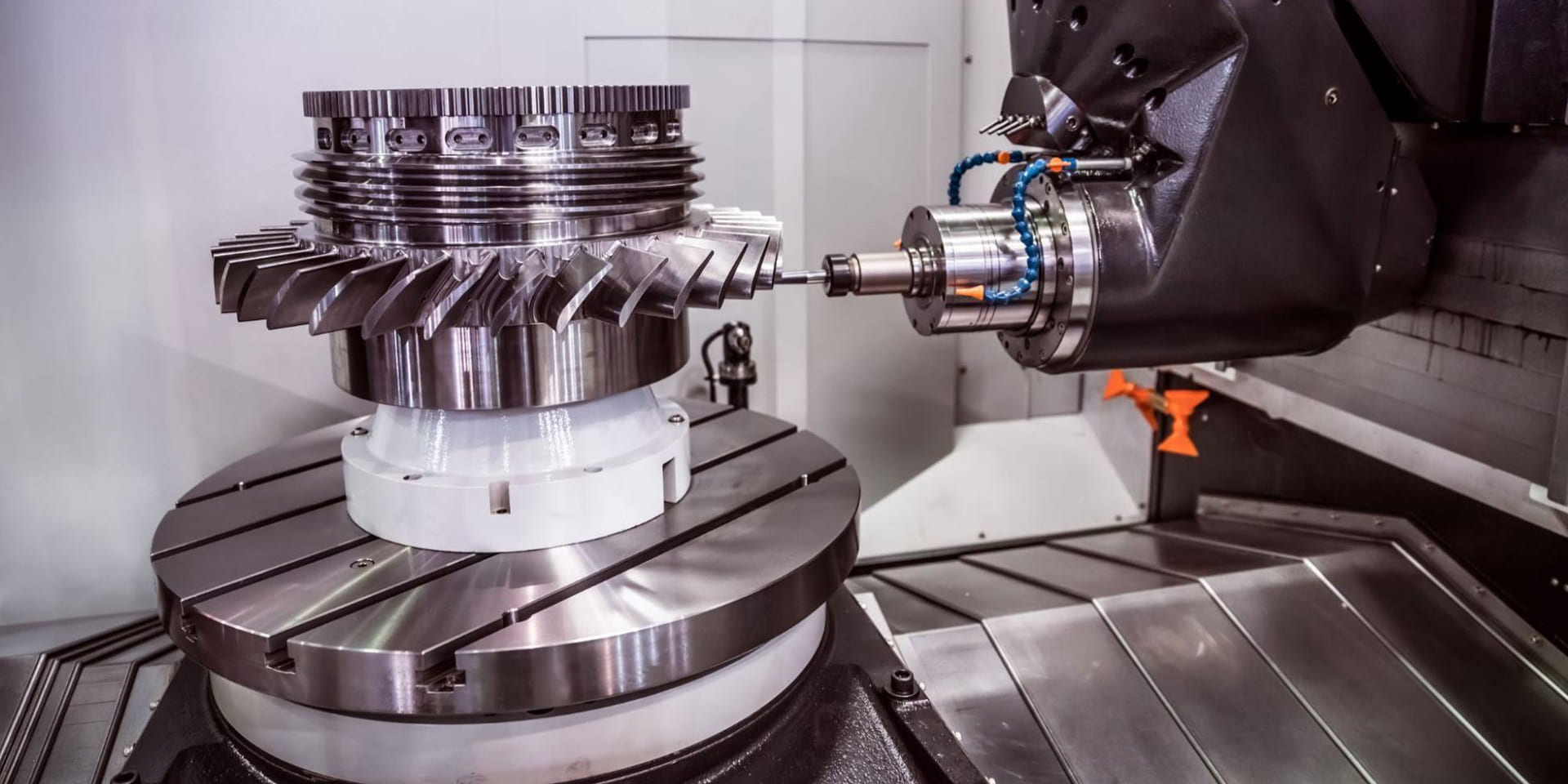

If you’ve ever held a perfectly machined metal part and wondered how something so precise was made, chances are, CNC milling was involved. From aerospace components to smartphone casings, this technology is quietly behind many of the objects we rely on every day, cutting, shaping, and carving with remarkable accuracy.

In this guide, we will learn:

- What CNC milling is and how it works

- The main components and types of CNC milling machines

- What materials can be milled and how the process is applied across industries

- The benefits and limitations of using CNC milling for manufacturing

What Is CNC Milling?

CNC milling is a subtractive manufacturing process that uses computer-controlled rotary cutters to remove material from a solid workpiece.

In practical terms, it’s one of the core methods used to create parts with tight tolerances, smooth finishes, and complex shapes — all with remarkable consistency. In today’s manufacturing workflows, CNC milling is often the go-to choice for producing components that demand precision, especially when working with metals, plastics, or composites.

So, what is CNC milling in modern production? It’s a highly adaptable process that bridges digital design with real-world functionality. Once a part is modeled on a computer, CNC milling brings it to life with precise tool movements, translating data into physical form — often within hours, not days. It’s this direct link between code and cutting that makes CNC milling a cornerstone of efficient, modern manufacturing.

How Does CNC Milling Work?

At its core, CNC milling is a step-by-step process that transforms a digital design into a precisely cut physical part. It follows this sequence:

- Design: A 3D model is created using CAD (Computer-Aided Design) software.

- Programming: The model is converted into a set of machining instructions.

- Setup: The material is fixed onto the machine bed, and the appropriate tool is loaded.

- Machining: The CNC mill removes material using rotary cutting tools along programmed paths.

- Finishing: The part may undergo deburring, surface treatments, or quality checks.

This flow relies heavily on the CAD-to-CAM-to-machine digital chain. First, engineers or designers build a detailed part model in CAD software, specifying dimensions, features, and tolerances. That file is then imported into a CAM (Computer-Aided Manufacturing) program, where the toolpaths, cutting speeds, and depths are defined.

The CAM software generates a numerical control file, most often in the form of G-code, which contains all the instructions the milling machine needs to follow. Once the code is verified and optimized, it’s sent to the CNC mill to begin production.

G-code is the machine’s language, a series of simple, line-by-line commands that tell it exactly how to move. It controls everything from spindle speed to tool direction, guiding the cutting process with precise coordination. Without G-code, CNC milling would be little more than a motionless hunk of metal.

Key Components of a CNC Mill

A CNC milling machine is built for precision, repeatability, and control. While models vary in size and capability, most machines share a common structural foundation:

- Spindle: The heart of the machine. This motor-driven component rotates the cutting tool at high speeds, delivering the power needed to cut through metal, plastic, or other materials.

- Bed (or Table): The surface that supports the workpiece during machining. It often includes T-slots or vacuum systems for clamping parts securely in place.

- Axes: CNC mills operate along multiple axes (usually X, Y, and Z) to allow movement in three dimensions. Additional rotary axes may be added for more complex operations.

- Controller: The “brain” of the machine. It reads G-code instructions and translates them into precise movements and tool operations.

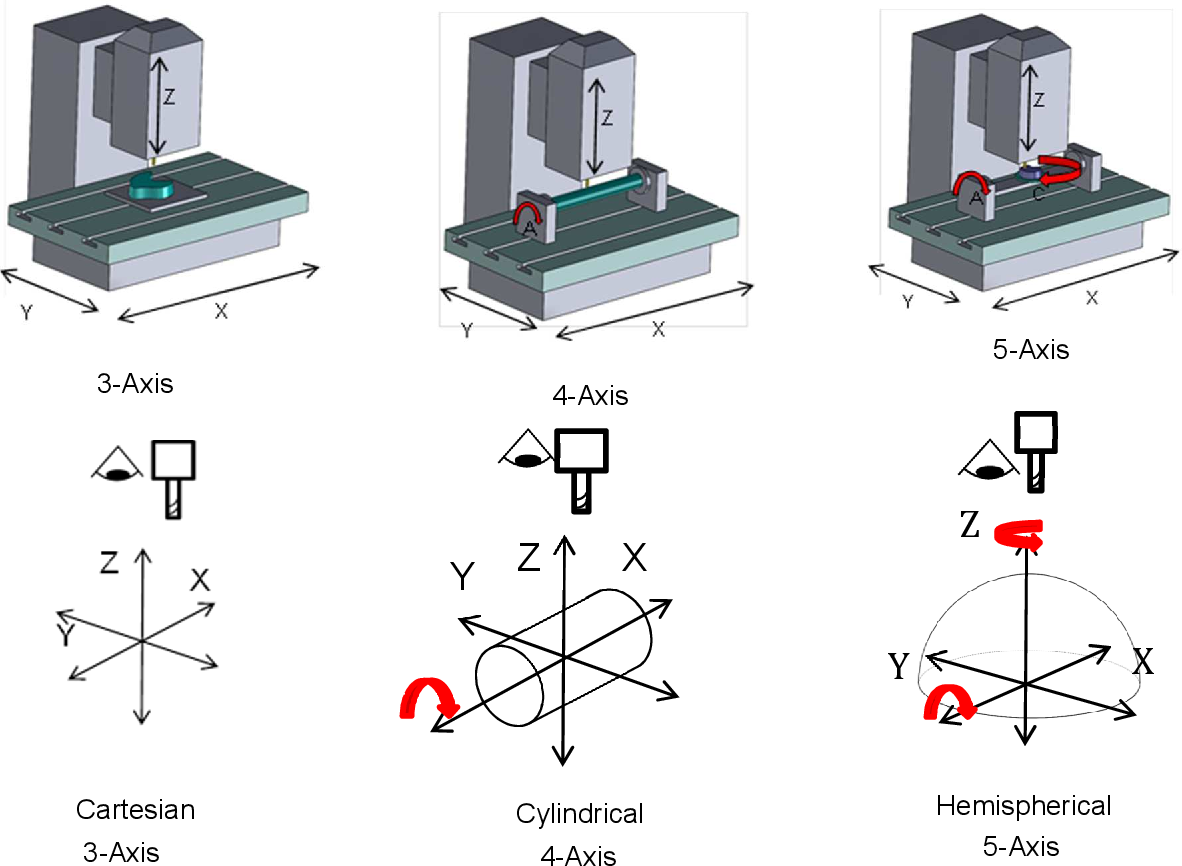

3-Axis vs. 4-Axis vs. 5-Axis Setups

The number of axes in a CNC mill determines how the machine can move and orient the cutting tool or workpiece. Here’s a simple comparison:

|

Axis Setup |

Movement Capabilities |

Use Cases |

|

3-Axis |

X (left-right), Y (front-back), Z (up-down) |

Flat surfaces, basic pockets and holes |

|

4-Axis |

Adds rotation around X or Y axis (usually A-axis) |

Complex profiles, gear cutting |

|

5-Axis |

Adds two rotational axes (often A and B) |

Sculpted surfaces, multi-face machining |

With more axes, the machine can reach more angles and produce more intricate geometries without repositioning the part. This saves time and improves accuracy, especially for parts with curved or angled features.

CNC Mill vs Other CNC Machines

CNC milling machines are distinct in how they remove material, using rotating cutting tools that move across a stationary or semi-stationary workpiece. This contrasts with machines like CNC lathes, which rotate the part itself while the cutting tool remains relatively static.

Another key difference lies in geometry: CNC mills excel at producing prismatic shapes with flat surfaces, slots, and pockets, while CNC lathes are better suited for cylindrical parts. CNC routers, often confused with mills, typically operate at higher speeds with lower torque and are used for softer materials like wood or plastics.

In short, what sets a CNC mill apart is its versatility, cutting strength, and ability to machine hard materials with exceptional precision in multiple directions.

Types of CNC Milling Machines

CNC milling machines come in various configurations, each tailored to specific manufacturing needs. The differences lie in how the machine is built, how the tool engages with the material, and what type of parts it’s best suited to produce.

Vertical CNC Milling Machines

Vertical mills have a vertically oriented spindle, meaning the cutting tool moves up and down. The workpiece is fixed on a horizontal bed while the tool descends to cut. This setup offers excellent visibility during machining and is ideal for flat surfaces, shallow cavities, and straightforward operations.

Vertical CNC mills are widely used in general-purpose manufacturing and prototyping.

Horizontal CNC Milling Machines

In horizontal mills, the spindle is mounted horizontally, allowing the cutting tool to approach the workpiece from the side. This configuration makes it easier to machine deeper cavities and complex shapes, especially in heavy parts.

Horizontal mills often use arbor-mounted tools and are well-suited for high-volume production and material removal in bulk.

Gantry CNC Milling Machines

Gantry mills feature a large bridge-like structure with a moving spindle suspended from above. The table may remain stationary or move beneath the gantry. These machines provide exceptional rigidity and large work envelopes, making them ideal for machining oversized parts such as molds, aerospace structures, and panels.

Bed-Type CNC Milling Machines

Bed-type mills have a fixed table and a movable spindle head that travels vertically and horizontally along the machine frame. This design offers more stability when machining heavy or long workpieces.

Bed mills are often used in applications that require more power and cutting depth than a standard vertical mill can deliver.

Turret CNC Milling Machines

Turret mills are typically smaller machines with a rotating turret that allows the spindle head to move in multiple directions. These are often found in toolrooms or workshops where flexibility and manual intervention are important.

While not as rigid or powerful as other types, turret mills are useful for small parts, one-off jobs, and maintenance work.

Common Materials for CNC Milling

CNC milling is highly adaptable when it comes to material choice.

Metals

- Aluminum: Lightweight, corrosion-resistant, and easy to machine. It’s one of the most popular materials for CNC milling, especially in the aerospace, automotive, and electronics industries.

- Steel: Offers excellent strength and durability, but requires tougher tools and slower feeds. Common in industrial equipment, structural components, and precision tooling.

- Stainless Steel: Known for its corrosion resistance and clean finish, but it’s more difficult to machine due to its hardness and work-hardening behavior.

- Brass: Milled easily with minimal tool wear. Its low friction makes it ideal for fittings, valves, and decorative parts.

- Titanium: Strong, lightweight, and biocompatible — frequently used in aerospace and medical parts. However, it’s notoriously tough on tools and demands careful heat management.

Plastics

- ABS: A widely used thermoplastic with good toughness and machinability. Common in consumer products and enclosures.

- Nylon: Strong, lightweight, and resistant to wear, but it can absorb moisture, which affects dimensional stability.

- PEEK: High-performance plastic with excellent mechanical strength and chemical resistance. Used in aerospace and medical applications where metal alternatives are unsuitable.

- Polycarbonate: Transparent, tough, and dimensionally stable. Useful for protective covers and enclosures requiring optical clarity.

- Acetal (Delrin): A low-friction, high-stiffness plastic that machines very cleanly. Ideal for tight-tolerance parts like bushings, gears, and sliding components.

Material choice directly influences tool selection, cutting parameters, and even machine configuration. Softer plastics can tolerate faster speeds but need sharp tools to avoid melting or surface defects. Harder metals, on the other hand, demand slower feeds and high-performance tooling to maintain accuracy and prolong tool life.

In CNC milling, selecting the right material isn’t just about the final application — it’s also about machining efficiency, part quality, and overall production cost.

CNC Milling: Pros and Cons

Like any manufacturing method, CNC milling comes with its advantages and limitations. The table below offers a quick overview to help you weigh its strengths and trade-offs:

|

Pros |

Cons |

|

High precision and repeatability |

Higher initial investment (machines and setup) |

|

Supports complex geometries and tight tolerances |

Limited efficiency for very high-volume production |

|

Works with a wide range of materials |

Tool wear and maintenance can add costs over time |

|

Automated process reduces human error |

Not ideal for parts with deep internal cavities |

|

Quick turnaround from digital design to part |

Setup and programming require skilled operators |

|

Scalable from prototyping to low–mid production |

Some geometries may require multi-axis setups |

This balance of performance and flexibility is why CNC milling remains a core process in modern machining.

Applications of CNC Milling in Manufacturing

CNC milling is used across countless manufacturing sectors thanks to its precision, flexibility, and ability to handle both simple and highly complex parts.

One of the key reasons CNC milling is preferred in high-precision industries is its ability to achieve tight tolerances and clean surface finishes, even on hard-to-machine materials.

Since every movement is controlled by pre-programmed code, human error is greatly minimized, making the process ideal for critical components where accuracy is non-negotiable.

Here are some typical parts made using a CNC mill:

- Engine components such as cylinder heads, housings, and brackets

- Custom jigs and fixtures for assembly lines

- Housings and enclosures for electronics and medical devices

- Mold cavities and tooling inserts

- Mounting plates, panels, and machine frames

- Gears, bushings, and linkage components

- Heat sinks, connectors, and sensor mounts

These applications span industries such as aerospace, automotive, robotics, medical, defense, and consumer electronics — all of which demand reliable, repeatable results that CNC milling delivers day in and day out.

Partnering with Xmake

CNC milling continues to be one of the most versatile and dependable machining methods in modern manufacturing. With its ability to deliver tight tolerances, complex geometries, and consistent results across a wide range of materials, it’s no surprise that engineers and product developers around the world rely on this process every day.

Whether you’re looking to prototype a single part or scale up to low- or mid-volume production, a CNC mill offers the precision and flexibility needed to bring your designs to life. Choosing the right milling machine with CNC capabilities ensures your parts are made efficiently, accurately, and on time.

At Xmake, we provide professional CNC milling services with no minimum order quantity. Our global manufacturing network, fast quoting platform, and experienced engineering team make it easy to turn your CAD models into production-ready components reliably and affordably.

FAQs

1. What can you make with a CNC milling machine?

You can make brackets, housings, molds, gears, and precision parts for industries like automotive, aerospace, and electronics. It’s ideal for both simple shapes and complex 3D geometries.

2. What is the difference between CNC milling and CNC turning?

CNC milling uses a rotating tool to cut a stationary workpiece, while CNC turning spins the material against a fixed cutting tool. Milling is better for flat or complex surfaces; turning is best for round parts.

3. How much does CNC milling cost?

Costs vary based on material, part complexity, and quantity. Simple parts may cost under $100, while complex or low-volume jobs can be higher due to setup and programming time.