Driving Automotive Innovation

Our dedication to the progression of automotive technology and services is designed to not only optimize current ventures but also to strategically engineer for future success, securing a leading position in the rapid evolution of the industry.

- Efficient Rapid Prototyping

- State-of-the-Art Technology Integration

- Tailored Innovative Solutions

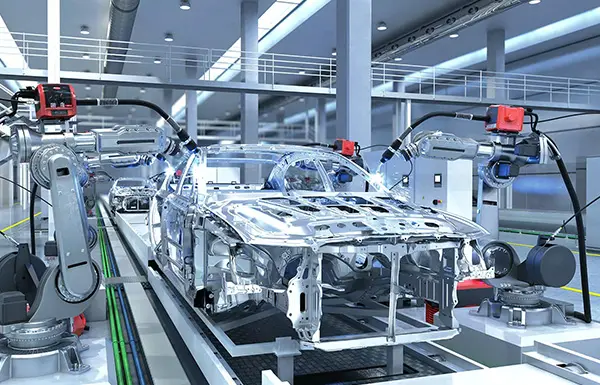

Expertise in Automotive Manufacturing

Auto Design Prototyping: Sketch to Realization

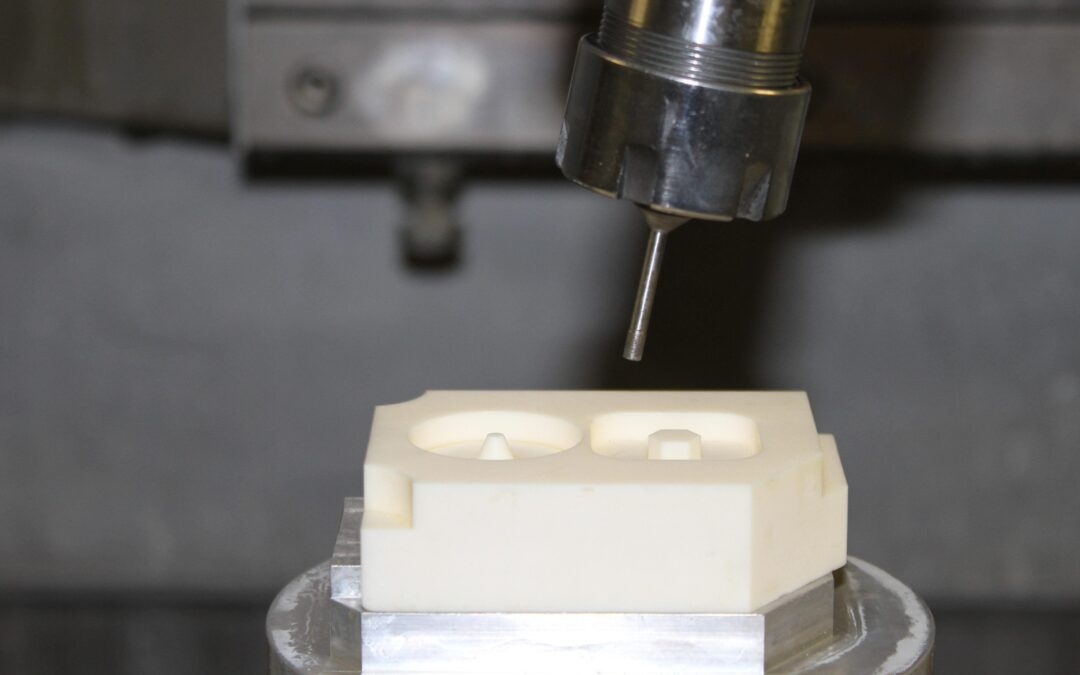

The preliminary phase of automotive design involves translating initial sketches into tangible prototypes. This critical step enables us to refine our concepts, ensuring the final vehicle aligns with our precise vision and stringent standards.

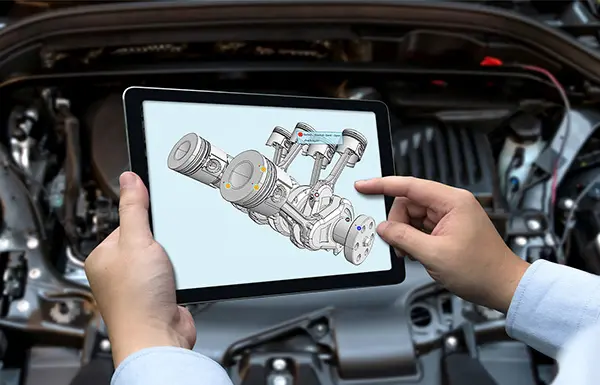

Technical Performance Evaluation

Upon finalizing a robust prototype, we initiate Technical Performance Testing (TPT). This phase rigorously examines the vehicle's engineering and technical competencies, including engine efficiency and safety systems, to guarantee road-readiness across diverse driving conditions.

Product Durability Assessment

Product Endurance Testing (PET) rigorously evaluates our vehicle's durability under simulated real-world conditions, encompassing extreme weather and challenging terrains. This process ensures the vehicle's safety and resilience, guaranteeing a dependable and long-lasting product for our clientele.

Readiness Assessment for Manufacturing

Prior to initiating full-scale production, Manufacturing Readiness Testing (MRT) verifies our vehicle's suitability for mass production. This phase scrutinizes the production process, ensuring scalability without quality compromise. It represents the ultimate validation step, confirming preparedness from assembly operations to supply chain logistics.

Scaling Production with Quality and Performance

We commence scaled production post-verification, translating our vehicle from concept to consumer. We prioritize the preservation of superior quality and performance benchmarks established in prior stages, assuring each vehicle satisfies automotive industry customer expectations.

Why Automative Companies Choose XMAKE

Trusted by Engineers at Leading Automotive Companies

- Lighting Features and Lenses

- Plastic Dash Components

- Assembly Line Components

- Vehicular Consumer Electronics

- Autonomous Vehicle Sensors

- Electric Bikes and Scooters

Automotive FAQs

1. How does digital manufacturing with XMAKE impact the advancement of automotive technology?

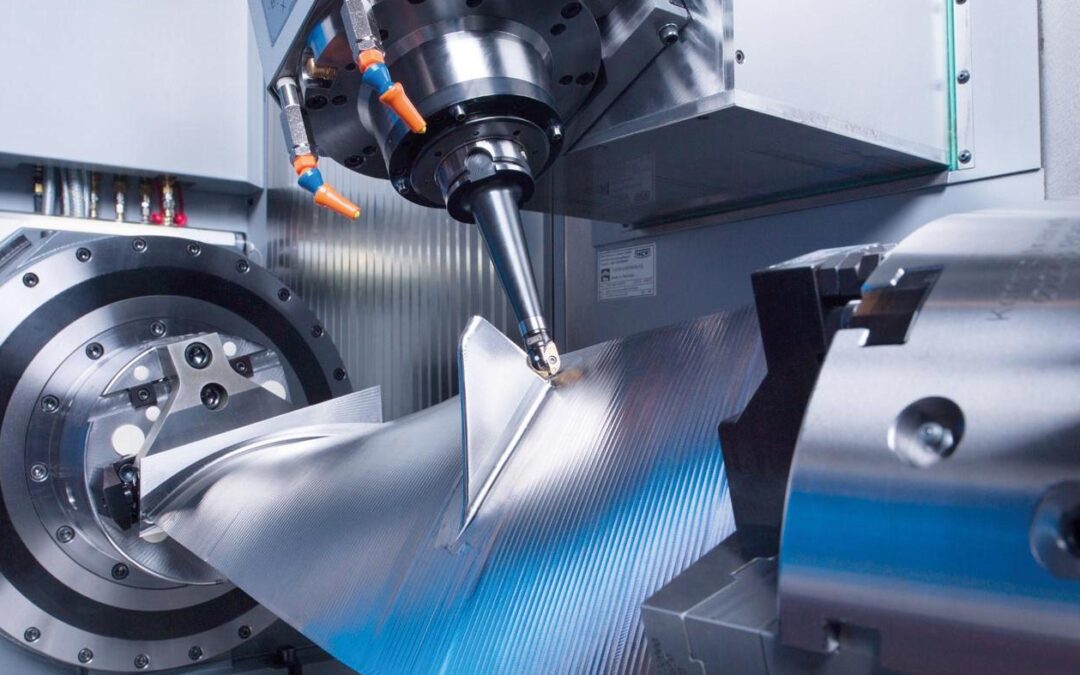

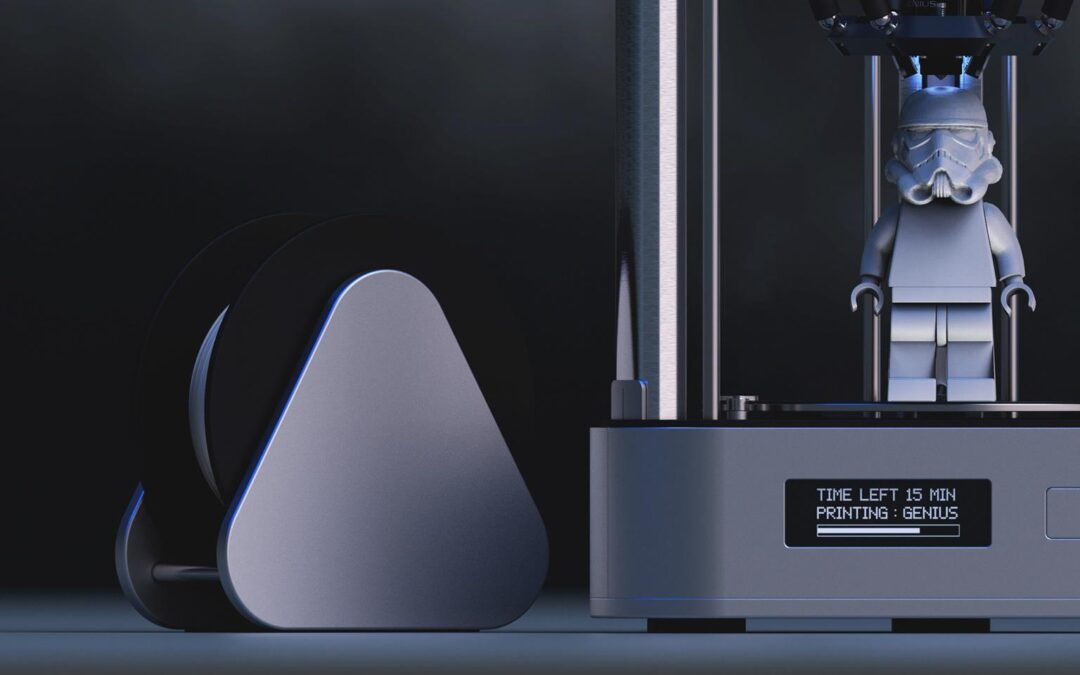

XMAKE's digital manufacturing platform revolutionizes automotive technology by enabling the production of complex components with high precision and efficiency. This technology facilitates rapid prototyping and small-batch production, accelerating the development of innovative automotive parts and systems.

2. What kind of automotive services does XMAKE provide in terms of component customization?

XMAKE offers a range of services tailored to automotive component customization. We leverage advanced 3D printing and CNC machining to produce components that meet specific design requirements, allowing for greater personalization and performance optimization in the automotive industry.

3. How does XMAKE ensure the quality and durability of automotive components manufactured through digital processes?

XMAKE ensures quality and durability through stringent quality control measures and the use of high-grade materials suitable for the demanding conditions of the automotive industry. Each component undergoes rigorous testing to meet or exceed industry standards for performance and longevity.

4. What role does XMAKE’s digital manufacturing play in the cost-effectiveness of automotive component production?

XMAKE's digital manufacturing processes are designed to be cost-effective, reducing the need for extensive tooling and allowing for on-demand production. This not only lowers upfront costs but also provides flexibility for manufacturers to respond quickly to market changes and component demand.

5. How does XMAKE contribute to the future of automotive technology and services with sustainable manufacturing practices?

XMAKE is committed to sustainable manufacturing practices, which are integral to the future of automotive technology and services. We implement processes that minimize material waste, reduce energy consumption, and utilize recyclable materials where possible, all while maintaining the highest standards of component quality and performance.

Join Us to Innovate Faster and Better

-

All uploads are secure and confidential.

All uploads are secure and confidential.

Learn More about Automotive Resources

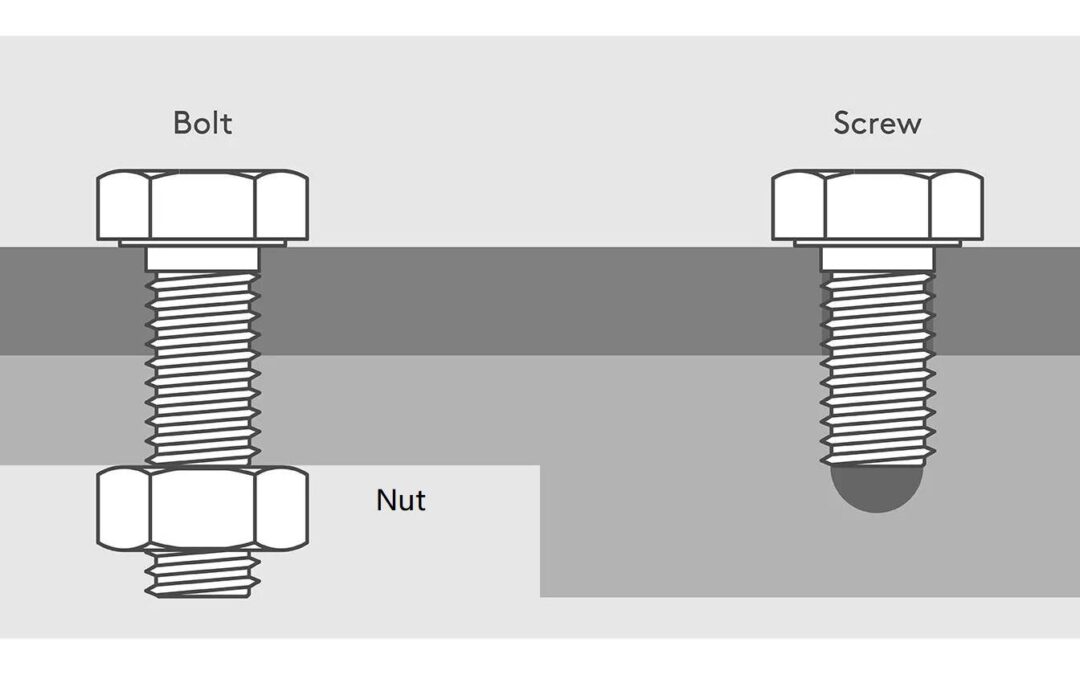

Nut vs Bolt: What is the Difference?

Explore the essential differences in nut vs bolt, including their types, materials, and best applications. Learn how to choose and maintain the right fasteners for your needs.

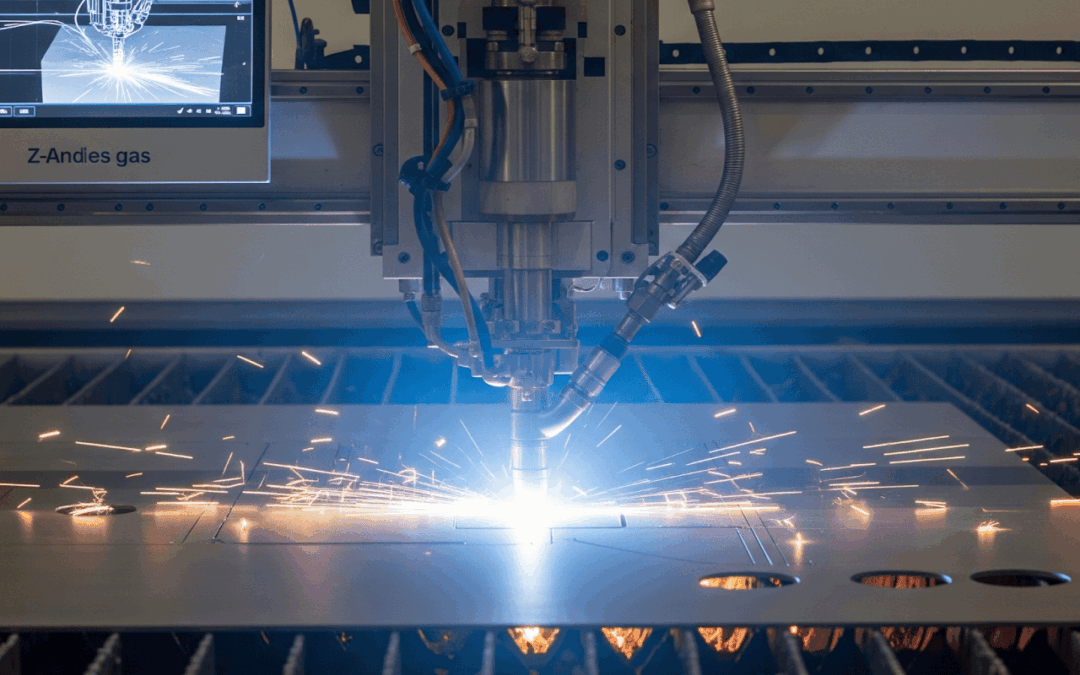

CNC Plasma Cutter: How It Works, Benefits & Selection Tips

Explore how a CNC Plasma Cutter cuts metal with precision. Learn key benefits, speed, thickness capacity, tolerance and how to choose the right system.

Different Types of CNC Machines

Explore the most common types of CNC machines, how they work, and their applications. Learn which CNC machine suits your needs in this complete guide.

How to DIY a 3D Printed Airless Basketball?

Creating a 3D printed airless basketball is a rewarding DIY project that blends creativity with functional design. Xmake offers a convenient online 3D printing service for you.

How to DIY a 3D Printed Dragon?

DIY a 3D printed dragon from start to finish with this step-by-step guide, learn how to find models, prepare files, print, and post-process like a pro.

12 Different Types of 3D Printing [Full Guide]

Explore 12 different types of 3D printing. Learn how to choose the right type and find professional 3D printing services for your project needs.

Knurling: Everything You Need to Know

Knurling is a crucial machining process that enhances grip, aesthetics, and assembly performance. This guide covers knurling types, usages, and standards.

What is Titanium 3D Printing?

Titanium 3D printing represents an advancement in metal additive manufacturing, enabling the production of lightweight, high-strength parts with complex geometries.

All About Ceramic CNC Machining

Explore ceramic CNC machining, including common types of ceramic materials, processes, and key applications. Learn how precision CNC processes handle advanced ceramics.

What Are the Different Types of Pins?

Pin fasteners are essential in mechanical assemblies. Learn the different types of pins, their uses, functions, and how to choose the right pin for your project.