Choosing the right CNC machine is crucial; it affects production speed, material efficiency, and ultimately, your bottom line. In this guide, we’ll explore what a CNC machine is, the different types of CNC machines, their ideal applications, and how to choose the right CNC machine for your needs.

The following are the most widely used types of CNC machines:

- CNC Milling Machine

- CNC Lathe

- CNC Router

- CNC Plasma Cutter

- CNC Laser Cutter

- CNC Drilling Machine

- CNC Grinder

- CNC Waterjet Cutter

- Electrical Discharge Machine

- Pick and Place Machine

- Multi-Axis CNC Machine

- CNC Punching Machine

- 3D Printer

What is a CNC Machine?

A CNC (Computer Numerical Control) machine is a concept, device, or system that uses computer controls to execute a pre-programmed sequence that tells the tools to cut, shape, or finish materials like metal, plastic, or wood.

Unlike manual machining, CNC systems replace human intervention with precise automation, enabling high repeatability and accuracy. This level of control is especially critical in industries like automotive, aerospace, and electronics.

CNC machines operate using G-code, a standardized programming language that dictates tool movement (e.g., G0 to G92), spindle speed, feed rate (F values), tool changes (T codes), and dwell times (pause durations).

These instructions are usually generated through CAM software, which processes 3D CAD models and converts them into optimized toolpaths. This automation reduces manual programming errors and enhances productivity across various machining tasks.

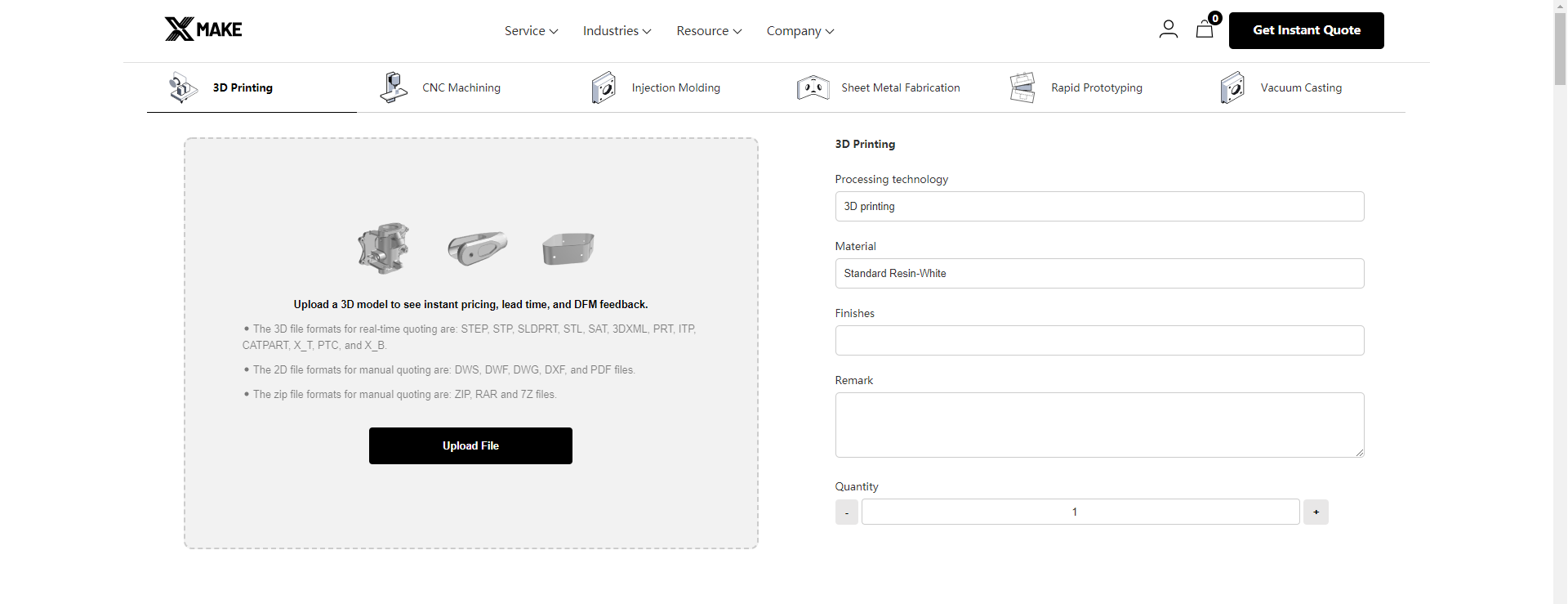

CNC Milling Machine

Image: cnc milling machine

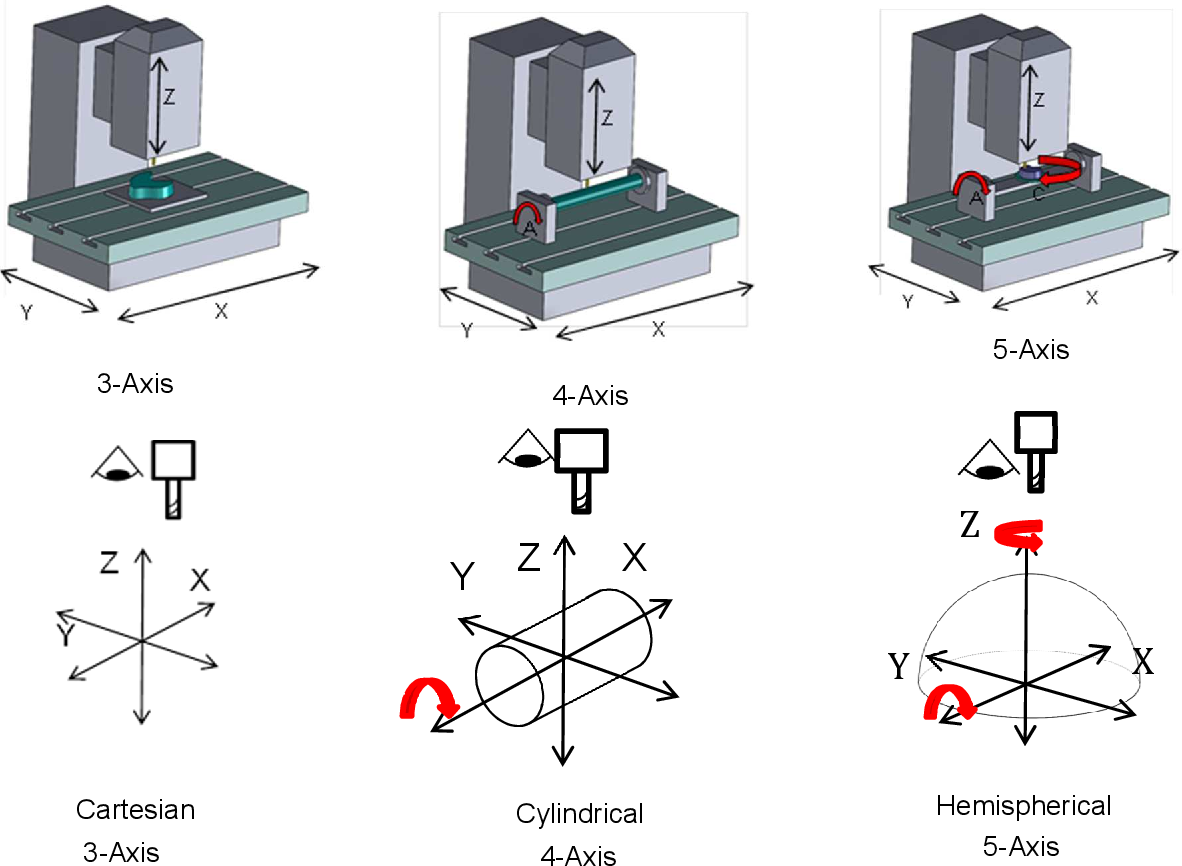

CNC milling machines utilize rotary cutting tools to machine custom shapes or parts out of a solid workpiece. They are typically classified as 3-axis to 5-axis machines, depending on the number of directions in which the tool or workpiece can move.

CNC milling machines can create complex parts such as gears, engine components, and other intricately shaped parts. They are capable of machining a wide range of materials, including but not limited to metals, plastics, and composites.

These machines are commonly used in both research and development or prototyping, as well as in high-volume production environments. Advanced 5-axis CNC milling machines handle complex geometries (e.g., turbine blades) by rotating and tilting the workpiece along multiple planes.

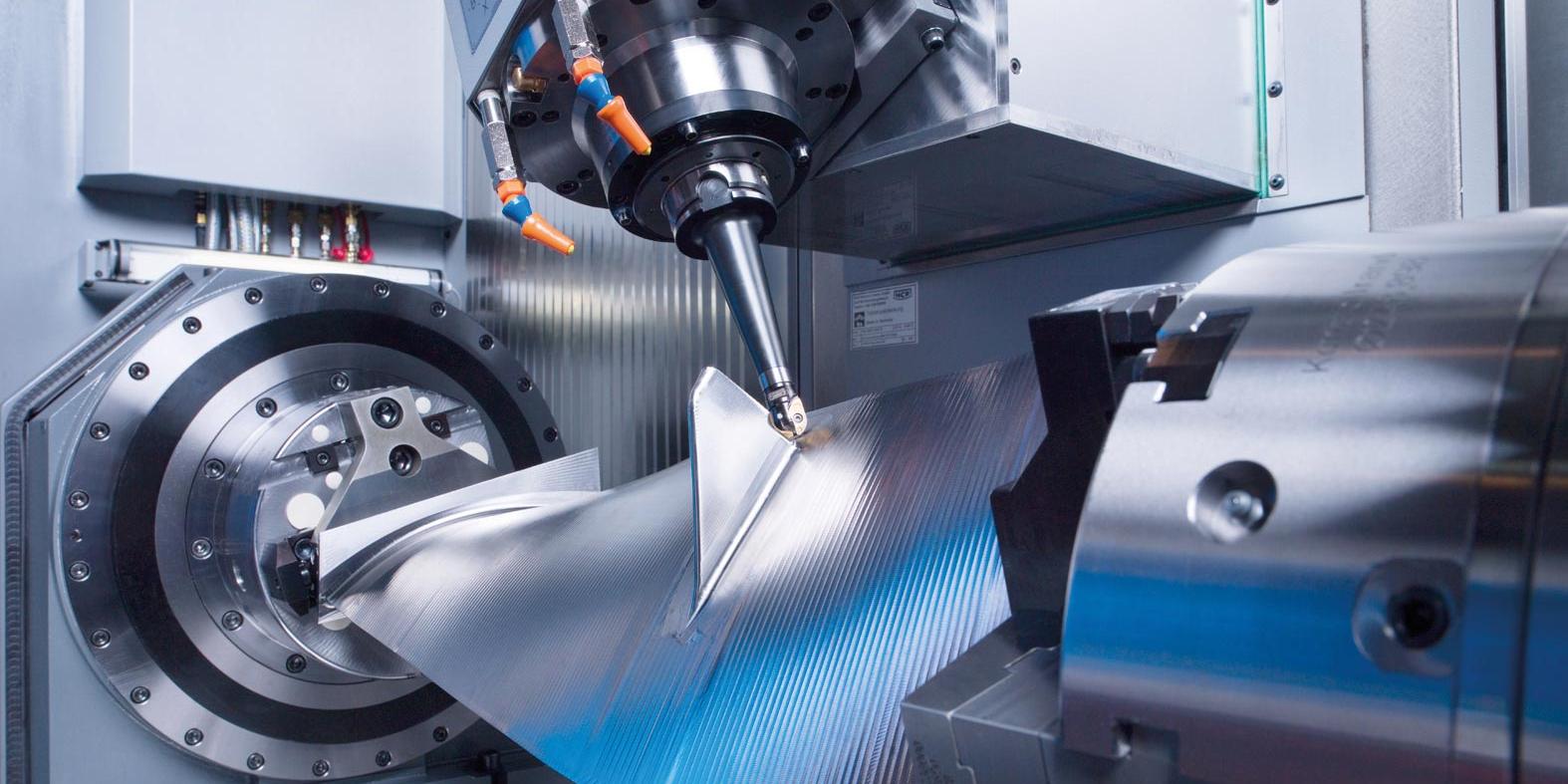

CNC Lathe

Image: cnc lathe

CNC lathes rotate the workpiece against stationary cutting tools to produce primarily cylindrical shapes, although other geometries are possible with advanced configurations.

They are widely used in high-volume production of parts such as screws, bushings, and shafts. By automating the turning process, CNC lathes reduce the time, inconsistency, and labor associated with manual machining.

Additionally, they help minimize human error, particularly when producing large quantities of identical components. CNC lathes are ideal for manufacturing symmetrical parts with precise dimensions and smooth surface finishes.

CNC Router

Image: cnc router

CNC routers are designed to cut softer materials such as wood, plastic, foam, and non-ferrous metals. They are widely used in cabinet making, sign production, and woodworking shops due to their speed, versatility, and cost-effectiveness.

Although less robust than industrial CNC mills, routers excel in rapidly removing material across large surface areas. They are ideal for creating decorative panels, furniture parts, and architectural features where high throughput and smooth finishes are important.

CNC Plasma Cutter

Image: cnc plasma cutter

CNC plasma cutters use a high-velocity jet of ionized gas (plasma) to rapidly cut through electrically conductive metals such as steel, stainless steel, and aluminum. This method is known for its speed, efficiency, and suitability for handling thicker materials.

Plasma cutting is commonly used in metal fabrication, construction, and automotive repair to produce structural components and large metal parts. It excels in high-speed cutting of thick sheet metal where ultra-fine precision is not required.

However, plasma cutters do not match the edge quality and accuracy of CNC laser cutters, making them less suitable for applications that require intricate detailing or tight tolerances.

CNC Laser Cutter

Image: cnc laser cutter

CNC laser cutting machines use focused laser beams, for example, CO₂, Fiber, Nd:YAG or diode lasers to melt, burn, or vaporize material. They produce clean, precise edges in metals, acrylics, and textiles, making them ideal for intricate designs in jewelry, electronics, and fine engraving.

Laser cutters are highly accurate and cause minimal material distortion, especially on thin materials. However, they are less effective when cutting reflective metals such as copper or brass, which can scatter the laser and reduce cutting performance.

CNC Drilling Machine

CNC drilling machines are used to create precise holes in finished parts such as metal plates, circuit boards, or castings. Drilling is often the final machining step to ensure accurate hole placement and consistent depth.

This precision is essential in applications like engine block manufacturing or electronic component production. Many CNC drilling machines feature multi-spindle heads, enabling them to drill multiple holes simultaneously in a single pass for improved efficiency.

CNC Grinder

CNC grinding machines are essential for achieving micron-level surface finishes and maintaining consistent quality. They use abrasive wheels to remove material with high precision, making them ideal for polishing and surface refinement.

These machines are widely used to process components such as automotive bearings and medical implants. CNC grinding also enables the machining of hardened metals that traditional cutting tools cannot handle effectively.

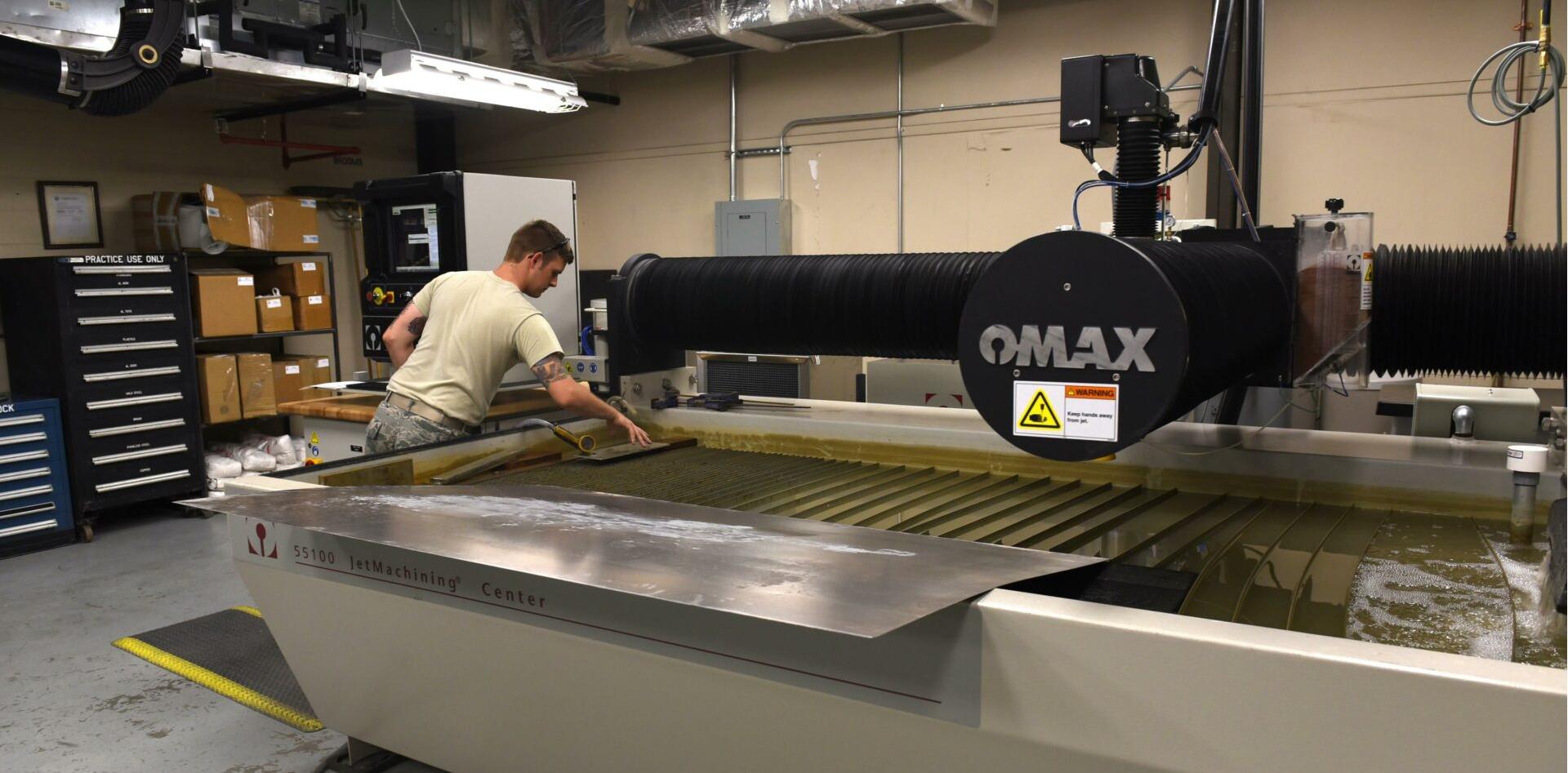

CNC Waterjet Cutter

Image: cnc waterjet cutter

A CNC waterjet cutting machine uses a high-pressure stream of water, often combined with abrasive particles, to cut a wide range of materials, including stone, glass, composites, and metals like titanium. Unlike thermal processes, a waterjet cutter produces no heat distortion, preserving the structural integrity of sensitive materials.

CNC waterjet cutting is ideal for thick or layered materials and is frequently used in aerospace and architectural industries, where precision and clean edges are critical for high-performance or decorative components.

Electrical Discharge Machine

A CNC Electrical Discharge Machine (EDM) uses precisely controlled electrical sparks to erode material from a workpiece, making it ideal for shaping hard metals like tungsten or carbide. Since the cutting tool does not physically touch the material, there is no mechanical wear, allowing for intricate and high-tolerance machining of dies, molds, or components with complex cavities.

CNC EDM Machine is widely used in the tooling and aerospace industries, particularly for forming parts that would be difficult or impossible to cut using conventional methods.

Pick and Place Machine

A pick and place machine is a specialized automation tool designed to precisely pick up components like surface-mounted electronic parts and place them accurately onto printed circuit boards (PCBs). These machines use robotic arms guided by programmed coordinates and vision systems to ensure high placement speed and accuracy.

Commonly used in electronics manufacturing, CNC Pick and Place Machines are essential for high-volume PCB assembly, improving efficiency and reducing manual labor. Their ability to rapidly handle small and delicate parts makes them indispensable in modern electronics production lines.

Multi-Axis CNC Machine

Image: multi-axis cnc machine

Multi-axis CNC machines, such as 5-axis systems, enable simultaneous movement along multiple planes, allowing for the production of highly complex geometries with exceptional precision. These machines eliminate the need to manually reposition workpieces, significantly improving machining efficiency and reducing scrap rates.

Multi-axis machining is essential for producing intricate parts like impellers, prosthetic joints, and aerospace components. Their ability to maintain tight tolerances across complex surfaces makes them indispensable in industries that demand both speed and precision, such as medical, aerospace, and advanced manufacturing.

CNC Punching Machine

CNC Punching Machines use computer-controlled rams and tooling to punch precise holes or shapes into sheet metal materials. Ideal for high-speed fabrication of panels, enclosures, and brackets, these machines can perform forming, embossing, and perforating operations with high repeatability. CNC punching is widely used in industries like electrical, HVAC, and metal fabrication, where consistent accuracy and speed are required.

3D Printer (Additive CNC Machine)

While not traditionally categorized alongside subtractive tools like mills or lathes, 3D printers are technically CNC machines; they follow digital instructions (G-code) to move along precise axes. Unlike conventional CNC equipment, which removes material to shape a part, 3D printers add material layer by layer, making them part of the additive manufacturing category.

3D printers are especially valued in rapid prototyping, product development, and complex geometric designs. They excel in producing intricate parts using materials like PLA, ABS, resin, or even metal powders in industrial-grade systems.

Although not suited for high-volume metal part production or structural applications, their low cost, design flexibility, and minimal waste make them a strategic tool in early-stage design and small-batch manufacturing.

Choosing an Online CNC Service

Types of CNC Machines

A reliable CNC machining service should offer a broad range of CNC machine types, such as milling, turning, laser cutting, waterjet, and EDM. Each machine type is designed for specific geometries and tolerances, so ensure the provider has the right equipment for your part complexity.

Materials

The ability to work with your specified material: aluminum, steel, titanium, plastics, or composites, is fundamental. Reputable services should offer guidance on material selection based on mechanical properties, finish, and end-use. Ensure the facility can handle both standard and specialty materials with proper certification and traceability when required.

Tolerances

Different industries demand different levels of accuracy. For aerospace, medical, or automotive applications, check that the service can consistently meet cnc tolerances (e.g., ±0.005 mm). Ask for sample reports, quality certifications (ISO 9001, AS9100).

Turnaround Time

Lead time varies between prototyping and full-scale production. Confirm that the CNC provider can meet your project schedule, whether you need a single unit or thousands. Some services specialize in rapid prototyping, while others are optimized for long-term, high-volume production with streamlined workflows.

Pricing

CNC machining costs are influenced by material, complexity, quantity, finishing, and delivery speed. Look for services that offer instant quoting tools or detailed breakdowns in their estimates. Transparent pricing helps you compare providers and manage budgets effectively without unexpected cost escalation.

Post-Processing

An ideal machining service should provide in-house or partnered post-processing options, including anodizing, powder coating, polishing, or heat treatment. Integrated finishing services save time and ensure consistent quality from raw machining to final delivery.

Technical Support

Effective communication and engineering support are crucial, especially for complex parts. Choose a partner who can review your CAD files, suggest design for manufacturability (DFM) improvements, and respond promptly to technical inquiries. The ability to collaborate closely can reduce rework and accelerate project timelines.

Conclusion

Understanding the various types of CNC machines helps you choose the right solution for your manufacturing needs. If you’re looking for a flexible and efficient partner, Xmake offers professional CNC services with instant online quotes, no minimum order requirements, and global delivery.