Knurling is a specialized machining process used to create patterned textures on the surface of a workpiece, most commonly for functional grip or decorative appeal. This technique is widely recognized in metalworking and manufacturing, such as on tool handles, instrument knobs, or mechanical fasteners.

To help you better understand how knurling works in real-world applications, we’ve selected a video that provides a clear and practical demonstration of the process.

▶️ Watch this video to see knurling in action and understand the basics visually.

What Is Knurling?

Knurling is a machining process that produces a series of textured ridges or patterns on the surface of a material, typically metal, by pressing or cutting with a specialized tool.

The most noticeable feature of a knurled surface is its tactile texture:

- raised lines

- intersecting grooves that form a regular, repeating pattern

These patterns are not just for appearance; they serve a functional purpose. By altering the surface geometry, knurling increases friction, making the component easier to grip or handle, even in oily or high-vibration environments. You’ll often find these patterns on tool handles, adjustment knobs, or mechanical components where manual control or torque is required.

Depending on the tool and method used, the resulting surface may vary in depth, spacing, and geometry. While the patterns differ, what they all share is a distinct, engineered texture that enhances usability and often adds a layer of visual sophistication to an otherwise plain surface.

Functions of Knurling

Knurling serves several practical functions in manufacturing and product design, particularly when performance, safety, and usability are critical. Here are the key purposes of knurling:

- Improved Grip: The raised texture increases surface friction, making it easier to hold or operate components, especially in oily, wet, or high-vibration conditions.

- Anti-Slip Control: On-hand tools or adjustment dials, knurled surfaces reduce the risk of slippage during manual operation, enhancing user control and safety.

- Enhanced Torque Transfer: In mechanical systems, knurling helps transmit torque more effectively when users apply rotational force by hand.

- Press Fit Assistance: In assembly, a knurled shaft can create an interference fit with a mating component, improving retention without adhesives or fasteners.

- Visual and Tactile Identification: Knurling can be used to differentiate controls or surfaces by feel alone, which is especially useful in low-visibility or fast-paced environments.

- Aesthetic Enhancement: Beyond its functional role, knurling adds a technical or industrial design element that can improve the perceived quality of a product.

Though subtle, these functions are essential in product performance, safety, and user experience.

How Knurling Is Made?

While knurled patterns may seem simple on the surface, producing them involves precise methods, proper tooling, and an understanding of material behavior under pressure.

If you’ve already watched the video we shared earlier, you’ve seen how knurling tools interact with rotating workpieces to create those distinct patterns. This section will break down the main techniques, tools, and parameters that shape how knurling is actually performed in real-world machining setups.

Let’s begin with the machinery and tools used in the process.

Knurling Tools and Machines

Knurling is typically performed on a lathe, either manually or using CNC controls. The process requires specialized tools designed to impress or cut a pattern into the rotating workpiece. These tools come in several forms, depending on the method and desired outcome:

- Knurling Wheels (or Rollers): These hardened steel wheels have a patterned surface that is pressed against the material to form the knurl. They are the most common tools used for form knurling.

- Knurling Dies: In some production environments, especially in automated or high-volume setups, die heads equipped with knurling profiles are used for consistent and fast pattern formation.

- Cut Knurling Tools: These tools have sharp edges and are used to slice into the material to generate the pattern, rather than deforming it. This method is often preferred for harder materials or when a cleaner finish is required.

- Manual vs CNC Machines: Manual lathes require an experienced operator to apply pressure and align the tool correctly. CNC lathes, on the other hand, can automate tool positioning, feed rates, and dwell times, making them ideal for repeatable, high-precision knurling.

Whether working with manual or CNC equipment, the quality of the knurl is highly dependent on tool alignment, pressure, and synchronization with the workpiece rotation. Improper setup can lead to surface defects or mismatched patterns, which we’ll explore later in the challenges section.

Knurling Processes

The two main approaches to creating knurled patterns are form knurling and cut knurling. While both achieve similar surface textures, they differ significantly in technique, tooling, and material interaction.

- Form Knurling

This method relies on plastic deformation. The knurling tool is pressed against the rotating workpiece with sufficient pressure to displace material and form the pattern. No cutting occurs; instead, the surface is reshaped under compressive force.

✅Advantages: Fast, cost-effective, and ideal for ductile materials like aluminum, brass, or mild steel.

✅Considerations: Not suitable for very hard materials. Excessive force can distort dimensional tolerances if not controlled carefully.

- Cut Knurling

In contrast to forming, cut knurling uses tools with sharp edges that remove material as the part rotates. The tool feeds into the surface, carving out the knurled pattern with precision.

✅Advantages: Produces cleaner edges and is better suited for harder metals such as stainless steel or tool steel. Also reduces radial force on the workpiece.

✅Considerations: Requires more precise control and longer cycle time. More tool wear compared to the form knurling.

Each method has its place depending on the workpiece material, tolerance requirements, and the desired visual finish. In practice, form knurling is more commonly used in general-purpose applications, while cut knurling is preferred when surface quality and precision are paramount.

Machine Settings and Parameters

The quality of a knurled surface depends not only on the tool but also on how the process is set up. Key factors such as:

- spindle speed

- feed rate

- tool pressure

- alignment

All influence the consistency and clarity of the pattern. Proper adjustments ensure the knurl forms cleanly without defects, while the right lubrication and tool positioning help maintain surface integrity and prolong tool life. Regardless of the machine type, careful setup is essential for achieving reliable results.

Types of Knurling Patterns

Knurled surfaces can take on a variety of patterns, each designed to meet different functional or aesthetic needs. While all knurling creates textured surfaces for grip or assembly, the specific geometry of the pattern can influence how the component performs, feels, or fits into another part. The choice of pattern often depends on the application.

Below are the most commonly used knurling patterns in industrial and product design.

Straight Knurl

Image: Straight Knurling (right side)

This pattern features parallel ridges running perpendicular to the axis of the workpiece. Straight knurls provide a firm axial grip and are often used on push-pull components or where rotational grip isn’t necessary.

Diagonal Knurl

Image: Diagonal Knurling (ring surface)

Diagonal knurling consists of angled ridges that run in a single direction, typically at 30° or 45° to the workpiece axis. The grooves can be configured in a right-hand or left-hand orientation, depending on the desired torque direction or visual style. This type is widely used for improved rotational grip in fasteners, knobs, and hand tools.

Diamond Knurl

Image: Diamond Knurling (ring surface)

This pattern is formed by overlapping right-hand and left-hand diagonal knurls, creating a distinct crisscross or diamond shape. It provides superior grip in multiple directions and is the most popular knurl type in both industrial and consumer applications.

Annular Knurl

Image: Annular Knurling (left side)

Annular knurls consist of concentric circular ridges around the circumference of the part. This pattern is used less frequently but is ideal for press-fit applications, as the rings help secure the part within a mating hole.

Knurling Standards

To ensure functionality, consistency, and compatibility with mating components, knurling must adhere to defined specifications. These parameters help determine the final pattern, depth, and fit of the knurled surface. Manufacturers often refer to international or industry standards to guide tool selection and setup.

Key specifications include:

- Knurl Pitch (or TPI – Teeth Per Inch): This defines the spacing of the pattern. It is usually categorized as coarse, medium, or fine. Coarser pitches are suited for larger components and heavier grip, while finer pitches are used for smaller parts or aesthetic purposes.

- Pattern Geometry: Standards define the angle and depth of grooves, especially for diamond and diagonal knurls. For example, 30° and 45° diagonal angles are common.

- Diameter Considerations: The workpiece diameter must be compatible with the pitch to avoid pattern mismatches or double tracking. Some tooling charts offer “preferred diameters” for clean pattern formation.

- Tolerance and Fit: In press-fit applications, knurl depth affects how tightly a component fits into a mating part. The deformation must be accounted for in the overall dimensional tolerances.

- Standard References: Commonly used standards include ANSI B94.6 (for inch-based knurling), ISO 13444 (international knurling parameters), and DIN 82 (European specifications for pattern types and dimensions).

Following established specifications not only ensures performance and manufacturability but also facilitates communication across teams, suppliers, and clients in precision manufacturing environments.

✅Read more: ISO 2768: Explaining CNC Machining Tolerance Standards

Common Knurling Defects

Despite being a straightforward process in principle, knurling can present several technical challenges that affect surface quality, pattern alignment, and functional performance.

|

Double Tracking |

Pattern appears misaligned or overlapped due to incompatible diameter or feed. |

|

Misalignment |

One side of the pattern is deeper than the other, indicating poor tool setup. |

|

Surface Tearing |

Rough or cracked texture due to excessive pressure or dry machining. |

|

Shallow Knurling |

Insufficient tool pressure results in barely visible ridges. |

|

Tool Wear Pattern |

Pattern becomes dull or distorted after repeated use of a worn knurling wheel. |

Choosing the Right Knurling

- Functionality: If grip is the main priority (as with hand tools or knobs), diamond or diagonal patterns are ideal. For press-fit assemblies, annular rings or straight knurls provide better surface interference.

- Material Type: Softer metals like aluminum and brass are well-suited for form knurling, while harder materials such as stainless steel may require cut knurling to maintain pattern integrity without damaging the tool.

- Component Size and Geometry: Finer knurl pitches are recommended for smaller parts to maintain pattern visibility and tactile quality, while coarse pitches are better for larger surfaces.

- Production Volume: For high-volume production, CNC knurling ensures repeatability and efficiency. Manual knurling is more practical for prototypes, repairs, or low-run custom components.

- Aesthetic vs. Functional Priorities: Some designs use knurling primarily for visual appeal. In these cases, pattern symmetry, finish, and alignment take precedence over depth or grip.

- Environmental Conditions: In environments with oil, moisture, or vibration, more aggressive knurl patterns enhance user control and reduce slippage.

Applications of Knurling

Knurling is widely used across industries where grip, precision, and mechanical performance are essential. From everyday tools to specialized industrial components, its presence enhances both functionality and form. Below are some of the most common application areas:

- Tooling and Hand Tools: Knurled surfaces are standard on screwdrivers, pliers, and handles to provide a firm, non-slip grip for manual tasks.

- Fasteners and Thumbscrews: Many fasteners, especially thumb screws and knobs, feature knurling to allow easy tightening or loosening by hand without the need for tools.

- Electronic and Instrument Controls: Dials, knobs, and rotary switches on measuring instruments, audio equipment, or industrial control panels often feature knurled textures for precise manual adjustment.

- Press-Fit Mechanical Assemblies: In mechanical engineering, knurled shafts or pins are used in press-fit joints, where the textured surface helps maintain a secure fit without additional hardware.

- Bicycle and Automotive Components: Parts such as foot pegs, brake levers, and gear shifters often use knurling to enhance grip and control under varying conditions.

- Consumer Products and Packaging: High-end product packaging (such as perfume bottles or cosmetics) may incorporate knurling as a tactile design feature that also aids in opening and closing.

These applications highlight the versatility of knurling, not just as a practical enhancement but also as a subtle design element that adds both usability and character to a component.

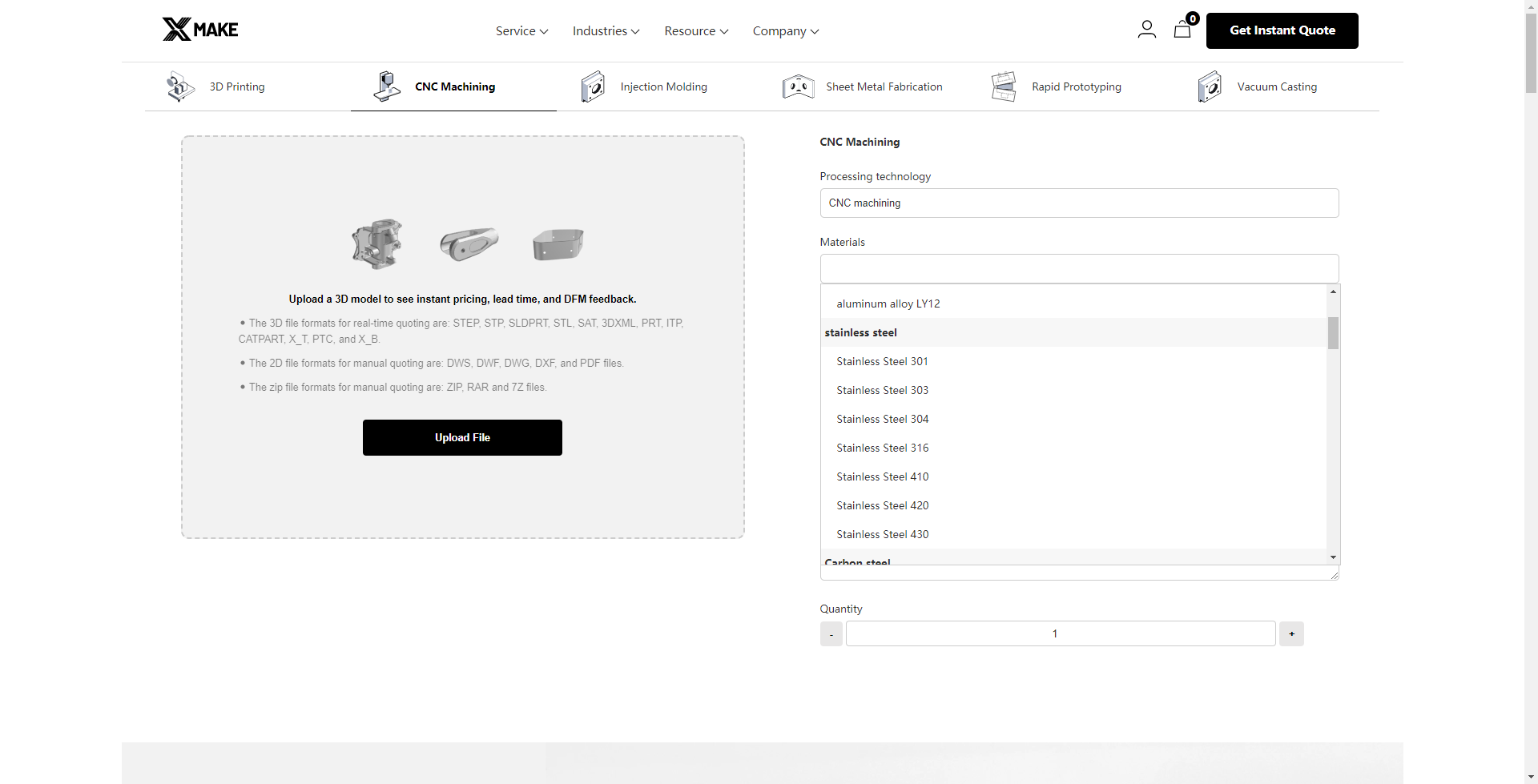

How Xmake Can Help?

Knurling is far more than a decorative surface treatment; it’s a functional and precise engineering process that enhances grip, enables press-fit assemblies, and elevates product quality across multiple industries.

As part tolerances tighten and user expectations rise, knurling remains a reliable solution that balances form and function. With the insights from this guide, you’re better equipped to specify, evaluate, or implement knurling with confidence.

As a leading provider of CNC machining services, Xmake integrates advanced knurling capabilities into our precision manufacturing workflow, delivering consistently accurate, repeatable patterns on a wide range of materials and geometries.

Frequently Asked Questions

1. What is the purpose of knurling on metal parts?

Knurling enhances grip, aids in press-fit assemblies, and improves the tactile or visual appeal of a component. It’s commonly used in tools, knobs, and mechanical parts.

2. What materials can be knurled?

Knurling works best on softer metals such as aluminum, brass, copper, and mild steel. Harder materials like stainless steel can also be knurled, but require more durable tooling and precise control.

3. Can you knurl without a lathe?

Yes, though a lathe is the most common and efficient method, manual knurling tools (such as hand knurlers or knurling pliers) can be used for small-scale or low-precision applications, especially on cylindrical objects. However, achieving consistent patterns and depth is more difficult without a powered machine.

4. Can plastic be knurled?

Plastic can be knurled, particularly thermoplastics like ABS or nylon. However, the process requires lower force and temperature control to prevent melting or deformation. In many cases, injection-molded parts incorporate knurled textures directly into the mold design instead of using post-processing.