As demand for faster, more flexible, and cost-effective production methods grows, understanding the different types of 3D printing becomes crucial. Each technology offers distinct advantages depending on the application, material, and complexity involved. Some common 3d printing types include:

- Fused Deposition Modeling (FDM)

- Stereolithography (SLA)

- Multi Jet Fusion (MJF)

- Digital Light Processing (DLP)

- Selective Laser Melting (SLM)

- Selective Laser Sintering (SLS)

For those without industrial-grade machines at their fingertips, 3D printing services act as the bridge between concept and creation. This guide explores 12 different types of 3D printing technologies and shows you how to choose the one that fits your project best.

1. SLA (Stereolithography)

Stereolithography, or SLA, is one of the earliest and most precise 3D printing technologies, known for using a focused UV laser to cure liquid resin layer by layer. What sets SLA apart is its ability to produce exceptionally smooth surface finishes and finely detailed features without visible layer lines, making it a benchmark for aesthetic and dimensional quality in 3D printing.

Unlike some other methods, SLA supports a wide range of photopolymer resins, including engineering-grade formulations with mechanical, thermal, or biocompatible properties.

This technology is especially favored in industries like dentistry, medical device prototyping, and jewelry design, where detail resolution and surface quality are critical from the first print.

2. MJF (Multi Jet Fusion)

Multi Jet Fusion (MJF) is a powder-based 3D printing technology developed by HP, designed for producing strong, functional parts with excellent surface quality and dimensional accuracy.

Unlike laser-based methods, MJF uses a fusing agent and detailing agent that are selectively jetted onto a nylon powder bed, which is then fused using infrared energy. This results in parts with isotropic mechanical properties, meaning they perform consistently across all directions, and without the brittleness sometimes found in sintered parts.

One of MJF’s most distinctive advantages is its production speed and ability to create fully functional prototypes and end-use parts in less time than traditional methods. It’s widely used in the automotive, consumer electronics, and medical device industries where durability, fine detail, and quick turnaround are essential.

3. FDM (Fused Deposition Modeling)

Fused Deposition Modeling (FDM) is one of the most accessible and widely used types of 3D printing, both in hobbyist and industrial settings. It works by extruding a thermoplastic filament through a heated nozzle, which deposits material layer by layer to build a part from the bottom up.

The process is relatively simple, cost-effective, and compatible with a variety of plastics such as PLA, ABS, PETG, and even engineering-grade materials like ULTEM and carbon fiber composites. FDM stands out for its scalability, ease of use, and low material costs, making it ideal for everything from concept models and functional prototypes to jigs, fixtures, and low-volume production parts.

FDM is inexpensive primarily because it uses readily available thermoplastic filaments, has relatively simple hardware, and requires minimal post-processing. Unlike resin- or powder-based systems, FDM machines don’t need complex laser systems or controlled environments, which significantly reduces operational and maintenance costs.

4. SLS (Selective Laser Sintering)

Selective Laser Sintering (SLS) is a powder-based 3D printing type that uses a high-powered laser to sinter thermoplastic powder particles layer by layer. By heating the powder just below its melting point, SLS fuses particles to form solid parts with good mechanical properties and complex geometries. Because it does not require support structures, the surrounding powder acts as natural support. SLS is especially effective for creating intricate designs and functional prototypes.

SLS is popular in industries such as aerospace, automotive, and consumer products for producing durable plastic parts with excellent strength, heat resistance, and design freedom, making it a versatile and widely adopted 3D printing solution.

5. SLM (Selective Laser Melting)

Selective Laser Melting (SLM) is a high-performance metal 3D printing technology that fully melts fine metal powder using a powerful laser, creating dense, complex parts with excellent mechanical strength.

SLM achieves complete fusion of the metal particles, resulting in near-wrought material properties and exceptional structural integrity. It operates in a tightly controlled inert gas environment to prevent oxidation during printing, which is essential when working with reactive metals like titanium or aluminum.

SLM stands out in the world of 3D printing for its ability to produce intricate, load-bearing components used in aerospace, medical implants, motorsports, and other demanding industries where lightweight performance and precision are critical.

6. DLP (Digital Light Processing)

Digital Light Processing (DLP) is a resin-based 3D printing type that cures liquid photopolymer using a digital light projector. Each layer is exposed all at once, making DLP significantly faster than SLA, which traces each layer point by point with a laser. Both offer excellent resolution and surface quality, but DLP is better for speed, especially on wider prints, while SLA may offer slightly finer detail on small features.

DLP is widely used in dental models, jewelry prototypes, and high-precision design work. Its combination of speed, accuracy, and compact hardware makes it a go-to solution for professionals who need detailed results on tight timelines.

7. EBM (Electron Beam Melting)

Electron Beam Melting (EBM) is a metal 3D printing process that uses a focused beam of electrons (rather than a laser) to fully melt metal powder, layer by layer, in a high-vacuum chamber. The process is typically performed at elevated temperatures, which helps relieve internal stresses during printing and results in parts with excellent mechanical properties and low residual stress.

EBM is especially effective with materials like titanium alloys, making it a popular choice in aerospace and medical implant manufacturing.

What sets EBM apart is its ability to build dense, high-performance metal parts with minimal distortion, especially when printing complex geometries that are prone to warping in laser-based systems. Its vacuum environment also makes it well-suited for reactive metals that are difficult to process using traditional methods.

8. DMLS (Direct Metal Laser Sintering)

Direct Metal Laser Sintering (DMLS) is a metal 3D printing type that builds complex parts by sintering fine metal powder layer by layer using a high-powered laser. Unlike melting-based processes like SLM, DMLS does not fully liquefy the material; instead, it fuses the particles just below the melting point, which allows for the use of a wide range of metal alloys, including those that are difficult to weld or cast using traditional methods.

DMLS is especially valuable for producing intricate, functional metal components with internal channels, lattice structures, or organic geometries that would be impossible or too costly to machine. It’s widely used in aerospace, medical, and industrial applications where design freedom, mechanical performance, and material diversity are all critical.

9. PolyJet

PolyJet is a high-resolution 3D printing type that jets tiny droplets of liquid photopolymer onto a build tray, where each layer is instantly cured with UV light. What sets PolyJet apart is its ability to print multiple materials, colors, and levels of rigidity within a single build, making it ideal for complex prototypes that require visual realism or mixed material properties. The technology offers exceptional surface finish and fine detail, often surpassing SLA in visual quality.

PolyJet is one of the most prominent implementations of Material Jetting, often associated with Stratasys systems. It is widely used in industrial design, medical modeling, and consumer product development, particularly when there’s a need to simulate textures, overmolds, or multi-material assemblies in a single print. Its precision and material versatility make it one of the most advanced prototyping tools available.

10. LOM (Laminated Object Manufacturing)

Developed in the early 1990s by Helisys Inc. in California, Laminated Object Manufacturing (LOM) was one of the first 3D printing types to use sheet-based materials instead of powders or resins.

Laminated Object Manufacturing (LOM) is a unique 3D printing type that builds objects by layering and bonding sheets of material, such as paper, plastic, or metal foil, then cutting each layer into shape using a laser or blade. Unlike most additive manufacturing methods that rely on melting or sintering, LOM uses heat and pressure to fuse the layers, creating parts with a wood-like texture and good dimensional stability.

While LOM doesn’t offer the precision or material strength of other technologies, it stands out for its speed, low cost, and ability to produce large-scale models without support structures. It’s typically used for aesthetic models, packaging prototypes, or architectural mock-ups where mechanical performance is less critical but visual form matters.

11. DED (Directed Energy Deposition)

Directed Energy Deposition (DED) is an advanced 3D printing type primarily used for metal and alloy components, especially in repair, refurbishment, and large-format industrial applications. It works by feeding metal wire or powder through a nozzle while simultaneously melting it with a focused energy source – a laser, electron beam, or plasma arc. The molten material is deposited onto a substrate, where it solidifies to form the desired geometry, layer by layer.

What makes DED unique is its ability to add material to existing parts or build entirely new structures onto complex surfaces, even in multi-axis configurations. It’s widely used in aerospace, energy, and defense sectors for repairing high-value components like turbine blades, mold tools, and structural parts, where precision and material integrity are essential.

12. Binder Jetting

Binder Jetting is a versatile 3D printing type that uses a liquid binding agent to selectively fuse layers of powder, such as metal, sand, or ceramic, rather than melting the material with heat. A print head moves across a bed of powder, depositing tiny droplets of binder where needed, while a roller spreads a fresh layer of powder after each pass. The final part, often called a “green part,” is then cured and typically requires sintering or infiltration to achieve full strength.

Binder Jetting has the ability to produce parts at high speed and with excellent scalability, especially for complex geometries and large batch production. It’s commonly used in applications such as lightweight metal components, industrial tooling, and full-color models for design visualization, making it one of the most flexible non-thermal 3D printing types available today.

Image: Xmake Metal 3D Printing Parts

Materials Used in 3D Printing

The performance and cost of a 3D printed part often depend more on the material than the machine itself. From plastic filaments to metal powders, photopolymers, and composite blends, the range of materials used in 3D printing has expanded rapidly to meet the needs of different industries and applications.

- Plastic 3D printing is the most widespread, using materials like PLA, ABS, PETG, and nylon. These thermoplastics are common in FDM and SLS printing and offer a good balance of strength, flexibility, and cost for rapid prototyping and light-duty parts.

- Resins, used primarily in SLA and PolyJet printing, offer high resolution and smooth surface finishes, ideal for applications like dental models, jewelry prototypes, and visual mock-ups.

- Metal 3D printing uses materials such as stainless steel, titanium, aluminum, and Inconel in powder form, such as DMLS, SLM, or EBM processes. These parts are known for their strength, thermal resistance, and durability, often rivaling forged or machined components.

- Composites and hybrid materials, including carbon fiber-infused polymers or ceramic-filled resins, combine the benefits of multiple materials and are increasingly used for lightweight structural parts and high-performance applications.

Each material type comes with its own trade-offs in terms of cost, strength, printability, and surface quality. Understanding these differences is key to selecting the right combination of printing process and material for your specific application.

How to Choose the Right 3D Printing Type?

With so many types of 3D printing available, selecting the right one depends on your project’s specific requirements—there’s no one-size-fits-all solution. The best choice comes down to balancing material properties, accuracy, cost, and intended use.

Here are the key factors to consider:

- Material: Not all technologies support the same materials.

The type of 3D printing you choose must align with your required material, since not all technologies support the same range of materials.

- Part Function: Choose based on how the part will be used.

If your part needs to withstand mechanical stress, thermal loads, or daily use, you’ll need a 3D printing type that produces strong, functional components rather than just visual models or prototypes.

- Surface Quality: Some types offer finer resolution and smoother finishes.

When dimensional accuracy, fine details, or a smooth surface finish are essential, some printing types are far more capable than others at meeting those aesthetic and tolerance-driven demands.

- 3D Printing Cost: Budget and production volume will influence your choice.

Depending on your budget and production goals, certain 3D printing types are better suited for affordable prototyping or large-batch manufacturing, while others may involve higher upfront costs but deliver superior quality or throughput.

- Part Size: Consider build volume and support requirements.

The size of your part and the complexity of its geometry, especially internal channels, overhangs, or lattice structures, will influence whether you need a process that requires support structures, offers large build volumes, or can print unsupported designs reliably.

By weighing these factors, you can narrow down the right 3D printing type that meets both your technical goals and business constraints.

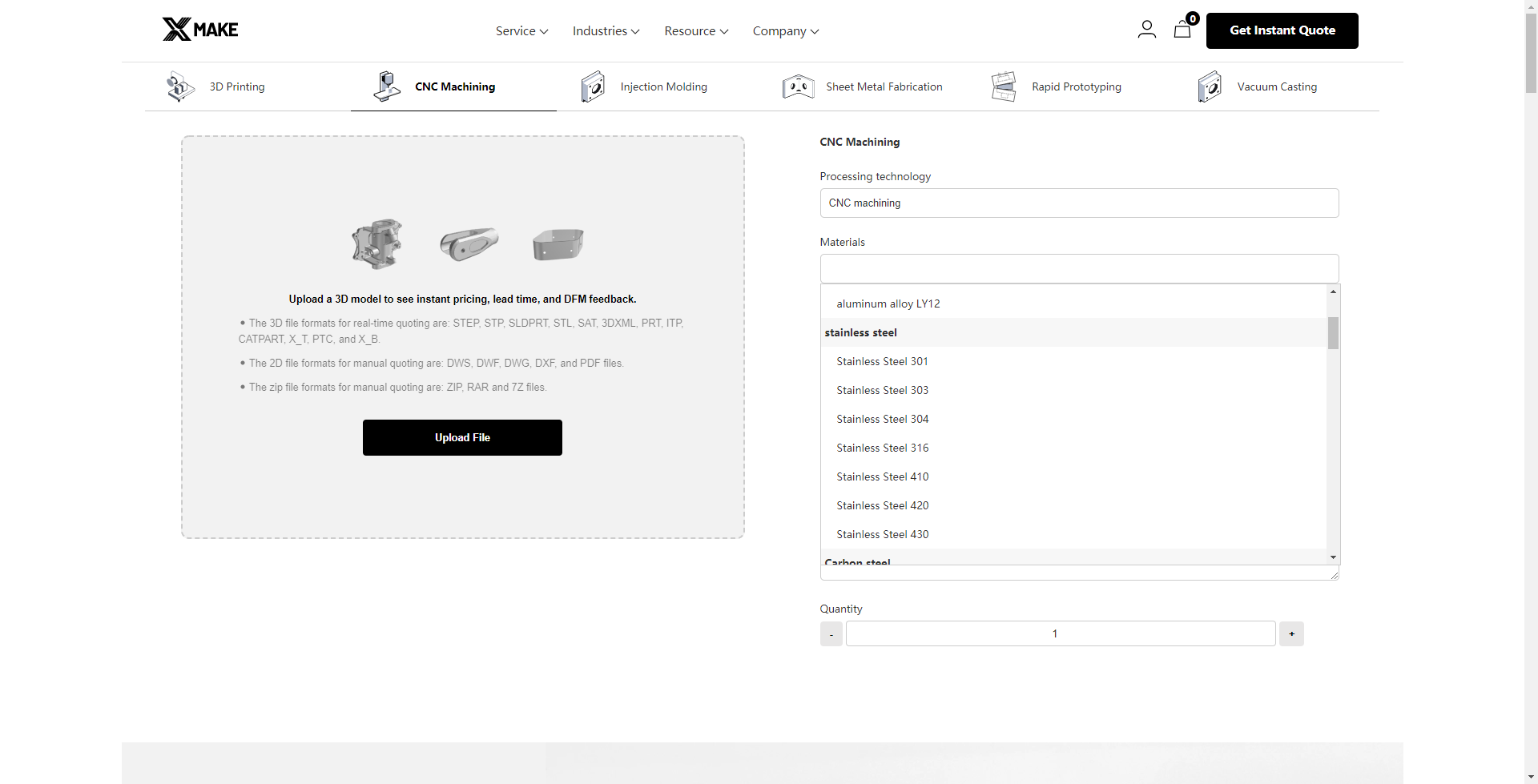

Get Professional 3D Printing Services

Not every project is suited for desktop printing or trial-and-error. A 3D printing service gives you access to industrial-grade machines, certified materials, and expert support. Professional providers can help you meet technical and production goals. With online quoting and global fulfillment, today’s 3D printing services are fast, scalable, and built for business.

FAQs

1. What are the three main parts of the 3D printing process?

The 3D printing process generally involves three main stages: product design, printing, and post-processing. It starts with creating a digital 3D model using CAD software. Next, the file is prepared and sent to the printer, where material is deposited layer by layer to form the object. Finally, post-processing steps, such as cleaning, curing, or surface finishing, are applied to enhance the part’s appearance or performance.

2. What is the best type of 3D printing?

There’s no single best type; each has its strength. FDM is ideal for simple, affordable, sturdy parts. SLA offers fine detail with layer resolutions around 25–100 microns (0.025–0.1 mm), making it perfect for intricate models; and metal printing like SLM or DMLS is ideal for functional, high-strength components.

3. Which is better, FDM or SLA?

When discussing SLA vs FDM, FDM 3d printer is popular for its affordability, ease of use, and strong, functional parts, making it ideal for prototypes and simple end-use items. SLA 3d printer, however, excels in producing high-resolution models with smooth surfaces and fine details.