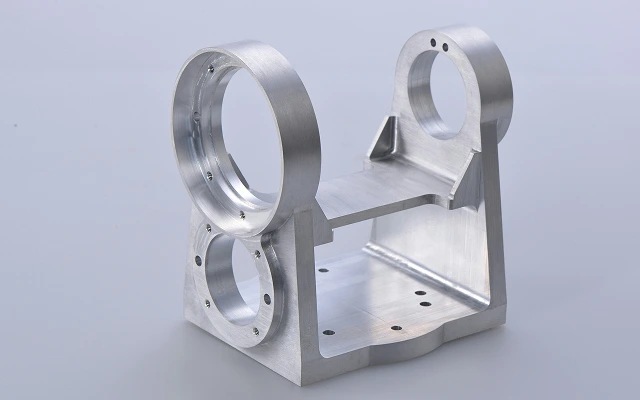

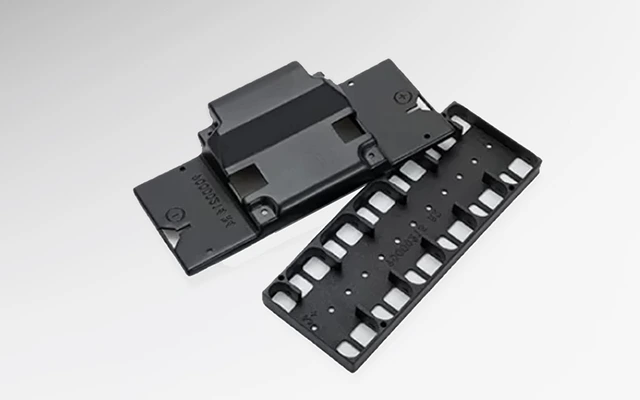

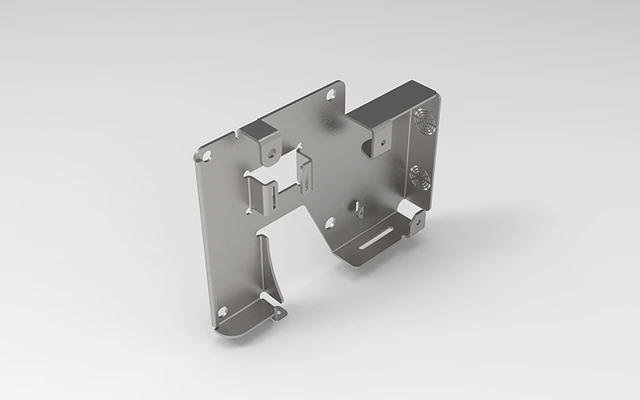

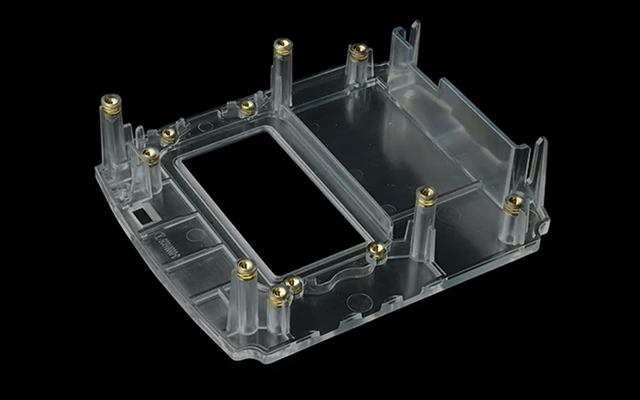

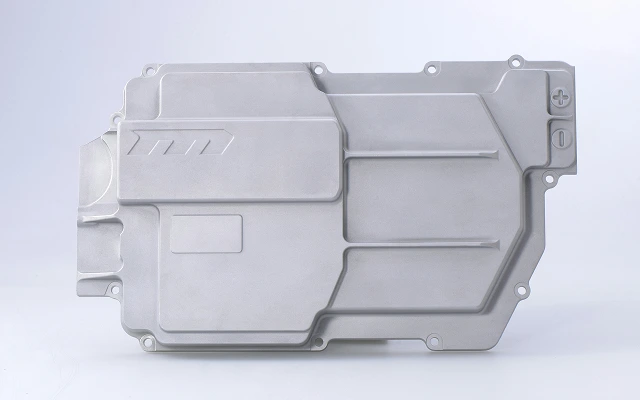

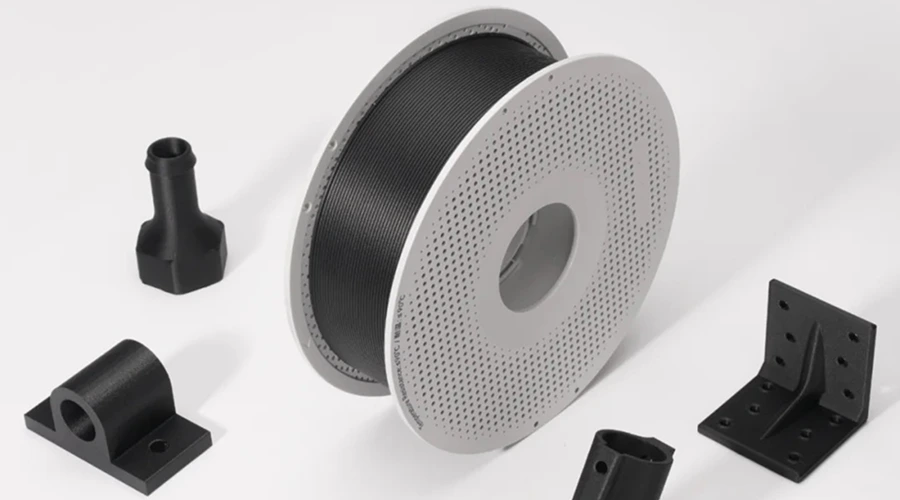

Aerospace Parts Manufacturing solutions, customize your parts

ISO-9001 certified aerospace CNC machining and 3D printing services. We produce mission-critical components for satellites, drones, and aircraft with NASA-grade precision and accuracy. 40% faster lead times than industry standards. Zero defect record across 200+ aerospace projects.