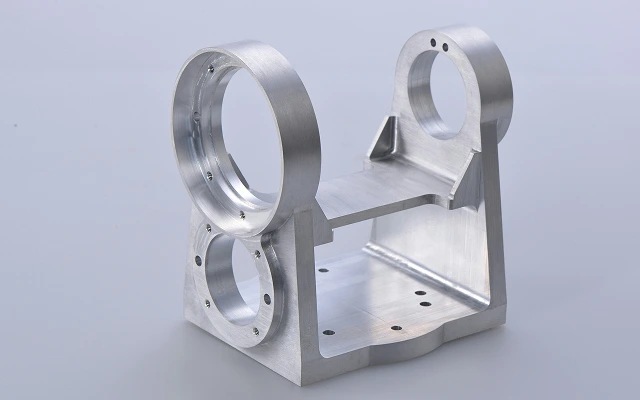

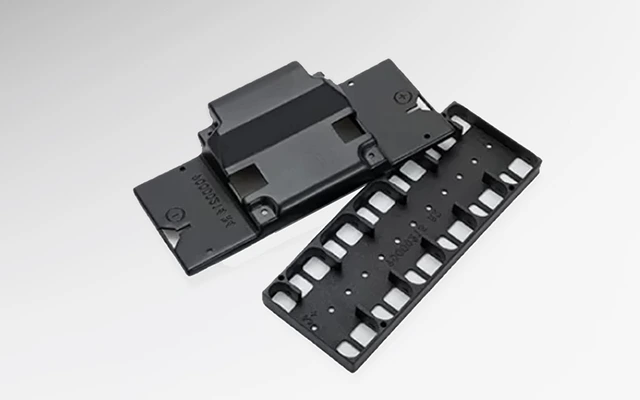

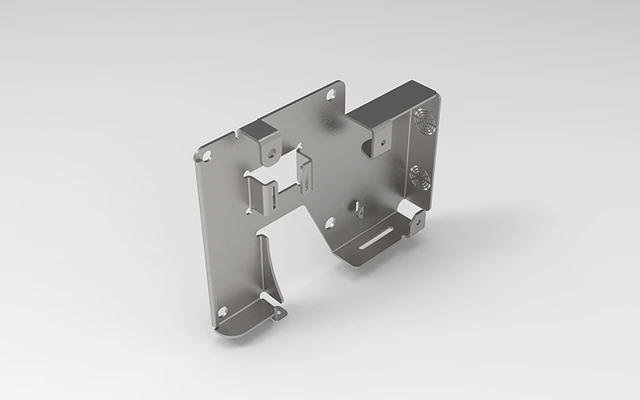

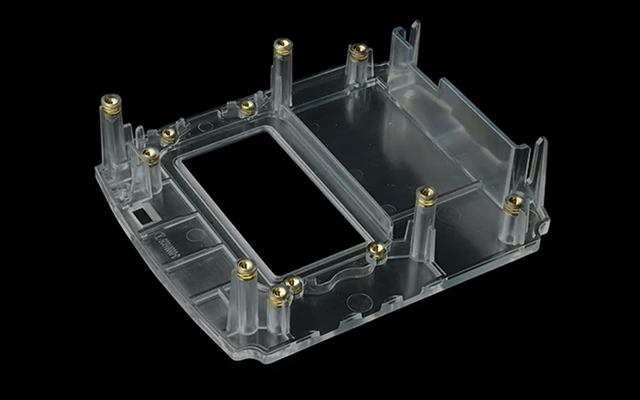

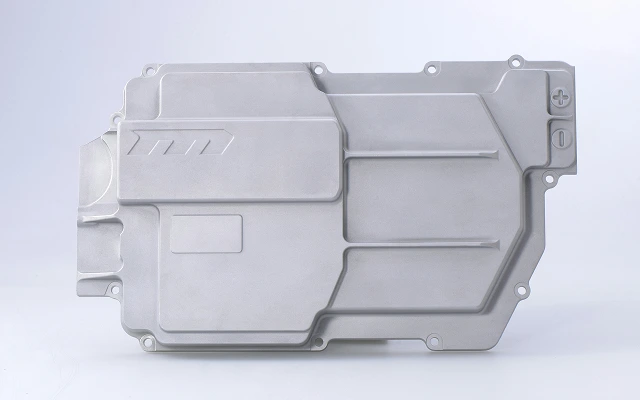

automotive parts manufacturing solutions, customize your auto parts

Professional automotive parts manufacturing factory. Capable of producing high-quality auto parts that meet industry standards. In the past ten years, we have provided key parts for dozens of car companies and dozens of car models without any problems. At the same time, we are constantly improving the production process and production costs of auto parts, so that you can realize your automotive project at a low cost.