Brass has been shaping human craftsmanship and industry for centuries, prized for its warm golden hue, excellent corrosion resistance, and versatility in both functional and decorative roles. Brass remains a go-to material for countless applications.

Its unique blend of copper and zinc, plus small amounts of other elements, allows manufacturers to fine-tune properties for strength, machinability, or aesthetic appeal.

Understanding Brass

Brass is a metal alloy primarily composed of copper and zinc, valued for its balance of strength, corrosion resistance, and attractive gold-like appearance. The exact ratio of copper to zinc can vary depending on the intended application, with higher copper content generally enhancing corrosion resistance and higher zinc content increasing strength and hardness.

Beyond its base metals, small quantities of other elements, such as lead, tin, aluminum, or manganese, are sometimes added to improve machinability, wear resistance, or color tone. This adaptability makes brass a popular choice across industries, from decorative hardware and musical instruments to precision-engineered components.

Composition of Brass

The composition of brass typically ranges between 55–95% copper and 5–45% zinc, with the most common grades containing about 60–70% copper. The addition of zinc to copper not only changes its color from reddish to a warm yellow-gold but also significantly alters its mechanical properties.

Minor alloying elements may be included for specialized performance:

- Lead (0.5–3%) – Improves machinability by helping the metal break into small chips during cutting.

- Tin (≤1%) – Enhances corrosion resistance, particularly in marine environments (as in naval brass).

- Aluminum or Manganese (<1%) – Increases strength and resistance to tarnishing.

- Silicon or Nickel (<1%) – Used in specialty brasses for improved wear and chemical resistance.

Modern environmental regulations have also led to the development of lead-free brasses, which maintain machinability while meeting health and safety standards, especially in plumbing and potable water applications.

Properties of Brass

Brass exhibits a unique combination of mechanical, physical, and chemical properties that make it highly versatile for a wide range of industrial and decorative applications. Below, we break down these properties into key categories for a comprehensive understanding.

Mechanical Properties

| Property | Value | Unit |

| Density | 7.20 – 9.69 | g/cm³ |

| Tensile Strength, Ultimate | 20.7 – 1030 | MPa |

| Yield Strength | 34.5 – 683 | MPa |

| Shear Strength | 205 – 531 | MPa |

| Elongation at Break | 1.00 – 68.0 | % |

| Hardness (Brinell) | 37.0 – 155 | HB |

| Machinability | Excellent (up to 85%) | Relative to free-machining steel |

Source: MatWeb – C26000 Cartridge Brass

Physical Properties

Brass’s physical characteristics contribute to its versatility in many industrial and decorative applications. Its density, melting point, and conductivity are key factors that influence how it performs under different conditions.

- Density: Approximately average 8.51 g/cm³, which gives brass a solid and durable feel.

- Melting Point: Ranges between 900°C and 940°C, depending on the specific alloy composition.

- Thermal Conductivity: About 109 W/m·K, enabling efficient heat dissipation in heat exchanger parts and electrical components.

- Electrical Conductivity: Typically 28–45% of pure copper’s conductivity (IACS), making it useful for electrical connectors and terminals.

- Other Physical Traits: Brass is non-magnetic and has good acoustic properties, which is why it’s often used in musical instruments.

Chemical Properties

The chemical stability of brass enhances its durability and hygiene, making it suitable for a wide range of environments. Its copper content plays a major role in its corrosion resistance and antimicrobial behavior.

- Corrosion Resistance: Brass resists corrosion from air, water, and many chemicals, which is why it is commonly used in plumbing and marine applications.

- Antimicrobial Properties: Brass naturally inhibits the growth of bacteria and other microbes on its surface, beneficial in medical and food-related uses.

- Patina Formation: Over time, brass can develop a protective patina that further guards against corrosion while adding aesthetic character.

- Sensitivity: Brass may suffer from dezincification in certain environments if not properly alloyed, which is a selective leaching of zinc that weakens the metal.

Brass Color Qualities

One of brass’s most recognizable features is its warm, gold-like color, which varies based on its copper-to-zinc ratio. Higher copper percentages lend a deeper reddish tone, while increased zinc content lightens the color to a brighter yellow. Brass can also develop a natural patina over time, enhancing its aesthetic appeal in decorative contexts.

Types of Brass

Brass comes in a variety of types tailored to meet different industrial, commercial, and specialized needs. Understanding these types helps manufacturers and designers select the right alloy for their specific application.

Common Commercial Types

Among the most widely used brass alloys are several commercial types that balance cost, machinability, strength, and corrosion resistance for everyday applications:

- Cartridge Brass

Cartridge brass typically contains about 70% copper and 30% zinc. It is known for excellent ductility, making it ideal for forming and deep drawing processes. Its name originates from its use in ammunition casings, but today it’s also found in plumbing fixtures and decorative hardware.

- Naval Brass

Naval brass usually has around 60% copper, 39% zinc, and 1% tin. The addition of tin significantly improves its resistance to corrosion in seawater, making it a preferred choice for marine fittings, shipbuilding, and other applications exposed to harsh marine environments.

- Red Brass

Containing roughly 85% copper, 5% zinc, and small amounts of lead or tin, red brass has a rich reddish color and good corrosion resistance. It’s often used in plumbing, electrical connectors, and musical instruments due to its attractive appearance and durability.

- Free-Cutting Brass

Also called free-machining brass, this type includes small amounts of lead (usually 2-3%) to enhance machinability. It produces clean chips and reduces tool wear, making it popular for CNC machining and precision parts manufacturing.

Special-Purpose Types

Beyond general commercial alloys, some brass types are engineered for highly specialized functions where unique properties are essential:

- Musical Instrument Brass

This brass is formulated to optimize acoustic qualities such as tone, resonance, and workability. Variations in copper and zinc ratios, along with precise manufacturing, ensure instruments like trumpets and trombones achieve the desired sound characteristics.

- High-Tensile Brass

Designed for structural applications, high-tensile brass offers increased strength and durability. It’s often used in high-pressure fittings, heavy-duty valves, and components where mechanical stress is significant.

Short Mention of Naming Conventions

Brass alloys are systematically categorized and referenced using standard naming systems to ensure consistency and clarity across industries:

- UNS Numbers (Unified Numbering System) assign unique identifiers (e.g., C26000 for cartridge brass) that classify alloys based on chemical composition.

- ASTM Standards specify technical requirements for brass materials, such as ASTM B16 or ASTM B21, which cover wrought copper and copper alloy rods, bars, and shapes.

These conventions allow engineers, suppliers, and manufacturers to communicate precisely about the specific brass grade being used or procured.

Classification of Brass Alloys

Brass alloys are commonly classified into three microstructural categories based on their copper-to-zinc ratios and resulting phases:

- alpha (α) brass

- alpha-beta (α-β) brass

- beta (β) brass

This classification helps determine their mechanical properties, corrosion resistance, and best manufacturing methods.

Alpha (α) Brass

Alpha brass contains less than approximately 35% zinc and consists primarily of a single alpha phase, a solid solution of zinc in copper. This microstructure gives alpha brass excellent ductility, corrosion resistance, and good cold-working properties. Because of its softness and flexibility, alpha brass is ideal for applications requiring forming, such as deep drawing and stamping.

Alpha-Beta (α-β) Brass

With zinc content between roughly 35% and 45%, alpha-beta brass has a two-phase microstructure consisting of both alpha and beta phases. This combination imparts higher strength and hardness compared to alpha brass, but at the expense of some ductility. Alpha-beta brasses are often heat-treated to optimize their balance of strength and formability. They are well-suited for hot-working processes like forging and extrusion, as well as machining.

Beta (β) Brass

Beta brass contains zinc levels above 45%, predominantly featuring the beta phase, which is harder and more brittle than the alpha phase. This alloy type exhibits high strength and hardness but limited ductility, making it less suitable for cold working.

Beta brass is typically used in hot-forming operations and requires controlled processing to avoid cracking. Due to its brittleness, it’s more often applied where high mechanical strength is critical, such as in heavy-duty valves or fittings.

Suitable Manufacturing Methods

- Alpha Brasses: Best suited for cold working processes, including rolling, stamping, and deep drawing. Their softness and ductility make them excellent for producing thin sheets, intricate parts, and decorative items.

- Alpha-Beta Brasses: Can undergo hot working such as forging, extrusion, and hot rolling to capitalize on their increased strength. They also machine well and are commonly used for turned components.

- Beta Brasses: Generally processed through hot working methods only due to brittleness at room temperature. Heat treatment can improve machinability, but careful temperature control is necessary to avoid cracking.

Brass vs. Bronze

Brass and bronze are two widely used copper alloys that often get confused due to their similar appearances and overlapping applications. However, their compositions, properties, and uses differ significantly, making each better suited for specific purposes.

Composition Differences

- Brass is primarily an alloy of copper (Cu) and zinc (Zn). The zinc content typically ranges from 5% to 45%, allowing for variations in strength, ductility, and color.

- Bronze, on the other hand, is primarily a copper alloy with tin (Sn) as the main alloying element, usually between 5% and 12%. Some bronze alloys also include elements like phosphorus, aluminum, or silicon to enhance certain properties.

Property Comparison

|

Property |

Brass |

Bronze |

|

Composition |

Copper + Zinc |

Copper + Tin (mainly) |

|

Color |

Yellow to reddish-gold |

Reddish-brown to brown |

|

Strength |

Moderate to high (depends on Zn) |

Generally higher strength |

|

Corrosion Resistance |

Good, especially for atmospheric and water corrosion |

Excellent, especially in marine and industrial environments |

|

Machinability |

Excellent, especially leaded grades |

Usually lower machinability; some types require specialized tooling |

|

Wear Resistance |

Moderate |

Superior wear and fatigue resistance |

|

Density |

'8.4 g/cm³ |

'8.8 g/cm³ |

|

Cost |

Generally lower |

Typically higher due to tin and alloying |

Application

- Brass is often chosen for applications requiring good machinability, aesthetic appeal, and moderate corrosion resistance. Typical uses include plumbing fittings, musical instruments, decorative hardware, and electrical connectors.

- Bronze is favored in environments requiring superior strength, wear resistance, and corrosion protection, especially in marine, industrial, and bearing applications. Examples include ship propellers, bushings, and heavy-duty valves.

-

Cost Considerations

Brass alloys are generally more affordable and widely available due to the lower cost of zinc compared to tin. Additionally, brass’s excellent machinability reduces manufacturing costs.

Bronze, while offering superior durability and corrosion resistance, tends to be more expensive and may require more specialized processing.

Brass: Pros and Cons

Brass offers a balanced mix of advantages and disadvantages that influence its suitability for various applications.

Pros:

- Excellent corrosion resistance in many environments.

- High machinability, especially in leaded and free-cutting grades.

- Attractive gold-like appearance suitable for decorative uses.

- Good thermal and electrical conductivity.

- Natural antimicrobial properties beneficial for sanitary applications.

- Easily recycled, contributing to sustainability efforts.

Cons:

- Susceptible to dezincification in certain corrosive environments if improperly alloyed.

- Lead content in some grades raises health and environmental concerns.

- Generally softer than steel, limiting its use in high-wear structural applications.

- Can tarnish and develop patina over time, requiring maintenance for aesthetic purposes.

- Costlier than some alternative alloys like aluminum or standard steel.

Can Brass Be CNC Machined?

Brass is highly favored in CNC machining thanks to its excellent machinability, which enables precise cutting and smooth finishes with minimal tool wear. Its predictable chip formation and dimensional stability make it ideal for complex, high-precision components.

Common brass parts produced by CNC machining include:

- Plumbing fittings and valves

- Electrical connectors and terminals

- Musical instrument components

- Decorative hardware and fixtures

- Mechanical gears and bushings

- Precision fasteners and small mechanical parts

Final Thought

Brass remains a versatile and reliable material, prized for its combination of strength, machinability, and aesthetic appeal across various industries. Whether for decorative applications or precision mechanical parts, brass offers unmatched adaptability and performance.

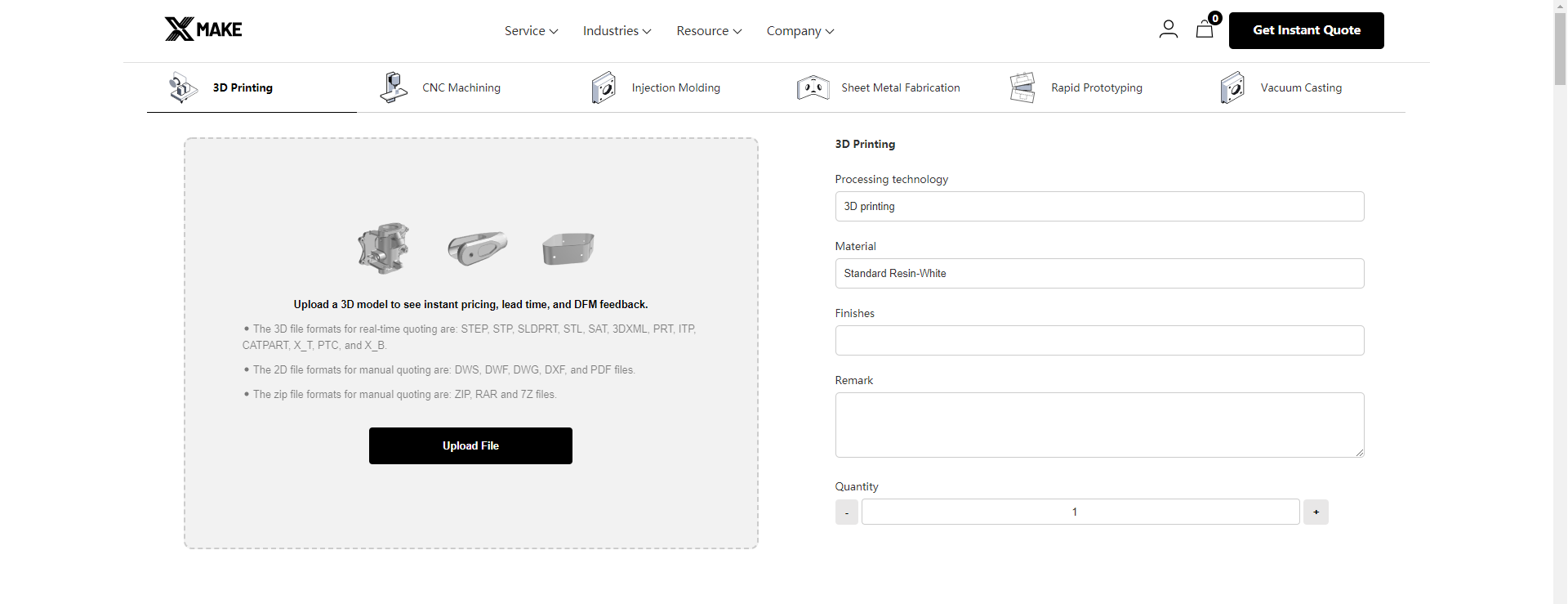

At Xmake, we specialize in CNC machining brass components with high precision and quick turnaround, helping you bring your projects to life efficiently and reliably.

FAQs

Q1: Is brass magnetic?

Brass is non-magnetic because it’s made mainly of copper and zinc, which don’t respond to magnets. This property makes brass ideal for electrical and precision applications where magnetism could cause issues.

Q2: Does brass tarnish over time?

Yes, brass naturally tarnishes as it reacts with air and moisture, forming a patina that can protect it from further corrosion. If you prefer a shiny finish, regular polishing can easily restore its bright appearance.

Q3: What is the difference between solid brass and brass-plated items?

Solid brass is made entirely from the alloy, offering consistent durability and corrosion resistance throughout. Brass-plated items have only a thin brass layer over another metal, which can wear off and expose the base material over time.