters across different applications.

What is Food Grade Stainless Steel?

Food grade stainless steel refers to specific types of stainless steel that are safe to use in applications involving food, beverages, or pharmaceuticals. These materials must meet strict requirements for hygiene, non-toxicity, and corrosion resistance, ensuring they do not react with food or leach harmful substances during use.

What sets food grade stainless steel apart is its ability to withstand repeated exposure to moisture, acids, and cleaning agents without compromising structural integrity or safety. It is non-porous, easy to sanitize, and resistant to rust, even in demanding environments such as commercial kitchens, food processing plants, or marine applications.

While the term “food grade” might sound broad, not all stainless steels are suitable for contact with food. Grades like 304 and 316 are among the most commonly used due to their excellent performance in sanitary conditions. However, selecting the right grade depends on the specific requirements of the application, including exposure to salt, acidity, or high temperatures.

Key Features of Food Grade Stainless Steel

Image: Food Grade Stainless Steel

Corrosion Resistance

Food grade stainless steel must withstand constant exposure to water, food acids, cleaning chemicals, and even salt in some environments. Grades like 304 and 316 are designed to resist corrosion, which is essential for preventing contamination and maintaining the integrity of equipment. In environments where chloride exposure is high, such as in seafood processing, 316 is preferred due to its enhanced resistance.

Non-Reactivity with Food Substances

A critical requirement for any food-contact surface is chemical stability. Food grade stainless steel does not react with acidic or alkaline foods, which helps preserve both food safety and taste. This non-reactivity is one reason stainless steel is widely used in dairy, brewing, and canning operations.

Sanitation

Smooth, non-porous surfaces make food-grade stainless steel easy to clean and sanitize, reducing the risk of bacterial growth. Regulatory bodies like the U.S. FDA and the European Commission require food-contact surfaces to be easily cleanable, with stainless steel often recommended for its superior hygienic properties.

Durability

Food processing environments involve physical wear, from cutting and impact to thermal cycling. Food grade stainless steels retain strength at high and low temperatures, resist denting, and have a long service life even under mechanical stress. This makes them ideal for both industrial equipment and commercial kitchen use.

Resistance to Temperature Extremes

Many food processes involve sudden shifts between hot and cold. Think of sterilization, freezing, or steam cleaning. Food grade stainless steel can tolerate wide temperature variations without deforming, cracking, or losing its protective oxide layer, which is essential to maintaining corrosion resistance.

Surface Finish

The surface finish of stainless steel affects its ability to resist microbial buildup. A fine, smooth finish (often ≤ 0.8 μm Ra) is recommended in sanitary design standards such as those from the European Hygienic Engineering & Design Group (EHEDG) and the USDA. These surfaces are less likely to harbor bacteria and are easier to disinfect.

Common Grades of Food Grade Stainless Steel

Stainless steel comes in several families, each with its own composition and performance characteristics. In food-related applications, the most commonly used are austenitic grades, known for their superior corrosion resistance and formability. However, ferritic and martensitic stainless steels are also used in specific cases where strength or magnetism is required.

Here’s a brief overview of the primary categories:

- Austenitic Stainless Steels (e.g., 304, 316)

These are the most widely used stainless steels in the food industry. They contain high levels of chromium and nickel, offering excellent corrosion resistance and non-magnetic properties. Grade 304 is the standard for most food-contact applications, while grade 316 is preferred in environments with high chloride exposure or acidic ingredients.

Image: Food Grade 304 SS

- Ferritic Stainless Steels (e.g., 430)

Ferritic steels contain chromium but little to no nickel. They are less corrosion-resistant than austenitic grades but are still suitable for less demanding applications such as indoor food equipment and decorative elements. They are also magnetic and more cost-effective.

- Martensitic Stainless Steels (e.g., 420, 440)

These steels are known for their high strength and hardness, making them ideal for items like knives, blades, and cutting surfaces. However, they offer lower corrosion resistance and are typically not used for prolonged contact with moist or acidic foods.

Choosing between these grades depends on the specific application, environmental exposure, and desired properties such as corrosion resistance, strength, or magnetism.

Beyond these commonly used types, other specialized stainless steels, such as duplex or precipitation-hardened grades, may be used in niche food processing scenarios that demand higher mechanical strength, resistance to stress corrosion, or customized performance. However, these are less frequent in standard food-contact applications due to cost, complexity, or processing constraints.

Food Grade Standards and Compliance

The right stainless steel for food contact requires more than just material properties; it must also comply with recognized safety and hygiene standards. These standards ensure the material is safe, non-reactive, and suitable for repeated food exposure under various conditions.

FDA

In the United States, the FDA regulates materials intended for food contact through the Code of Federal Regulations (21 CFR § 177.2600). Stainless steel is considered acceptable for food contact as long as it meets certain compositional requirements and does not leach harmful substances under intended use conditions. The FDA does not certify specific grades, but 304 and 316 stainless steels are widely accepted due to their non-toxicity, corrosion resistance, and cleanability.

NSF International

NSF provides third-party certification for food equipment and materials. Stainless steel components used in commercial food service must often meet NSF/ANSI Standard 51, which covers materials used in food equipment. This includes requirements for corrosion resistance, ease of cleaning, and resistance to staining or degradation. NSF certification is especially important in commercial kitchens, food prep areas, and equipment manufacturing.

ISO

The ISO provides internationally recognized material standards, including ISO 15510, which classifies stainless steels by chemical composition. Additionally, ISO 22000 governs food safety management systems and indirectly influences material selection by requiring sanitary, traceable, and hazard-controlled production environments. While ISO doesn’t specify “food grade” steels directly, its frameworks are used globally to ensure compliance in food processing.

EN

In the EU, stainless steel used for food contact must comply with Regulation (EC) No. 1935/2004, which states that materials should not transfer substances to food in quantities that could endanger human health. While this regulation is material-neutral, specific grades such as 1.4301 (304) and 1.4404 (316L) are often referenced in technical guidance. Additionally, EN 10088 provides specifications for stainless steel grades and compositions relevant to food use.

3-A Sanitary Standards

Used primarily in the dairy and beverage industries in the U.S., 3-A Sanitary Standards define criteria for sanitary design, including surface finish, construction, and cleanability of stainless steel components. These standards are particularly stringent and often require a No. 4 surface finish (Ra ≤ 0.8 μm) to prevent bacterial accumulation. Compliance with 3-A is critical in high-purity processing environments like dairy, brewing, and pharmaceuticals.

EHEDG

EHEDG provides design guidelines for hygienic equipment used in food manufacturing. While not a regulatory body, its recommendations are widely adopted across Europe and increasingly recognized worldwide. EHEDG guidelines emphasize surface finish, material compatibility, and clean-in-place (CIP) capability. Stainless steel used in EHEDG-compliant equipment must meet stringent hygienic design criteria to minimize microbial risk.

Choosing the Right Food Grade Stainless Steel

Selecting the right stainless steel for a food-related application isn’t just about choosing the highest grade; it’s about matching the material to the environment in which it will perform.

Image: Food Grade 316L SS

1. Food Type, Exposure, and Cleaning

Different foods interact with stainless steel in different ways. For instance, high-acid foods like tomatoes or citrus can accelerate corrosion in lower-grade steels. Likewise, environments with high salt content, such as seafood processing, require enhanced corrosion resistance, often making 316 stainless steel the better choice over 304.

The cleaning process is another critical factor. Frequent use of strong sanitizers, high-pressure washdowns, or steam cleaning demands a steel grade that can endure chemical and thermal stress without degrading or corroding.

2. Industrial vs. Consumer Use

In industrial settings, food grade stainless steel must meet stricter regulatory standards, endure longer duty cycles, and perform reliably under high temperatures, impact, or mechanical load. Equipment in food processing plants, commercial dairies, or breweries often uses higher grades and certified finishes.

In contrast, consumer products like kitchen sinks, cookware, or cutlery prioritize affordability, aesthetic appeal, and moderate corrosion resistance. Here, 304 or 430 stainless steel is sufficient, though it may require more frequent maintenance.

3. Cost, Longevity, and Maintenance

Higher-grade stainless steels such as 316 or duplex alloys come at a premium, but they offer superior resistance to corrosion and wear, reducing long-term maintenance costs and equipment downtime. In high-throughput environments, this investment pays off over time.

However, in low-risk, low-exposure scenarios, a less expensive option may be entirely adequate if paired with proper maintenance routines. Evaluating total lifecycle cost, not just material price, is essential in making an informed decision.

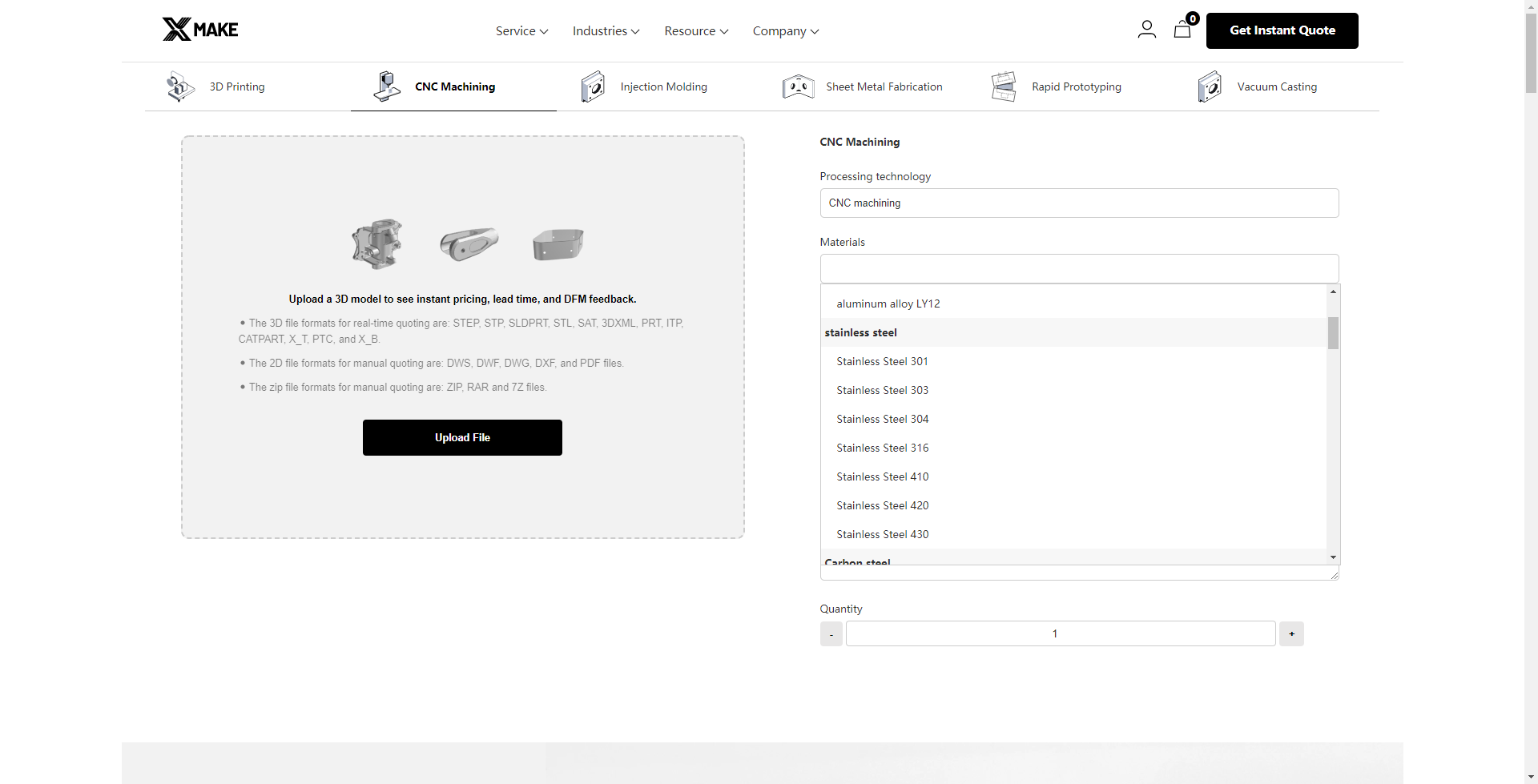

CNC Machining Food Grade Stainless Steel

CNC machining is one of the most reliable and precise methods for producing components made from food grade stainless steel. Whether you’re manufacturing mixing blades, valve bodies, or sanitary fittings, CNC processes ensure high dimensional accuracy and smooth surface finishes, both of which are essential for hygiene and compliance in food-contact environments.

At Xmake, we offer CNC machining services using common food grade stainless steel alloys such as 304, 316, and 316L. These materials are carefully selected and processed to meet both structural and regulatory requirements.

If your application demands custom stainless steel parts with strict tolerances, corrosion resistance, and food safety assurance, CNC machining provides a scalable and dependable solution.

Conclusion

Food grade stainless steel plays a vital role in maintaining safety, hygiene, and durability in both industrial and consumer food environments. Choosing the right grade and the right manufacturing partner ensures long-term performance and peace of mind.

Frequently Asked Questions

1. Is 304 stainless steel food grade?

Yes, 304 stainless steel is widely considered food grade and is one of the most commonly used materials in the food industry. It offers excellent corrosion resistance, is easy to clean, and does not react with most food products. From commercial kitchen sinks to beverage tanks, 304 is often the default choice for safe, hygienic contact with food.

2. Is 316 stainless steel food grade?

Absolutely. 316 stainless steel is not only food grade, it’s a premium option. It offers even better corrosion resistance than 304, especially in environments with salt, acidic foods, or aggressive cleaning agents. This makes it a preferred choice for seafood processing, dairy production, and other demanding food applications.

3. Which is better, 304 or 316 stainless steel?

304 is highly versatile, cost-effective, and sufficient for most standard food applications. But if your process involves salt, acids, or high humidity, 316 offers superior protection and longer service life. In short: 304 is ideal for general use; 316 is better when conditions demand more resilience.