You see anodized aluminum everywhere: smartphones, kitchen appliances, automotive parts, and architectural elements. But what is it?

Unlike paint or plating, which just sit on top of the metal, anodizing changes aluminum’s surface through electrochemistry. This method creates a thick oxide layer that is corrosion and scratch-resistant, fade-resistant, and capable of vibrant coloration.

If you’ve had a peeling finish or corrosion of parts, you would come to know that anodized aluminium is the gold standard in permanent protection. Keep reading!

What is Aluminum Anodizing?

Aluminum anodizing is an electrochemical process that enhances the natural oxide layer on aluminum surfaces to improve corrosion resistance, durability, and aesthetic appearance.

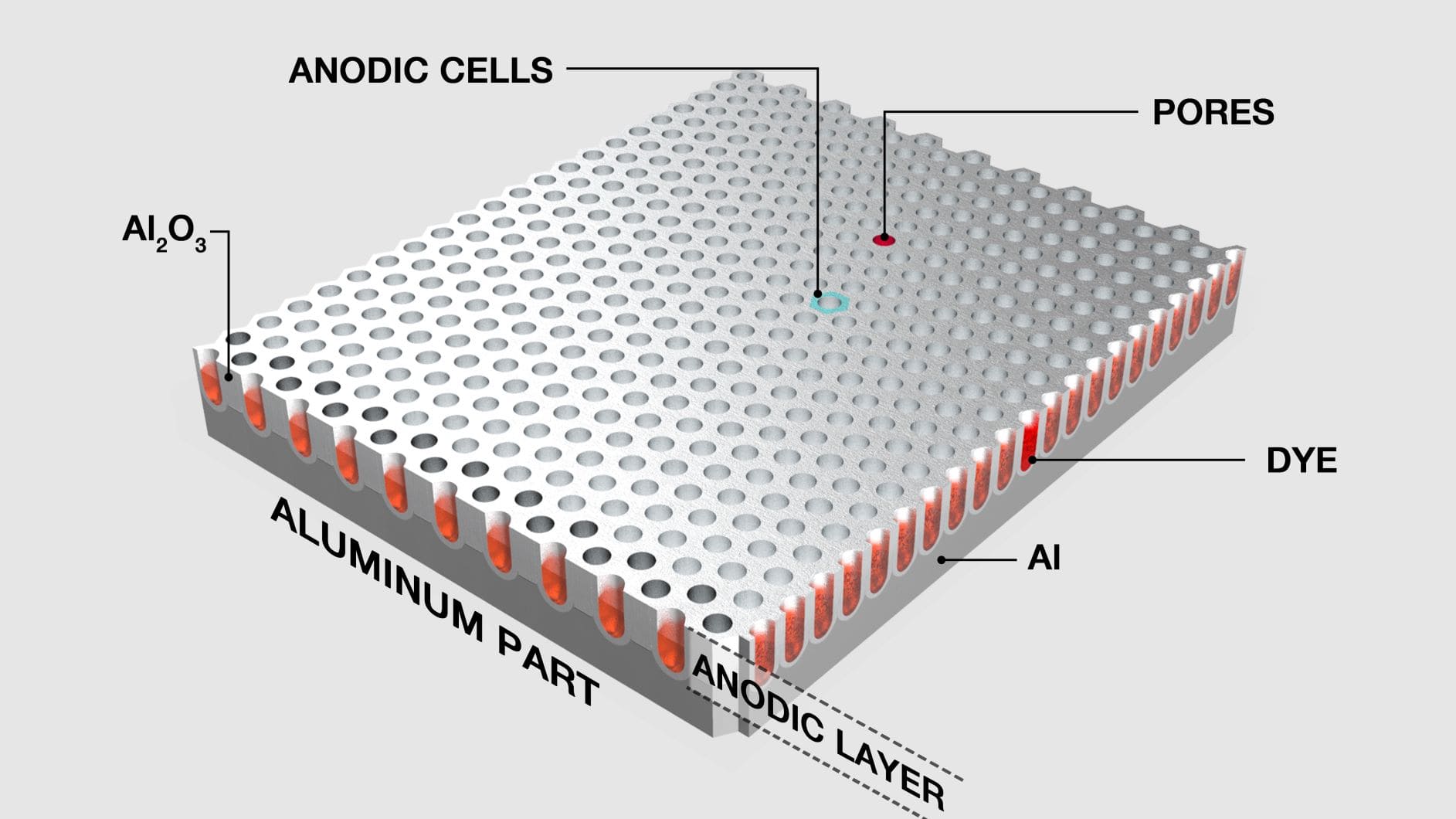

The Electrochemical Process

Aluminum anodizing uses controlled chemistry and electricity. Initially, a voltage is applied while aluminum sits in a sulfuric or chromic acid bath.

The aluminum part is connected as the anode, and when current flows, oxygen ions from the electrolyte combine with aluminum atoms at the surface to form a thickened aluminum oxide layer. This oxide layer is porous at the microscopic level, as some aluminum dissolves in the electrolyte during formation, creating uniform nanopores.

The layer is typically harder and more wear-resistant than raw aluminum, up to about 30% harder than mild steel. In the final sealing stage, these pores are closed (often by hydration in boiling deionized water or nickel acetate), locking in dyes if applied and enhancing corrosion resistance.

Why Not Other Metals, Like?

Aluminum’s unusual reaction makes it well-suited for this process. When a metal like steel rusts when oxidized, Aluminum immediately creates a thin natural oxide layer on exposure to air. However, this layer is fragile. Anodizing strengthens this property by using electrochemical process principles.

Aluminum transfers electricity well and does not corrode in acid for long enough to oxidize under control. Metals like copper dissolve in acid baths too quickly. As a result, aluminum is capable of growing an oxide layer that is much more precise than other metals, as it strikes a balance between conductivity and reactivity.

How Does Anodizing Process Work?

Now, let’s break down the anodizing process step by step. The aluminum parts are kept in an Acid electrolyte bath at different currents. This makes an oxide layer that is uniform and integrates with the base metal.

Step 1: Pre-Treatment Cleaning

Initially, aluminum undergoes rigorous cleaning. Cleaning of an oily residue and etching of a mill scale are both processes intended to improve adhesion through mechanical means. That will make sure the metal reacts evenly in the acid electrolyte bath. If this stage is missing, the contaminants will lead to uneven oxide layer growth or adhesion failures.

Step 2: Anodizing Bath Setup

The cleaned aluminum is placed in a sulfuric acid bath with an inert cathode, and a direct current (12–18 V, 68–72°F) is applied. Voltage and temperature control the oxide layer’s thickness and pore size, with lower temperatures yielding denser, more corrosion-resistant layers.

Step 3: Filling the Pores

After anodizing, the porous oxide surface is sealed—often in near-boiling water with nickel acetate—to hydrate the oxide and close the pores. This locks in dyes, blocks contaminants, and enhances durability in harsh environments. Aluminum can be anodized with two types of dye that each of which has its benefits.

Organic Dyes:

- Provide a wider range of colors, including vibrant and pastel shades.

- Use absorption to get through the oxide layer pores.

- Best suited for indoor applications with limited UV exposure.

- Consumer electronics means devices for daily use.

Inorganic Dyes (Electrolytic Coloring):

- Use metallic salts, such as tin and cobalt, to make darker shades that are more stable under ultraviolet light.

- These are deposited by electrical current to improve weather resistance.

- Most popular for architectural and automotive exteriors.

- Stadiums, wire ropes, and the like.

While organic dyes can provide different shades, inorganic dyes always have better performance in terms of long-term outdoor durability.

What Are the Types of Anodized Aluminum?

If you know the anodized aluminum type, you can choose the correct style for the right protection on your project.

Though all means produce protective oxide coatings, they differ from one another in thickness, durability, and applications. Types I, II, & III are the three main types of fabricated aluminum anodizing. Use any of them according to your needs.

Type I: Thin Coatings for Aerospace

Designed specifically for aerospace equipment, Type I uses chromic acid to generate the thinnest oxide layer at parts of 0.5-18 microns. This process provides good corrosion resistance and does not add much weight, which is important for an aircraft material.

It doesn’t take dyes very well, but it is good insulation because it is non-conductive. The military often specifies Type I for sensitive aerospace parts, where small dimensional changes are critical.

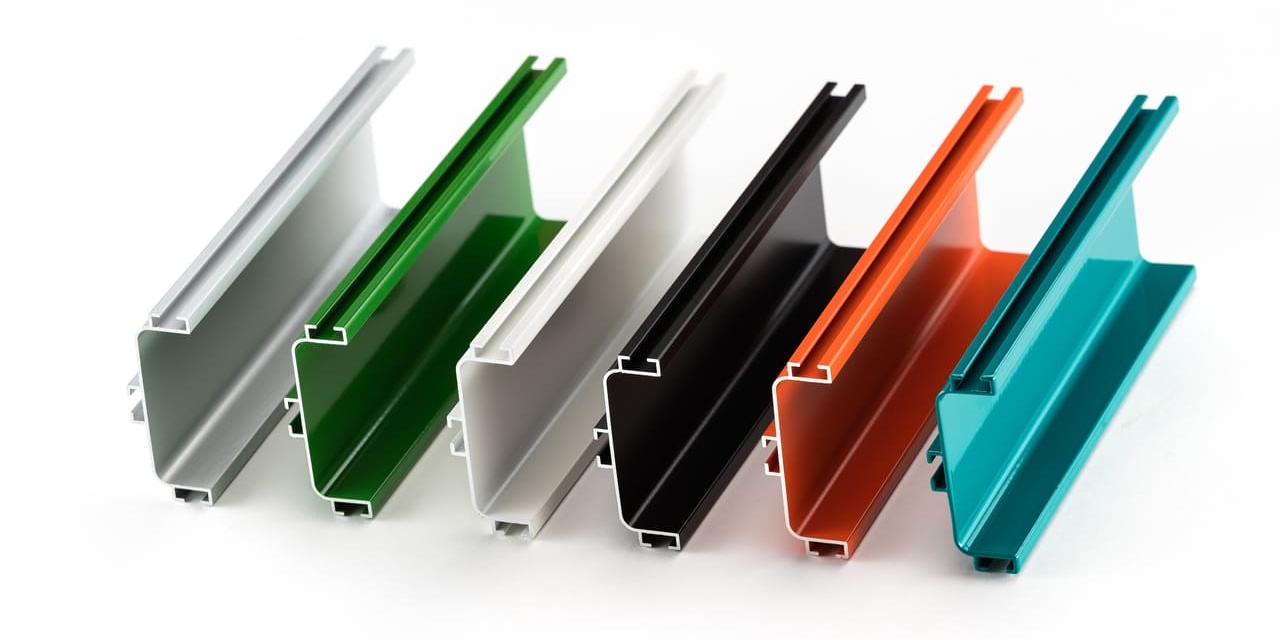

Type II: Color-Friendly Architectural Use

Type II anodizing is the most versatile of the options and uses sulfuric acid to create coatings measuring between 1.8-25 microns thick. What makes it widely used in architecture is that it readily accepts bright, UV-stable dyes.

Type II resists corrosion and makes the surface shiny. It is used in buildings, automobiles, and many other things. It is more cost-effective than Type II, I, which makes it the primary choice in most decorative and moderate-duty situations where color matters.

Type III: Industrial-Grade Wear Resistance

Type III (hardcoat) provides the thickest (13-150 microns) and hardest oxide layer when maximum durability is required. The use of the extended sulfuric acid process at low temperature results in a very dense, abrasion-resistant surface, which is perfect for almost any requirement looking for industrial-grade quality.

Hard coat is the only type that can endure severe mechanical wear and tear on hydraulic systems, military equipment, and heavy machinery. Even if not so friendly to colors, it has a high wear resistance and the longest service life.

What Are the Advantages of Anodized Aluminum?

Anodized aluminum is a superior material choice. It has advantages that are superior to conventional metal finishes. The anodizing procedure offers a permanent protection system that gets incorporated into the metal, unlike temporary coatings. Coating hardened steel provides three main benefits: they are corrosion resistant, have enhanced hardness, and are environmentally friendly.

Corrosion-Resistant

Anodized aluminum has better construction in comparison to other metals. A thick oxide layer is impermeable to moisture, salt spray, and chemicals. For instance, marine parts and the facades are coastal buildings that last for decades with no rusting or decaying. This electrochemical protection won’t peel away or flake off as paint does. Hence, it will perform for a long time.

Greater Hardness

The anodizing of aluminum increases the hardness of aluminum so that it attains a hardness of 60-70 on the Rockwell C scale, which is approximately the same as that of certain steels. This extra toughness prevents the steel from scratches, abrasion, and general wear and tear. This makes it great for high-traffic applications. Like elevator panels or industrial machinery. Unlike powder coat, which can get damaged easily, anodized surfaces can take a lot of abuse and yet look good.

Sustainability vs. Plating/Painting

Anodized aluminum is one of the greenest metal finishes. Rather than plating or painting, it doesn’t have any volatile organic compounds (VOCs) and creates little hazardous waste. The use of water-based solutions and an oxide layer is fully recyclable. Besides, its long lifespan means it doesn’t have to be replaced often, which reduces impact on the environment and makes it popular in the green building sector.

Where is Anodized Aluminum Used?

Lightweight, hard, and beautiful, anodized aluminum finds uses in many industries. Because of its strength and corrosion resistance, along with other properties, steel is used everywhere, right from tall buildings to mobile phones. The top 3 sectors – construction, automotive, and consumer electronics use it heavily.

Building Decoration and Architectural Structures

Image: Anodized Aluminum Colors Chart

Anodized aluminum is an innovative approach to modern architecture, literally. Because of its weather-resistant properties, it is an ideal component for curtain walls, window frames, and roofing systems for decades of sun, rain, and pollution.

Unlike painted metals that fade, anodized finishes don’t lose their colors. Many iconic buildings showcase anodized finishes, from the corporate towers to the façades of museums. The lightness of the material helps with ease of installation and reduces dead loads.

Car Components and Temperature Regulation Gadgets

Most car parts are produced using anodized aluminium nowadays. It’s suitable for trim pieces, grilles, and more, as its finish is scratch-resistant and fade-proof, lasting longer than paint. Inside the engine, heat sinks and components are made using the material’s thermal conductivity and resistance to corrosion. Electric vehicles need anodized components to shed battery heat and cut weight. These are critical for maximizing range and efficiency.

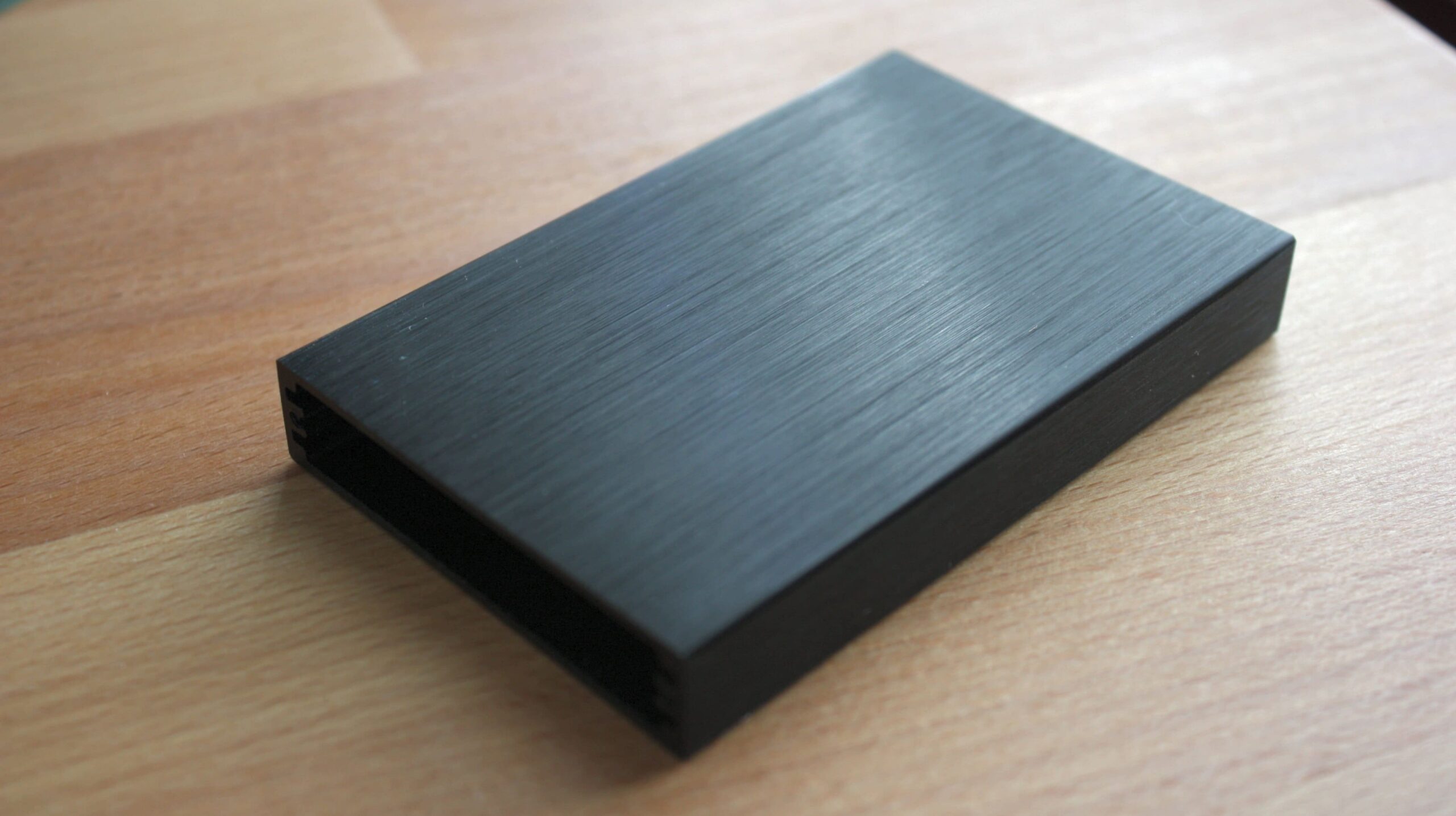

Consumer Electronics Casings

Your favorite gadgets likely utilize anodized aluminum for a reason. The process creates an ideal fusion of strength and beauty, which tech companies look for. These days, anodizing is used on numerous electronics, from laptop computers to smartwatches. This light and strong coating prevents wear and tear from everyday use.

Available in every color and shade imaginable, most importantly. An oxide layer that does not conduct electricity inhibits electrical interference. Thus, it is stylish yet practical.

How Durable is Anodized Aluminum?

Aluminum, which has been anodized, can stand up to most situations and last a long time. The electrochemical treatment creates a surface that is far more resistant to fading from UV radiation, scratching, and chemicals than painted or coated metal. Tests and applications have shown that anodized aluminium will last for thirty years or more in the real world.

Accelerated weathering test results:

A few months in the laboratory simulated decades in the field. In these laboratory tests, anodized aluminum specimens resist.

- Over 5,000 hours of UV exposure. Equivalent to receiving 25+ years of

Sunlight without any fading. - Over 1000 hours’ salt spray testing (ASTM B117) with no corrosion.

- Taber abrasion tests with greater than 10 times better than paint.

The molecular architecture of the oxide layer allows it to bind permanently to the base metal, instead of merely layering on top like paint. These typical points of failure for other finishes won’t catch your PMMYC.

Can you Color Anodized Aluminum?

Absolutely! Coating aluminum gives it beauty in color and a tough surface, which is used in anodization. The anodizing process uses a porous oxide layer that readily absorbs dyes before the layer is sealed. Due to this process, the color is vibrant, fade-resistant, and available in almost any colour.

If you’re looking for classic blacks for architectural trim or brighter colours for consumer electronics, anodising provides long-lasting colour integrity superior to that of paints and coatings.

Image: Anodizing Aluminum Black

What Are the Limitations of Anodized Aluminum?

Though anodized aluminum is very beneficial, it is not always the answer. The anodizing process has certain limitations that engineers and designers must consider. These limitations can be material, geometrical, and others. Knowing which boundaries to explore ensures the appropriate finish gets selected.

Size/shape restrictions in tanks:

Anodizing’s immersion process creates inherent size limitations.

- Tank dimensions dictate maximum part size (typically ≤ 20 ft for industrial setups)

- Complex geometries with deep recesses or hollow cavities may trap air or chemicals, causing uneven coating

- Thin-walled components (< 0.5mm) risk warping from thermal stress during processing

Cost factors for complex parts:

Precision anodizing carries hidden cost considerations.

- Racking complexity for unusual shapes adds labor (up to 3x standard pricing)

- Tighter tolerances demand more process checks (+15-25% cost)

- Color-matching small batches increases chemical waste expenses

Partnering with Xmake

Anodized aluminum combines lightweight strength with exceptional durability, offering corrosion, scratch, and UV resistance far beyond traditional coatings. Its wide color range and premium finish make it a top choice in aerospace, architecture, electronics, and automotive design.

If you’re looking for a custom anodizing solution for your project, let Xmake help with professional custom finishes. When you want to make high-performance parts or attractive architectural elements, our material innovation resources help you optimize aluminum.

FAQs

1. Is anodized aluminum good or bad?

Anodized aluminum is generally considered good because the process enhances durability, corrosion resistance, and appearance. However, its suitability depends on the application and environment.

2. What is the purpose of anodizing?

The primary purpose of anodizing is to create a protective oxide layer on aluminum that improves corrosion resistance, surface hardness, and allows for decorative finishes.

3. What are the disadvantages of anodizing?

While anodizing has many benefits, disadvantages include limited color choices compared to coatings, potential higher cost, and reduced effectiveness in extremely aggressive environments like saltwater exposure.