Pins are simple yet indispensable components in mechanical assemblies. Pins serve a variety of essential mechanical functions across countless applications. Pins are found in nearly every type of machinery, for example:

- Securing two components

- Aligning moving parts

- Locating precise positions

- Joining structural elements

With numerous styles and materials available, selecting the right pin type can be more complex than it first appears. The wrong choice may lead to misalignment, premature wear, or even failure of the assembly.

This guide explores the most common types of pins, their typical applications, and the key factors to consider when choosing the appropriate fastener for your needs.

What Are Pin Fasteners?

Pin fasteners are mechanical components designed to secure, align, or locate parts within an assembly. Typically cylindrical in shape, they are inserted into pre-drilled holes and may be held in place by friction, deformation, or additional hardware.

Unlike threaded fasteners such as screws and bolts, pins are often simpler in design and can be used for both temporary and permanent connections, depending on the type. Their strength, durability, and ease of installation make them a staple in applications.

Choosing the right type of pin fastener involves understanding the application’s functional demands, environmental conditions, and the desired level of permanence in the joint. As such, pins are not only versatile but also strategically important in mechanical design.

Dowel Pins

Dowel pins are precision-engineered cylindrical fasteners used primarily for accurate alignment between two or more parts. They are typically made from hardened steel or stainless steel and are available in both metric and inch sizes.

Designed to fit tightly into corresponding holes, dowel pins ensure consistent, repeatable positioning during assembly and disassembly, making them essential in jigs, fixtures, dies, and high-precision machinery.

To use dowel pins, they are usually pressed into one component using an arbor press or gently tapped with a hammer. The mating part is then aligned and slid or pressed over the exposed ends of the pins. In high-precision applications, the holes are usually reamed to ensure a tight, interference fit, which keeps the pin securely in place without the need for adhesives or additional fasteners.

Taper Pins

Taper pins are conical fasteners designed to lock components together with a precise, interference fit. Their gradually narrowing shape allows them to wedge tightly into a matching tapered hole, offering excellent resistance to both axial movement and rotational forces. Installation typically involves driving the pin into a reamed hole using light hammering; removal can be done by tapping it from the small end.

There are several types of taper pins to suit different assembly needs:

- Standard taper pins for basic alignment.

- Externally threaded taper pins for use with nuts.

- Internally threaded taper pins that allow extraction using a puller.

These pins are commonly made from materials such as hardened steel, stainless steel, and occasionally brass, depending on the mechanical and corrosion-resistance requirements of the application.

Grooved Pins

Grooved pins are solid cylindrical fasteners with longitudinal grooves swaged or rolled along their surface. These grooves displace material outward, creating an interference fit when the pin is inserted into a hole. This design allows grooved pins to lock firmly in place without the need for adhesives or additional hardware, making them ideal for applications where quick, secure assembly is needed.

Typically used in light-duty fastening and alignment tasks, grooved pins are easy to install with hand or press fitting and are commonly found in handles, levers, linkages, and small mechanical assemblies. They are available in several groove configurations, such as full-length, partial, or center grooves, and are often manufactured from materials like carbon steel, stainless steel, or aluminum for various strength and corrosion resistance requirements.

Spring Pins

Spring pins, also known as roll pins, are hollow cylindrical fasteners designed to compress as they are inserted, then expand to lock securely in place. They’re favored in assemblies where shock absorption, vibration resistance, and ease of installation are key. Two primary types exist:

- Slotted spring pins

- Coiled spring pins

Slotted spring pins feature a longitudinal slot and a slightly oversized diameter. When inserted into a hole, the pin compresses along the slot, creating radial tension that keeps it firmly seated. They are cost-effective and suitable for static or low-load connections, such as securing gears, pulleys, or hand tools.

Coiled spring pins, on the other hand, are made by tightly winding steel strips into a spiral shape. This structure allows for more uniform expansion and better energy absorption under dynamic loads. They’re ideal for high-cycling applications or assemblies subject to frequent shocks, such as automotive components, machinery linkages, and hinges.

Coiled spring pins are also known as spiral pins. The term “coiled spring pin” is the formal name used in standards like ISO 8750 or ASME B18.8.2, while “spiral pin” is a more general or descriptive term based on the pin’s appearance and structure.

Their flexibility, reusability, and strength-to-weight ratio make spring pins a versatile choice across many industries.

Cotter Pins

Cotter pins, often called split pins, are simple, U‑shaped wires that lock other fasteners in place by passing through a pre‑drilled hole and then having their twin prongs bent back against the shaft. This quick “bend‑to‑secure” action prevents nuts, clevis pins, and other shaft‑mounted parts from loosening under vibration or load.

While the term “split pin” is sometimes considered synonymous with “cotter pin” (especially in British English), it can also refer more generally to any pin split down its length.

Available in low‑carbon steel, stainless steel, brass, and even aluminum for lighter duty, cotter pins are inexpensive, single‑use safeguards found in everything from trailer hitches to turbine assemblies where fail‑safe retention is essential.

Clevis Pins

Clevis pins are versatile fasteners used to connect two components that require rotation or pivoting, such as in mechanical linkages, hitch systems, or control levers. They have a cylindrical body with a flat head on one end and a cross-hole near the other, designed to accept a cotter pin or similar retainer to hold them in place.

Clevis pins are easy to install and remove; they simply slide through aligned holes and are secured without threading or complex tools. Often made from stainless steel, zinc-plated steel, or alloy steel, clevis pins combine strength with accessibility, making them a go-to choice for temporary or adjustable mechanical connections.

Clevis pins are most commonly paired with cotter pins, which pass through the hole at the end to prevent the pin from sliding out during use. This simple locking method makes them ideal for pivoting connections.

Hitch Pins

Hitch pins are heavy-duty fasteners commonly used to secure towing attachments, agricultural implements, and trailer couplings. They consist of a straight or slightly bent pin with a handle or grip at one end and a hole near the other, which accepts a retaining clip or lynch pin to lock the assembly in place. This design allows for quick, tool-free installation and removal, ideal for field operations or equipment that requires frequent connection and disconnection.

Made from high-strength steel and often zinc- or powder-coated for corrosion resistance, hitch pins are built to withstand repeated shear loads and rugged outdoor environments. Their reliability and simplicity make them indispensable in transport, farming, and industrial settings.

Lynch Pins

Lynch pins are quick-locking fasteners designed to prevent accidental disconnection of shafts, axles, or other pivot points. They consist of a solid pin with a self-locking ring, usually a spring-loaded loop that snaps over the shaft after insertion. This simple mechanism ensures the pin stays securely in place, even under vibration or movement.

Often used in tandem with hitch pins or clevis systems, lynch pins are common in agricultural machinery, trailers, and construction equipment. They’re available in various sizes and materials, such as zinc-plated or stainless steel, to offer both durability and corrosion resistance in demanding environments.

Knurled Pins

Knurled pins are solid cylindrical fasteners distinguished by their textured surface, created by a series of ridges or knurls around the body. These knurls improve friction between the pin and the hole, allowing the pin to grip firmly without the need for adhesives or secondary locking mechanisms.

Knurled pins are typically made from stainless steel, brass, or aluminum, and are often installed using simple pressing tools or hand force, depending on the material of the receiving part.

Wire Lock Pins

Wire lock pins, also known as quick-release pins, are designed for frequent assembly and disassembly without tools. They typically feature a spring-loaded ball or wire loop mechanism that snaps into place once inserted, securing the pin instantly and allowing it to be removed just as easily with a pull or press.

Wire lock pins are available in various styles, including straight, T-handle, and L-handle designs, and are usually made from corrosion-resistant stainless steel or plated steel for durability. Their ease of use and reliable locking action make them indispensable in applications where efficiency is just as important as security.

Drive Pins

Drive pins are solid fasteners designed to be driven directly into a material, for example, concrete, masonry, or metal, using a hammer or a powder-actuated tool. Drive pins are held in place by force and friction, making them ideal for permanent, high-strength installations.

These pins often have a flared or grooved shank to improve grip and prevent pull-out after installation. They’re commonly used in construction, industrial mounting, and electrical applications, such as securing conduit straps or attaching fixtures to hard surfaces.

Drive pins are usually made from hardened steel to withstand the impact of installation and to ensure long-term durability in demanding environments.

Detent Pins

Detent pins are quick-release fasteners equipped with a spring-loaded ball at the tip that locks into place once inserted, preventing the pin from sliding out unintentionally. Most designs also include a pull ring or grip ring at the top, making it easy to insert or remove the pin by hand—no tools required.

Hybrid Pins

Some pins are designed to merge characteristics of two or more standard pin types to meet specific functional or assembly needs. These specialty pins often appear in custom machinery, tooling setups, or specialized fixtures where conventional pins alone don’t offer the required performance. Below are a few common examples:

- Grooved Dowel Pins

- Threaded Dowel Pins

- Tapered Grooved Pins

These hybrid designs offer tailored solutions for complex engineering demands, and while they may not be as common as standard pins, they serve essential roles in precision and high-performance assemblies.

Image: spring-loaded pogo pins

Common Functions of Different Pin Types

Pin fasteners are used across nearly every sector of engineering and manufacturing, each type tailored to specific mechanical functions.

Locating & Positioning

Pins like dowel pins and taper pins are precision-alignment tools used to ensure accurate mating of parts. Dowel pins, for example, are widely used in mold bases or die sets to guarantee that components align perfectly every time. Taper pins are often seen in assemblies requiring repeatable positioning under load, such as in heavy machinery or press equipment.

Securing Components

For applications that demand parts stay in place under vibration or shear force, cotter pins and spring pins are popular solutions. Cotter pins are frequently used to lock nuts on axles and trailer hitches, while slotted or coiled spring pins are ideal for fastening rotating parts like gears or levers in tool handles and power equipment.

Rotation or Alignment

When two parts must pivot or rotate around a central axis, clevis pins and hinge pins are commonly used. Clevis pins, for instance, are integral to agricultural machinery and towing systems, providing both strength and ease of assembly. Hinge pins are widely applied in doors, gates, and mechanical linkages that require controlled movement.

How to Choose the Right Pin Fastener Types?

- Material Selection: Stainless steel, carbon steel, brass, or hardened alloys.

- Mechanical Requirements: Expected loads, shear forces, and whether the assembly will experience vibration or dynamic movement.

- Environmental Conditions: Exposure to moisture, chemicals, extreme temperatures, or outdoor elements that may require protective coatings or rust-resistant materials.

- Fit and Tolerance: Decide between an interference fit (tight and secure) or a clearance fit (easy to assemble/disassemble).

- Installation and Removal: Determine whether the pin needs to be permanent or removable.

By evaluating these factors together, engineers can ensure the selected pin not only fits the design but also performs reliably over time in its intended environment.

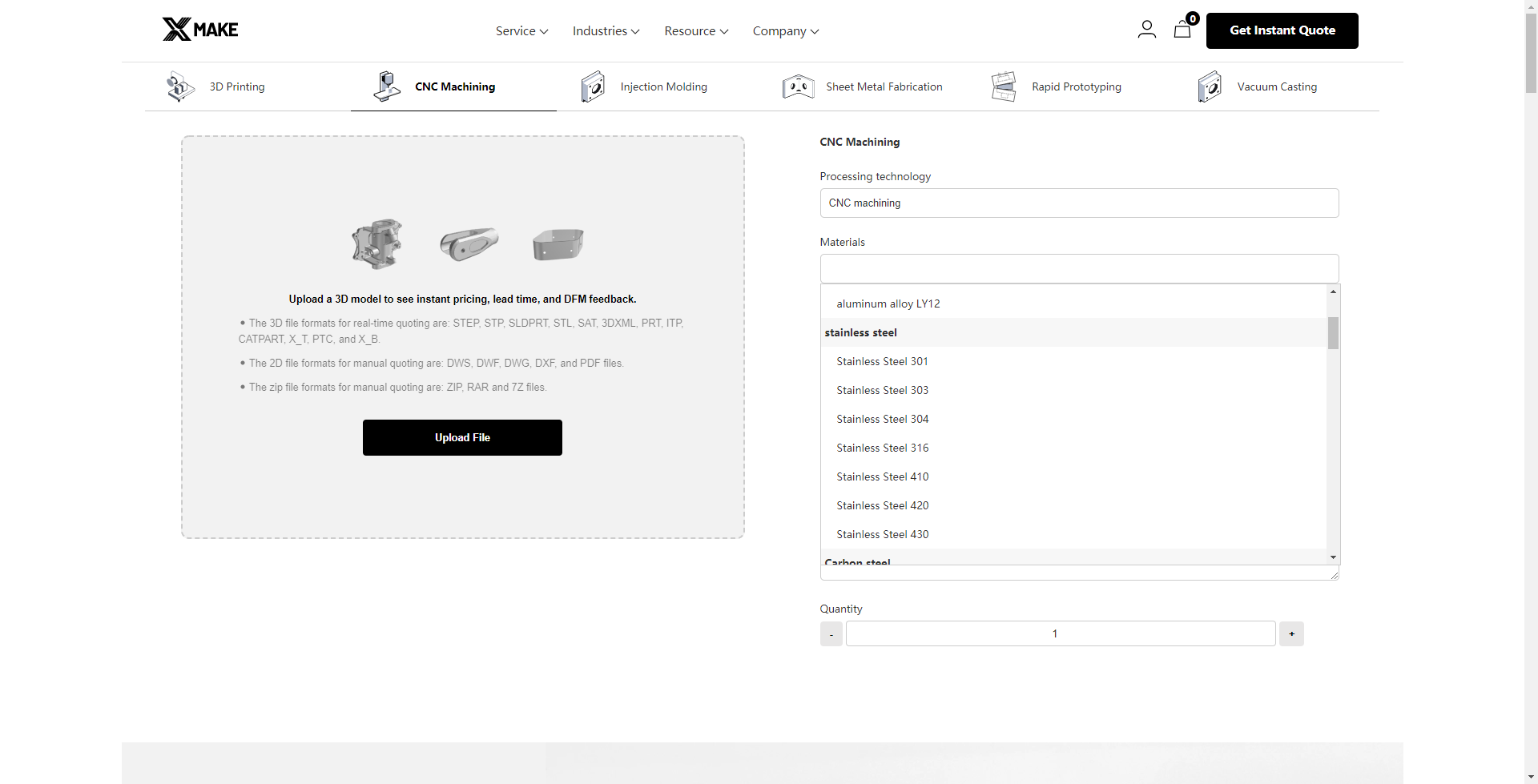

How Xmake Can Help?

Frequently Asked Questions

1. What are the types of pins used in mechanical engineering?

In mechanical engineering, the most common types of pins include dowel pins, taper pins, grooved pins, spring pins (both slotted and coiled), clevis pins, cotter pins, and hitch pins. Each serves a specific function. The choice depends on the application’s load, fit, and assembly requirements.

2. Which pin fastener is best for high vibration?

Coiled spring pins (also known as spiral pins) are among the best choices for high-vibration environments. Their layered, flexible structure allows them to absorb shock and movement without loosening or cracking, making them ideal for dynamic assemblies such as machinery, automotive components, or tools with repetitive motion.

3. Are dowel pins reusable?

Dowel pins can be reusable, but it depends on the type of fit and the material condition after removal. In slip-fit applications, where pins are inserted and removed without force, they are often reused without issue. However, in interference-fit applications, removal may cause wear or damage, making reuse less reliable. Always inspect dowel pins for wear, deformation, or loss of tolerance before reusing them in critical assemblies.