Nuts and bolts are among the most fundamental components in mechanical assembly, yet their differences are often misunderstood. This guide breaks down the distinctions and practical uses of each to help you make informed decisions.

What Are Nuts and Bolts?

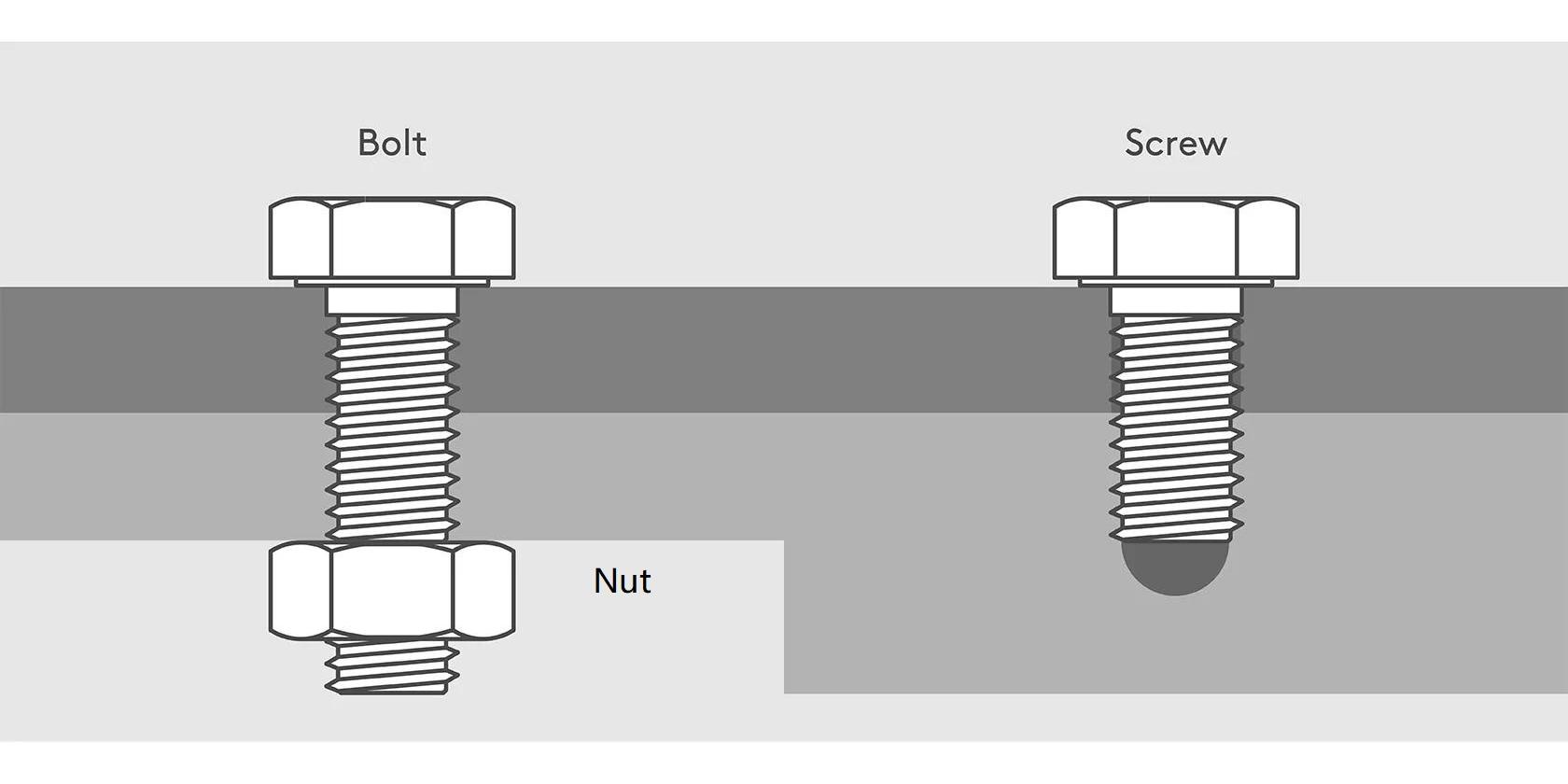

Nuts and bolts are a paired fastening system used to securely join two or more components together, typically in mechanical or structural applications.

Nuts

A nut is a small, typically hexagonal fastener with internal threads. It’s designed to screw onto a bolt to secure materials together. Common nut types include hex nuts, lock nuts, and wing nuts, each playing a specific role in ensuring the bolt remains tightly fastened under various conditions. Nuts are often used in combination with washers to distribute pressure and prevent loosening evenly.

Bolts

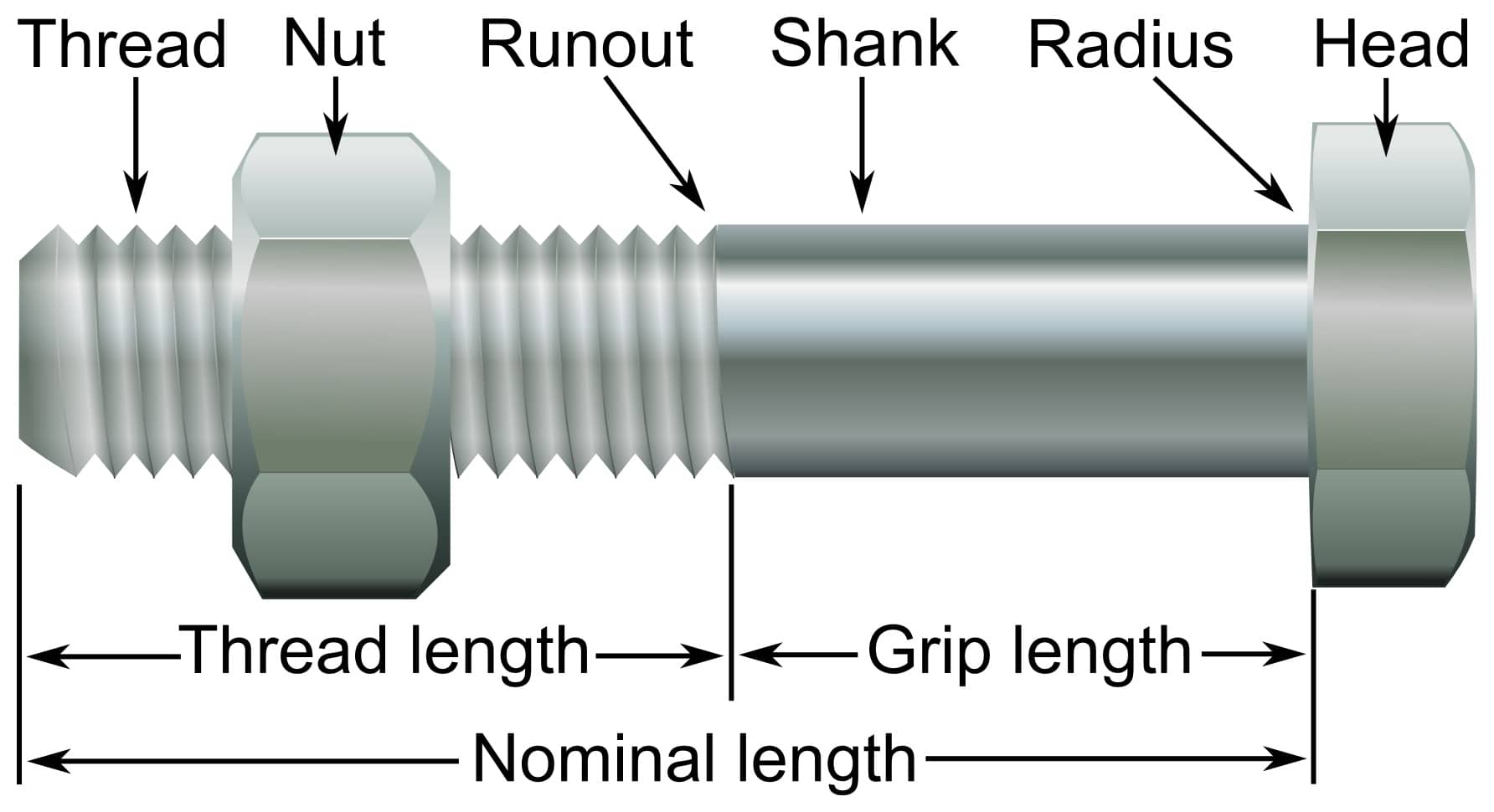

A bolt is a long, threaded fastener with a head on one end, usually requiring a wrench or socket for tightening. It passes through pre-drilled holes in the assembled parts. Bolts are often paired with nuts, but some are used with tapped holes or threaded inserts.

External vs Internal Threading

Bolts feature external threading, meaning the threads wrap around the outside of the shaft. Nuts have internal threading, which spirals along the inside of the hole. The threads must match in diameter and pitch to form a tight, secure fit. This interlocking design is what enables reliable fastening.

Fastening System

Together, nuts and bolts form a dependable fastening system that can be tightened or loosened as needed. When the bolt is inserted through the materials and the nut is threaded onto it, torque is applied to generate clamping force. This system is widely used due to its strength, simplicity, and reusability. Properly installed, it can handle significant mechanical stress without permanent deformation.

What’s the Difference Between Nuts and Bolts?

Although nuts and bolts are designed to work together, they serve very different roles in the fastening system:

- A bolt acts as the main connector, inserted through materials to provide the clamping force.

- A nut holds the bolt in place by threading onto it and locking the assembly from the opposite side.

Structure: Bolts have a head and a partially or fully threaded shaft, while nuts are compact and internally threaded with no head.

Function: Bolts typically bear the load and provide tension, while nuts react to that load to secure everything in place.

Installation: Bolts are often turned using a wrench or socket at the head, whereas nuts are tightened from the opposite side, either manually or with a tool. This dual-sided engagement is what makes them so effective as a mechanical fastener pair.

Bolt vs Nut

|

Feature |

Bolt | Nut |

| Threading | External threads (on the shaft) | Internal threads (inside the body) |

| Shape | Long shaft with a shaped head | Small, compact, usually hexagonal |

| Function | Applies tensile (pulling) force to hold components together | Resists compressive force and prevents loosening |

| Common Type | Hex bolt, carriage bolt, anchor bolt, eye bolt, lag bolt, etc | Hex nut, lock nut, wing nut, flange nut, cap nut, etc |

| Tools Required | Wrench or socket for the bolt head | Wrench, socket, or hand (for wing nuts) |

| Common Use | Connects and aligns components | Secures and stabilizes the connection |

Read more: What Are the Different Types of Pins?

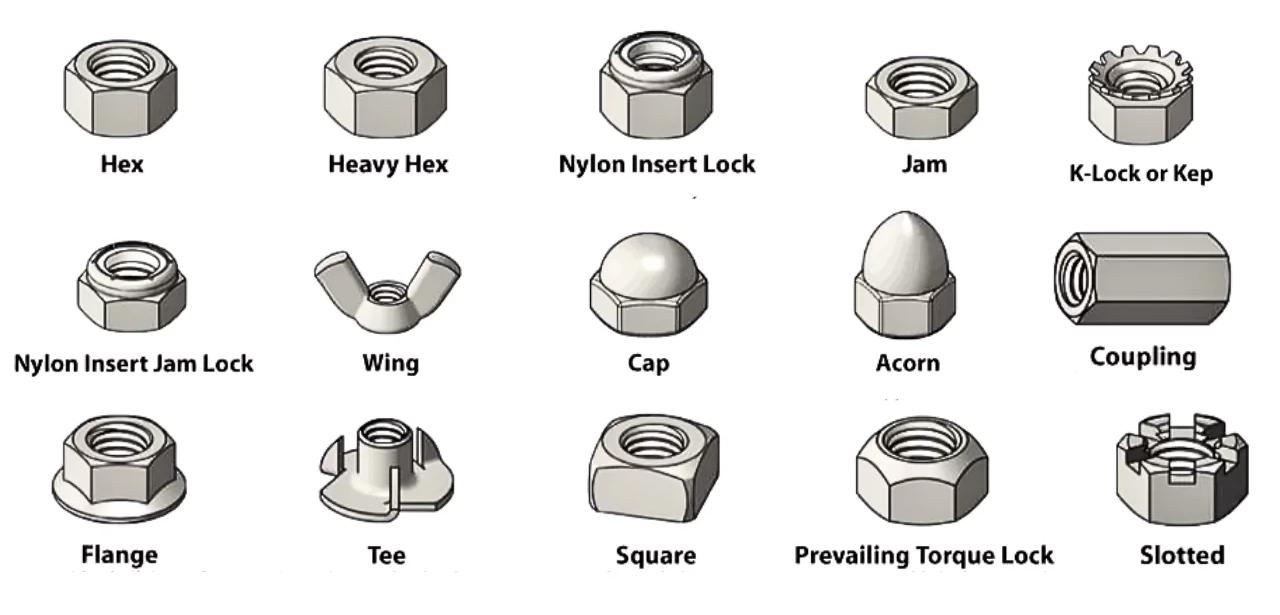

Common Types of Nuts

Nuts come in various shapes and designs to accommodate different fastening requirements, from general-purpose use to vibration resistance.

Image: Types of Nuts

Hex Nut

The hex nut is the most common type, featuring six sides for easy grip and torque application. It is used in general fastening applications and pairs well with standard bolts. Hex nuts are simple, reliable, and widely available in different sizes and materials.

Lock Nut

A lock nut is designed to resist loosening caused by vibration or repeated motion. It often incorporates a nylon insert or a distorted thread to create friction against the bolt. This added resistance helps maintain joint integrity in demanding environments like machinery or automotive systems.

Wing Nut

Wing nuts have two flat projections, or “wings,” that allow for hand tightening without tools. They’re commonly used in applications requiring frequent adjustments or disassembly. Their design makes them convenient for light-duty, non-critical fastening tasks.

Flange Nut

Flange nuts have a wide, built-in washer-like base that distributes pressure more evenly across the surface. This design helps prevent material deformation and eliminates the need for a separate washer. Flange nuts are especially useful in automotive and heavy-duty mechanical applications.

Cap Nut

Cap nuts, also known as acorn nuts, have a domed top that covers the exposed end of the bolt. This design not only provides a finished appearance but also protects threads from damage or corrosion. They’re commonly used in decorative applications, furniture assembly, and where safety or aesthetics are a concern.

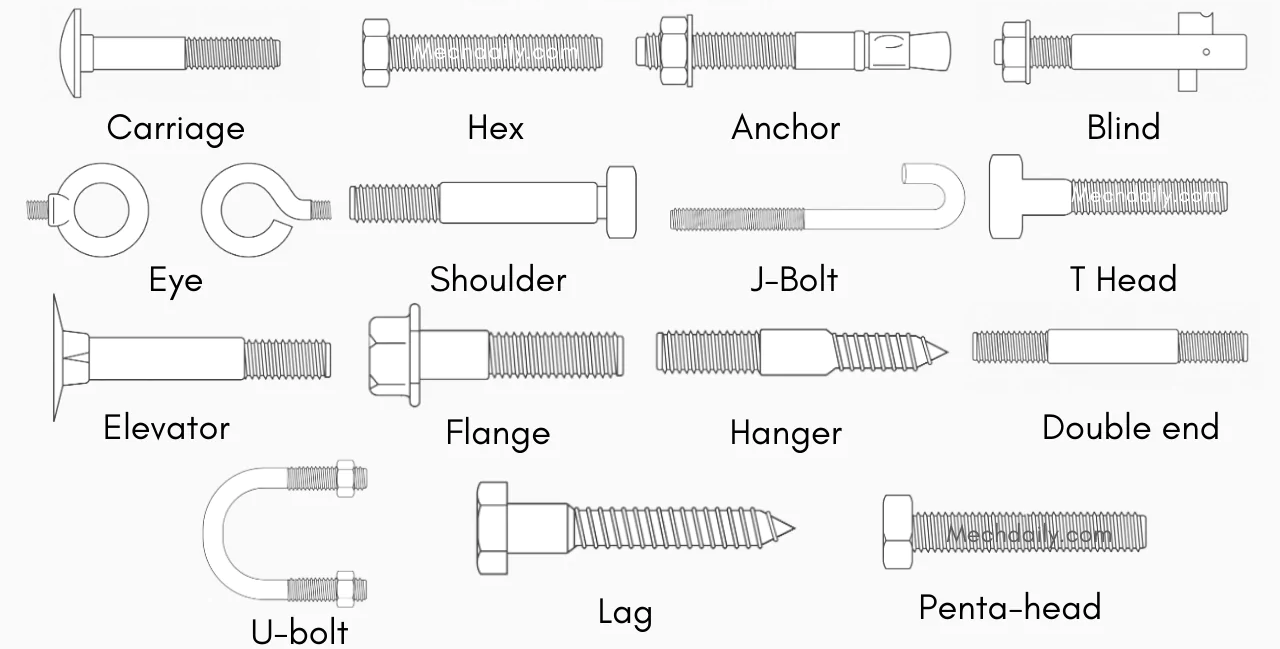

Common Types of Bolts

Like nuts, bolts are available in a wide range of types to suit different materials, load conditions, and installation environments.

Image: Types of Bolts

Hex Bolt

Hex bolts have a six-sided head and are commonly used in construction, machinery, and structural connections. They provide a strong clamping force and can be partially or fully threaded. Hex bolts are installed with a wrench or socket, offering excellent grip and torque control.

Carriage Bolt

Carriage bolts feature a smooth, rounded head with a square neck just below it. The square section locks into wood or metal to prevent the bolt from turning during tightening. These bolts are ideal for wood applications where a clean, finished appearance is desired on one side.

Anchor Bolt

Anchor bolts are used to attach structural elements to concrete or masonry surfaces. One end is embedded in the concrete, while the threaded end is used to fasten steel plates, columns, or equipment. They offer high load-bearing capacity and are essential in building foundations and heavy industrial setups.

Materials of Nuts and Bolts

Nuts and bolts are manufactured from a variety of materials to meet different performance, strength, and environmental requirements.

Stainless Steel

Stainless steel is known for its excellent corrosion resistance and long-term durability. It’s commonly used in outdoor, marine, and food-grade ss applications where moisture and chemicals are a concern. While not as strong as some high-grade steels, it provides reliable performance in most general-purpose uses.

Carbon Steel

Carbon steel is one of the most widely used materials for nuts and bolts due to its strength and affordability. It’s available in low, medium, and high carbon variants, each offering different mechanical properties. However, carbon steel is prone to rust if not properly coated or plated.

Brass

Brass offers moderate strength and good corrosion resistance, especially in electrical and plumbing applications. Its non-magnetic and non-sparking properties make it ideal for specialized environments. Additionally, its golden appearance is valued for decorative uses.

Titanium

Titanium provides an exceptional strength-to-weight ratio, making it both strong and lightweight. It’s highly resistant to corrosion, even in saltwater or chemical-rich environments.

Titanium fasteners are commonly used in aerospace, marine, and medical industries where performance and longevity are critical. Despite its advantages, titanium is more expensive and harder to machine than other materials.

Nylon

Nylon nuts and bolts are lightweight, non-conductive, and resistant to corrosion and many chemicals. They are often used in electronics, light-duty mechanical assemblies, and non-load-bearing applications. While not suitable for high-stress environments, they’re ideal where insulation or reduced weight is a priority.

Bolt Grades and Coating Options

Beyond material type, bolts are classified by strength grades and enhanced with coatings to improve performance under specific conditions.

Bolt Grades

Bolt grades indicate tensile strength and are often stamped on the bolt head. For example:

- Grade 2 bolts are low-strength, suitable for light-duty applications.

- Grade 5 bolts offer medium strength and are commonly used in automotive settings.

- Grade 8 bolts provide high strength for heavy-duty industrial use.

- In metric systems, Class 8.8, 10.9, and 12.9 are typical, with higher numbers indicating greater tensile strength.

Choosing the correct grade is critical for load-bearing reliability and safety compliance.

Coating Options

Various coatings are applied to bolts to enhance corrosion resistance and durability. Such as:

- Zinc plating: It offers basic protection against moisture and is commonly used for indoor or mild outdoor environments.

- Hot-dip galvanizing: It provides a thicker, more durable layer suitable for structural and outdoor applications.

- Black oxide, phosphate, or PTFE (Teflon): serve specific functions like friction reduction, chemical resistance, or improved wear performance.

Selecting the right coating ensures bolts perform reliably under environmental and mechanical stress.

When to Use Bolts and Nuts?

Choosing the right fastener depends on several factors, including mechanical load, exposure to vibration, environmental conditions, and how often the assembly needs to be taken apart.

- Bolt-driven assemblies rely on the bolt to provide the structural strength, such as in mounting steel beams

- Nut-driven assemblies focus on the holding or locking function, often seen in pre-threaded components.

Construction

In construction, bolts and nuts are widely used to join steel beams, columns, and structural frames. High-strength bolts (like Grade 8 or Class 10.9) are often specified for load-bearing joints.

Nuts provide the essential locking function, especially in bolted connections that require long-term integrity. Weather-resistant materials and coatings are commonly used in outdoor or exposed environments.

Machinery

Machinery assemblies demand fasteners that can withstand high stress, repetitive motion, and vibration. Bolts provide the core structural connection between components like motors, housings, and frames.

Lock nuts or washers are often added to prevent loosening during operation. Maintenance-friendly designs frequently use nuts and bolts that allow for easy disassembly and part replacement.

Electronics

In electronic applications, fasteners are typically smaller and lighter, often made of nylon, brass, or stainless steel. Nuts and bolts are used to secure circuit boards, enclosures, and mounting brackets without causing electrical interference.

Here, precision and insulation are more important than high mechanical strength. Non-metallic options are preferred when conductivity or magnetic properties must be avoided.

How to Install Nuts and Bolts Properly?

Proper installation starts with selecting the right size and thread type for both the nut and bolt to ensure a secure fit. The bolt should pass cleanly through the aligned holes, and the nut should thread on smoothly without cross-threading.

Choosing the Right Size

Selecting the correct size for both the bolt and the nut is essential for safe and effective fastening. Key dimensions include diameter, length, and thread pitch:

- Diameter refers to the width of the threaded section and must match exactly between bolt and nut to ensure proper engagement.

- Length applies to the bolt and should allow full thread contact with the nut without excessive protrusion.

- Thread pitch, or the distance between threads, must also be identical to avoid cross-threading or loosening under load.

A properly matched size guarantees full strength, smooth assembly, and long-term performance of the joint.

Thread Type

Thread type includes thread pitch (spacing between threads) and thread form (the shape and profile).

- Coarse threads (UNC or metric coarse) are more durable and faster to assemble, making them suitable for softer materials or general-purpose use.

- Fine threads (UNF or metric fine) provide better strength in tension and are used in high-vibration or precision assemblies.

- The nut and bolt must share the same thread pitch and diameter; mixing types can result in poor engagement or thread stripping.

Maintenance Tips for Nuts and Bolts

Regular maintenance ensures that nuts and bolts continue to perform safely and effectively, especially in environments subject to vibration, weather, or mechanical stress.

- Inspection Frequency

Visually inspect fasteners during routine equipment checks or scheduled service intervals. Look for signs of corrosion, wear, deformation, or loosened connections. Any fastener showing thread damage or rust buildup should be replaced immediately.

- Re-tightening Guidelines

In high-vibration settings—such as engines or industrial machinery—nuts and bolts may loosen over time. Use a torque wrench to verify tightness against the original specifications. Avoid over-tightening, which can lead to thread stripping or fatigue failure.

- Cleaning and Lubrication

If exposed to dirt, moisture, or chemicals, fasteners should be cleaned regularly to prevent seizing or corrosion. Apply anti-seize or thread lubricant as needed, especially for bolts installed in aluminum or high-temperature environments. Stainless steel and coated bolts may require less maintenance but should still be monitored.

Common Causes of Fastener Failure

Even well-installed nuts and bolts can fail over time if they’re not properly selected, maintained, or protected from environmental stress. Understanding the most common causes of failure helps prevent accidents, equipment damage, and unexpected downtime.

- Over-Tightening: Applying too much torque can stretch or strip threads, weaken the fastener, and reduce load-bearing capacity. This is especially risky for smaller-diameter or low-grade bolts.

- Under-Tightening: Insufficient torque may cause nuts to loosen under vibration or movement, leading to joint separation or wear. Always follow torque specifications appropriate to the material and fastener grade.

- Thread Stripping: Using mismatched thread sizes or forcing the nut onto damaged threads can lead to poor engagement and eventual failure. Cross-threading is a frequent cause during improper installation.

- Corrosion: Exposure to moisture, chemicals, or salt can degrade metal fasteners over time. Rust weakens structural integrity and makes removal difficult. Using stainless steel or coated fasteners helps reduce this risk.

- Fatigue Failure: Repeated load cycles can cause micro-cracks in fasteners, eventually leading to breakage. High-stress or dynamic environments require high-strength, fatigue-resistant materials.

- Vibration Loosening: In vibrating assemblies, nuts can back off over time if not properly locked in place. Solutions include using lock nuts, thread-locking compounds, or spring washers.

Conclusion

Nuts and bolts are fundamental fasteners that serve distinct yet complementary roles in securing assemblies. Proper selection, installation, and maintenance of nuts and bolts are key to achieving safe and reliable connections.

Xmake provides the best online CNC service and 3D printing solutions with no minimum order and instant online quotes for precision manufacturing. Get your quote today at xmake.com!