When it comes to materials, the terms resin and plastic are often used interchangeably. In fact, you’ll find products, like fountain pens, decorative items, or even electronic housings, marketed as being made of “resin” when they could just as easily be described as plastic.

While these two materials are closely related, they are not identical. Understanding the distinction between them can help you choose the right material for your specific needs in manufacturing, design, or everyday applications.

1. What Is Resin?

Resin refers to a broad group of solid or highly viscous substances that can be either naturally occurring or synthetically produced.

- Natural resins come from plants, such as tree sap or pine resin, and have been used for centuries in varnishes, adhesives, and even incense.

- Synthetic resins are man-made materials that mimic or improve on these properties. They serve as the raw feedstock for creating plastics and other polymers.

Examples include epoxy resins, which are valued for their strong bonding and chemical resistance, and polyurethane resins, which are used in coatings, foams, and adhesives. In many industrial settings, when people talk about “resin,” they usually mean these synthetic types.

In short, resins are typically the starting material, a pre-polymer substance that can be cured, hardened, or polymerized into more durable forms.

2. What Is Plastic?

Plastic is a broad category of synthetic materials derived from polymers, usually produced by processing resins. Unlike raw resins, plastics are fully formed materials ready for end-use.

Plastics are divided into two main categories:

- Thermoplastics: These can be melted, reshaped, and solidified repeatedly. Examples include polyethylene (PE), polypropylene (PP), and polylactic acid (PLA), which is commonly used in 3D printing.

- Thermosetting plastics: These undergo a curing process and, once hardened, cannot be melted and reshaped. Epoxy plastics and phenolic plastics are common examples.

Because of their versatility, plastics are used everywhere, from packaging and consumer goods to construction materials, electronics, and medical devices.

3. Difference Between Resin and Plastic

While resins and plastics are related, they differ in several important ways.

Material State

- Resin

Typically in a liquid or semi-solid form before curing. It can be natural (like tree sap) or synthetic (like epoxy or polyurethane). Resins are essentially pre-polymers – substances that will chemically harden into a solid form through a curing or polymerization process.

- Plastic

A finished solid material, already polymerized and processed for end-use. Plastics can be thermosetting (permanently hard) or thermoplastic (re-moldable with heat).

Role in Manufacturing

- Resin as a Raw Material

Resin often serves as the starting point in making plastics or composites. For example, epoxy resin can be used in coatings, adhesives, or combined with fibers to create composite plastics.

- Plastic as a Product

Plastic is a ready-to-use material for molding, extrusion, or 3D printing. It’s what you actually find in bottles, toys, electronics, or automotive parts.

Processing

- Resin Processing

Requires curing, a chemical reaction (like polymerization or cross-linking) that hardens the material. Some resins must be mixed with hardeners, catalysts, or fillers. Once cured, many resins become brittle and cannot be reshaped.

- Plastic Processing

Plastics, especially thermoplastics, can be heated, melted, and reshaped multiple times. They are compatible with large-scale methods like injection molding, extrusion, or blow molding, making them highly versatile for mass production.

Appearance

- Resin

Offers high precision, smooth surface finish, and specialty properties like chemical resistance or electrical insulation. However, it tends to be brittle and less impact-resistant.

- Plastic

Prioritizes durability, toughness, and flexibility. While surface detail may be less refined, plastics can withstand repeated mechanical stress and are generally easier to recycle.

Marketing

Resin is sometimes marketed as “premium” due to its clarity, smooth finish, or association with luxury products (e.g., high-end fountain pens).

Plastic, though more common and utilitarian, includes a wide range of engineering plastics that can rival resin in performance but are often seen as everyday materials.

All plastics are made from resins, but not all resins become plastics. Resins are the precursor materials valued for specialty properties, while plastics are the finished products optimized for durability, versatility, and large-scale use.

4. Resin and Plastic Applications

Both resin and plastic are widely used, but in different contexts.

Resin Applications

- 3D Printing (SLA/DLP)

Resin is one of the materias for stereolithography (SLA) and digital light processing (DLP) 3D printers.

Its liquid form allows for extremely fine detail, smooth surfaces, and thin layers that can reproduce intricate designs, ideal for dental molds, miniatures, or jewelry prototypes. However, resin-printed parts are often more brittle compared to plastic prints, making them better suited for display or precision components rather than heavy-duty use.

- Adhesives and Coatings

Epoxy and polyurethane resins are widely used as strong adhesives, capable of bonding metals, ceramics, and composites. As coatings, they offer excellent resistance to chemicals, heat, and moisture, making them essential in industrial flooring, marine equipment, and electronics.

- Decorative Arts

Casting resin can be poured into molds to create clear, glass-like pieces or colored designs. Artists use it to embed flowers, pigments, or even objects inside the resin, producing unique decorative items and fashion accessories.

- Electronics and Aerospace

Resin compounds are applied in potting and encapsulation, protecting delicate circuits from vibration, dust, or moisture.

In aerospace and automotive composites, resin serves as the binder for carbon fiber or fiberglass, creating strong yet lightweight materials.

Image: a piece of resin product

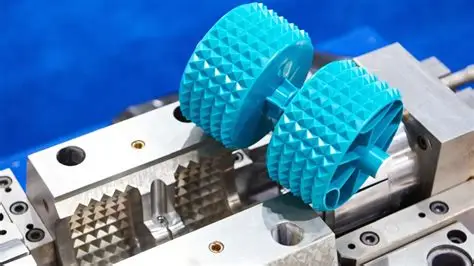

Plastic Applications

- Packaging

Plastics such as PET and HDPE are central to food and beverage containers, films, and protective wraps. Their light weight, transparency, and low cost make them indispensable in consumer packaging.

- Consumer Goods

Everyday products, storage bins, toys, kitchen utensils, phone cases, are almost always plastic. Plastics offer a balance of durability, flexibility, and affordability that resin alone cannot match.

- Automotive and Construction

In cars, plastics replace heavier metals in dashboards, bumpers, fuel tanks, and interior trims, improving fuel efficiency.

In construction, PVC pipes, insulation foams, and window frames highlight how plastics provide both cost-effectiveness and resilience.

- 3D Printing (FDM/SLS)

Thermoplastics like PLA, ABS, and nylon dominate filament-based printing (FDM) and powder-based printing (SLS).

These materials are inexpensive, tough, and well-suited for functional prototypes, tooling, or even end-use parts.

While resin often appears in specialized, high-precision contexts, plastic dominates large-scale manufacturing and everyday consumer products.

Image: a piece of plastic product

5. Pros and Cons of Resin vs Plastic

Both resin and plastic have unique advantages and drawbacks:

| Feature | Resin | Plastic |

| Appearance / Finish | Smooth, glossy, premium look | Can be less refined, surface may show layering in 3D prints |

| Detail / Precision | Excellent for fine detail and small parts | Lower precision for intricate designs |

| Durability | Brittle, less impact-resistant | Tough, flexible, handles mechanical stress well |

| Processing | Requires curing or chemical hardening | Can be molded, melted, reshaped (thermoplastics) |

| Cost | Usually higher | More cost-effective for mass production |

| Recyclability | Difficult to recycle | Many common plastics (thermoplastics) are recyclable, but not all types |

| Common Applications | 3D printing (SLA/DLP), adhesives, coatings, jewelry | Packaging, consumer goods, automotive, functional 3D prints |

In practice, the choice depends on what you need: resin for specialty, high-detail, or adhesive purposes, and plastic for durable, cost-effective, large-scale solutions.

Which One to Choose?

Both resin and plastic have their place, but the choice depends on your priorities and the context of use.

When to Choose Resin?

Resin is ideal when you need fine detail, premium aesthetics, or specialized performance. It excels in 3D printing for intricate models, in adhesives where strong bonding is required, or in decorative applications where clarity and smoothness are valued.

Resin is also the go-to for electronics encapsulation and composite materials in aerospace or automotive industries, where the strength-to-weight ratio matters more than cost.

When to Choose Plastic?

Plastic is the better option when durability, scalability, and affordability are the main concerns. For packaging, consumer goods, automotive parts, or functional prototypes, plastics offer toughness, flexibility, and cost-effectiveness. They are also easier to recycle and more practical for mass production, making them the dominant choice for everyday products.

Resin delivers precision and specialty qualities, while plastic provides resilience and economic efficiency. The decision comes down to whether your project values performance in detail or practicality in scale.

Conclusion

Although resin and plastic are closely connected, one being the precursor to the other, they are not the same thing. Resin often emphasizes precision, bonding strength, and specialty applications, while plastic provides durability, scalability, and cost-effectiveness.

Xmake provides the best 3d printing online solutions with no minimum order and instant online quotes for precision manufacturing. Get your quote today at xmake.com!

FAQs

1. Is Resin Plastic?

Not exactly. Resin is the raw or precursor material used to make some types of plastics, but it is not fully processed plastic itself. All plastics are made from resins, but not all resins become plastic.

2. Which Is Stronger: Resin or Plastic?

Plastic is generally stronger and more impact-resistant, especially thermoplastics. Resin can be very strong in certain applications, but it is often more brittle and suited for precision or decorative purposes rather than heavy-duty use.

3. Can You 3D Print With Both Resin and Plastic?

Yes, but the technologies differ. Resin is used in SLA/DLP 3D printers for high-detail prints, while thermoplastics like PLA or ABS are used in FDM printers for durable, functional parts.

4. When Should I Choose Resin Over Plastic?

Choose resin when you need fine detail, smooth finishes, or specialty properties such as chemical resistance, electrical insulation, or decorative clarity.