Stainless steel is a corrosion-resistant alloy of iron, chromium, and other elements, known for its durability, strength, and aesthetic appeal. Its ability to withstand harsh environments without rusting makes it an essential material across countless industries.

Within this broad family, austenitic stainless steel stands out as the most widely used type, prized for its superior corrosion resistance, formability, and versatility.

What is Austenitic Stainless Steel?

Stainless steel can be grouped into several main categories based on its microstructure and alloy composition:

- Austenitic – High chromium and nickel content, non-magnetic in the annealed state, excellent corrosion resistance.

- Ferritic – Magnetic, lower nickel content, good corrosion resistance but less formable.

- Martensitic – High strength and hardness, lower corrosion resistance, often used in cutlery and tools.

- Duplex – A mix of austenitic and ferritic structures, offering balanced strength and corrosion resistance.

Austenitic stainless steel is a type of stainless steel characterized by its face-centered cubic crystal structure, giving it exceptional corrosion resistance, toughness, and formability across a wide temperature range.

In metallurgy, “austenitic” refers to a face-centered cubic (FCC) crystal structure, which remains stable at all temperatures from cryogenic levels up to the melting point. This structure is achieved primarily through the addition of nickel, which stabilizes the austenitic phase, and chromium, which forms a passive oxide layer that protects against corrosion.

Below is a comparison of the main stainless steel categories:

|

Feature |

Austenitic |

Ferritic |

Martensitic |

Duplex |

|

Crystal Structure |

Face-centered cubic (FCC) |

Body-centered cubic (BCC) |

Body-centered tetragonal (BCT) |

Mix of FCC & BCC |

|

Key Alloying Elements |

High Cr (16–26%), Ni (6–22%), possible Mo, N |

Cr (10.5–30%), very low Ni |

Cr (11–18%), low Ni, higher C |

Cr (18–28%), Ni (4–7%), Mo, N |

|

Corrosion Resistance |

Excellent, even in harsh environments |

Good, especially against stress corrosion cracking |

Fair to good, lower than austenitic/ferritic |

Very good, superior to austenitic in chloride resistance |

|

Strength & Hardness |

Moderate strength, good toughness |

Moderate strength, less ductile |

High strength and hardness, lower toughness |

Higher strength than austenitic/ferritic |

|

Magnetic? |

Non-magnetic (annealed), may become slightly magnetic after cold working |

Magnetic |

Magnetic |

Slightly magnetic |

|

Common Applications |

Food processing equipment, chemical plants, marine fittings, architectural cladding |

Automotive exhaust systems, industrial equipment, architectural trim |

Cutlery, surgical instruments, turbine blades |

Offshore structures, chemical processing, pressure vessels |

Common Grades of Austenitic Stainless Steel

Austenitic stainless steels come in a variety of grades, each tailored to specific performance needs and environments. While all share the same austenitic crystal structure, their alloy compositions can vary significantly, influencing their corrosion resistance, strength, machinability, and cost.

|

Feature |

301 |

303 |

304 |

316 |

|

Key Alloying Elements |

Cr 16–18%, Ni 6–8% |

Cr 17–19%, Ni 8–10%, S ≤0.35% |

Cr 18–20%, Ni 8–10.5% |

Cr 16–18%, Ni 10–14%, Mo 2–3% |

|

Corrosion Resistance |

Good |

Good (slightly less than 304) |

Excellent |

Excellent (superior in chloride environments) |

|

Strength & Hardness |

High after cold working |

Moderate |

Moderate |

Moderate |

|

Formability & Weldability |

Good |

Excellent machinability, fair weldability |

Excellent |

Excellent |

|

Common Applications |

Springs, automotive trim, structural parts |

Precision parts, fasteners, gears |

Kitchenware, tanks, piping, architecture |

Marine fittings, chemical processing, pharma equipment |

301 Stainless Steel

Known for its excellent strength after cold working, 301 offers good corrosion resistance and high ductility. It’s often used in springs, automotive trim, and structural components requiring a combination of toughness and formability.

303 Stainless Steel

Designed for improved machinability, 303 contains added sulfur or selenium, making it ideal for complex machining jobs. It retains good corrosion resistance but is slightly less resistant than 304 due to the added sulfur.

304 Stainless Steel

The most widely used stainless steel grade, 304 ss offers a balance of excellent corrosion resistance, formability, and weldability. Common applications include kitchen equipment, tanks, piping, and architectural panels.

316 Stainless Steel

Enhanced with molybdenum, 316 offers superior resistance to chlorides and acidic environments, making it the go-to choice for marine applications, chemical processing, and pharmaceutical equipment.

Read more: 18/8, 316, and 304 Stainless Steel: What are Their Differences?

Key Properties of Austenitic Stainless Steel

Building on the common grades discussed above, austenitic stainless steels share a set of defining properties that make them the most popular stainless steel family in the world.

While exact performance varies by grade, the underlying austenitic crystal structure ensures consistent advantages across the category. Key properties include:

- Exceptional Corrosion Resistance

- High Toughness and Strength

- Non-Magnetic in Annealed Condition

- Excellent Formability and Weldability

- Good Heat Resistance

Applications of Austenitic Stainless Steel

Austenitic stainless steels are used in an exceptionally wide range of industries. Below are some of the most common application areas with examples.

Food Processing, Kitchen Equipment

Often referred to as food grade stainless steel, grades like 304 and 316 are widely used for food preparation surfaces, storage tanks, and kitchen appliances.

- Cookware

- Food preparation tables

- Brewing vessels

- Commercial sinks

- Dairy processing tanks

Chemical, Petrochemical

316 stainless steel, in particular, is common in chemical pipelines and offshore oil equipment exposed to harsh chemicals.

- Reactors

- Heat exchangers

- Chemical storage tanks

- Processing pipelines

Architecture, Construction

Austenitic grades combine durability with aesthetic appeal.

- Building facades

- Handrails

- Glass support fittings

- Interior decorative trim

Medical, Pharmaceutical Equipment

Non-reactive and easy to sterilize, austenitic stainless steels can withstand repeated cleaning and sterilization cycles, ensuring safety in sterile environments.

- Surgical instruments

- Autoclaves

- Hospital beds

- Pharmaceutical mixing tanks

Marine, Offshore Structures

316 stainless steel is a mainstay for boat fittings, propeller shafts, seawater piping, and offshore oil platforms due to its excellent resistance to saltwater corrosion. Even in splash zones and tidal areas, it maintains performance without rapid degradation.

Pros & Cons of Austenitic Stainless Steel

Austenitic stainless steels offer a balance of properties that make them highly versatile, but like any material, they come with certain limitations.

Advantages

- Excellent corrosion resistance – Protects against rust and chemical attack in diverse environments.

- High toughness – Maintains strength even at cryogenic or elevated temperatures.

- Non-magnetic (annealed) – Suitable for sensitive equipment and electronics.

- Good formability – Can be shaped into complex parts without cracking.

- Excellent weldability – Compatible with most conventional welding techniques.

- Heat resistance – Some grades retain mechanical properties at high temperatures.

Limitations

- Higher cost – Nickel content makes austenitic grades more expensive than ferritic or carbon steels.

- Lower wear resistance – Less suitable for abrasive or high-friction applications.

- Susceptible to stress corrosion cracking – Especially in chloride-rich environments under tensile stress.

- Work hardening – Cold working increases hardness but may induce slight magnetism and reduce ductility.

How Austenitic Stainless Steel is Manufactured?

The production of austenitic stainless steel involves a series of carefully controlled steps, each contributing to its final properties of corrosion resistance, strength, and surface quality.

1. Melting

Raw materials, including iron, scrap steel, and alloying elements like chromium and nickel, are melted together in an electric arc or induction furnace to form a homogeneous molten alloy. The precise combination of elements determines the grade and performance characteristics of the final steel.

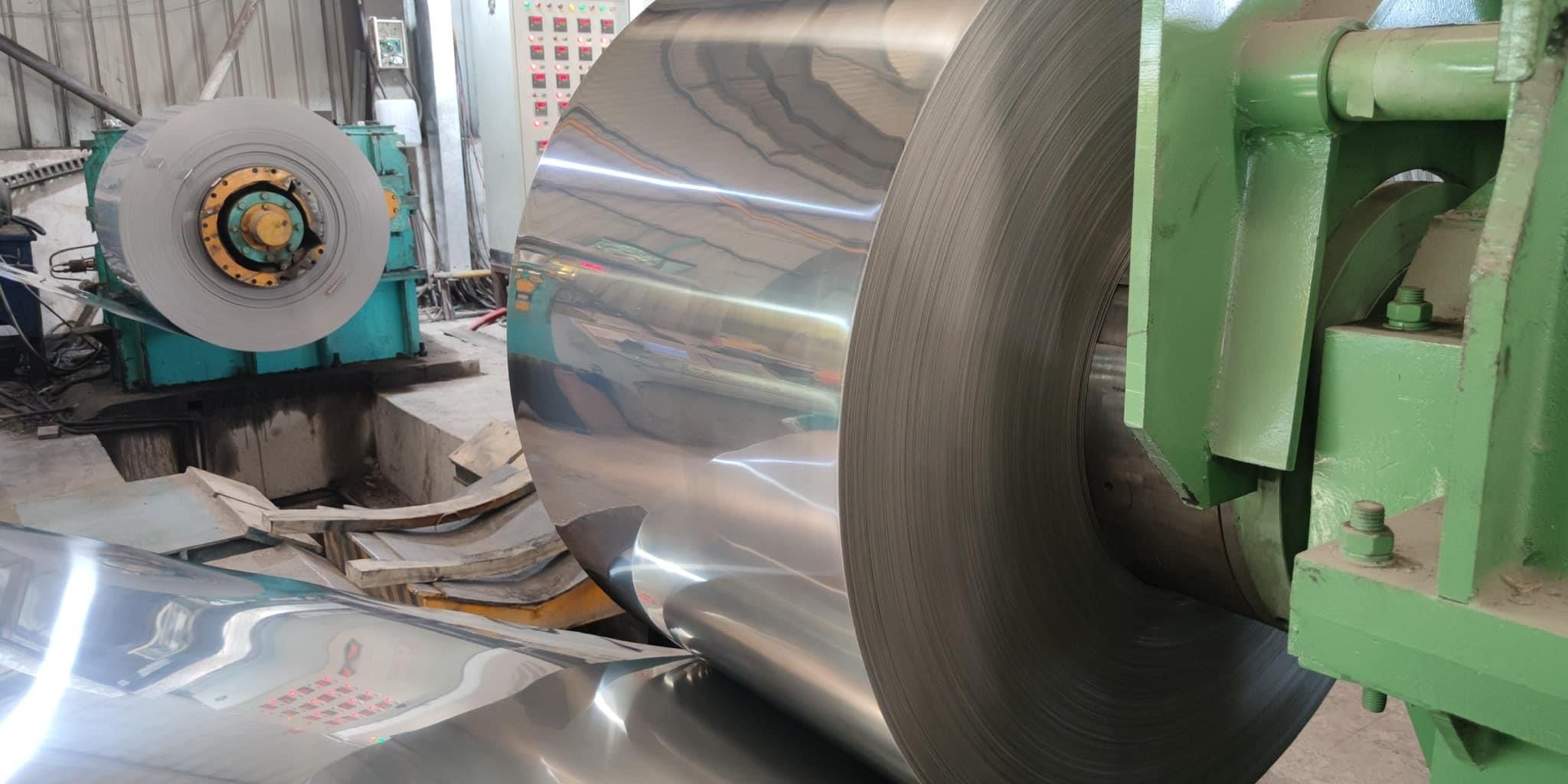

2. Hot & Cold Working

The molten steel is cast into slabs or billets and then processed through hot working techniques such as rolling or forging to shape it into sheets, plates, or bars. After cooling, cold working may be applied to further refine the dimensions, improve strength, and enhance surface finish.

3. Heat Treatment

Annealing involves heating the steel to a high temperature and then slowly cooling it to relieve internal stresses and restore ductility. Pickling is a chemical treatment, usually with acids, to remove scale, oxides, and impurities from the surface. Together, they ensure the steel has both optimal mechanical properties and a clean, corrosion-resistant surface.

4. Finishing Options

The final stage focuses on surface treatment to meet aesthetic or functional requirements. Common finishing options include:

- 2B finish – Smooth, matte surface for general use.

- BA (Bright Annealed) finish – Reflective, shiny surface ideal for decorative applications.

- Brushed finish – Textured linear pattern for visual appeal or slip resistance.

- Mirror finish – Highly polished, reflective surface for premium or architectural applications.

This combination of controlled alloying, mechanical processing, heat treatment, and finishing ensures that austenitic stainless steel achieves the optimal balance of mechanical performance, corrosion resistance, and appearance.

Maintenance of Austenitic Stainless Steel

Proper maintenance extends the service life of austenitic stainless steel and ensures it retains its corrosion resistance and appearance, especially for food grade stainless steel applications.

- Clean regularly with mild soap and water

- Avoid chloride-containing cleaners

- Rinse and dry after cleaning

- Use non-abrasive cloths or brushes

- Apply passivation treatment periodically (In industrial manufacturing)

- Avoid prolonged contact with acidic or salty substances

- Remove metal shavings or particles immediately

- Inspect welded joints and crevices

- Store in a clean, dry environment

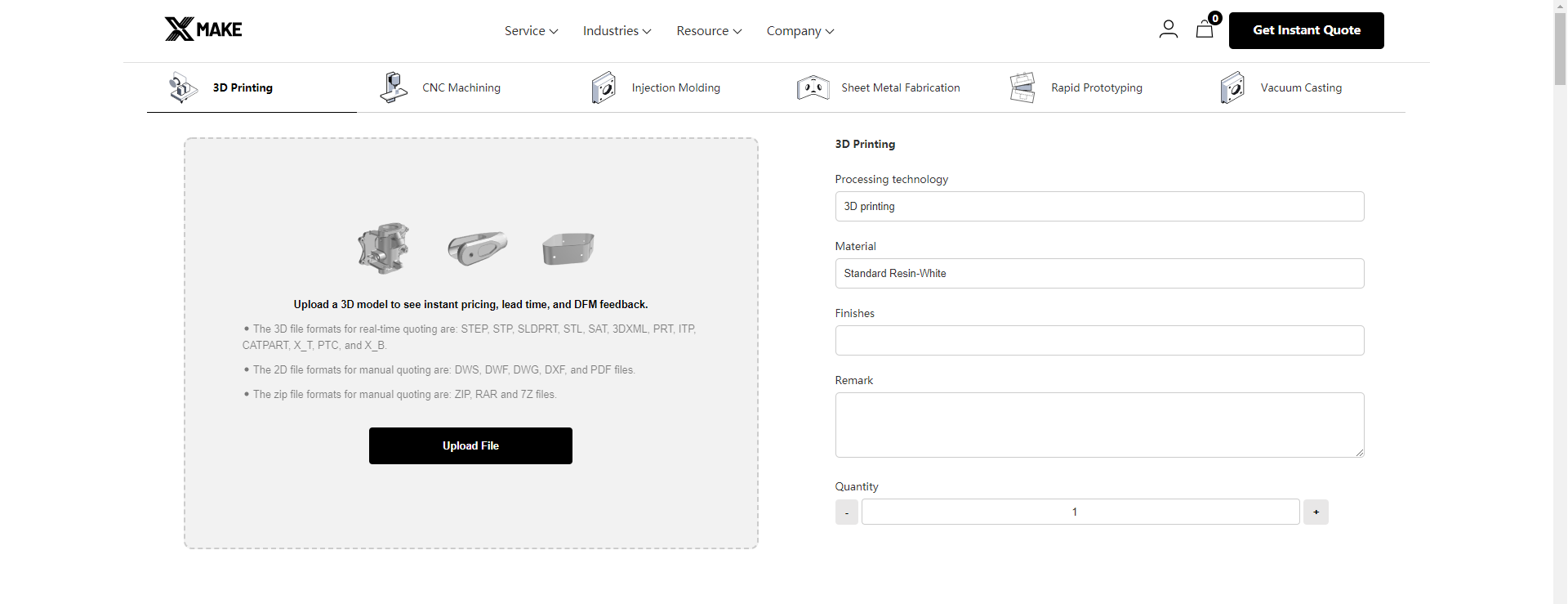

Partnering with Xmake

Austenitic stainless steel, especially the 300 series, remains a top choice across industries for its strength, corrosion resistance, and versatility. At Xmake, we offer precision CNC machining services tailored for austenitic stainless steels, ensuring high-quality parts and quick online quoting for your projects.

FAQs

1. What is the difference between austenitic and martensitic stainless steel?

Austenitic stainless steel has a face-centered cubic structure, offering excellent corrosion resistance and high ductility, but it’s not hardenable by heat treatment. Martensitic stainless steel has a body-centered tetragonal structure, is magnetic, can be hardened by heat treatment, but generally offers lower corrosion resistance.

2. How does it compare to duplex stainless steel?

Austenitic stainless steel is more formable and weldable, with better cryogenic toughness, while duplex stainless steel combines austenitic and ferritic structures for higher strength and better resistance to stress corrosion cracking.

3. Why is austenitic stainless steel non-magnetic?

Its face-centered cubic crystal structure prevents magnetic ordering of iron atoms, making it essentially non-magnetic in annealed condition, although slight magnetism can develop after cold working.