![3D Printing Cost: A Complete Guide! [2025] 3D Printing Cost: A Complete Guide! [2025]](/Extres/Img/wp-content/uploads/2025/06/xmake.com_.png)

With the rapid growth of additive manufacturing, 3D printing has become more accessible than ever, both for hobbyists and businesses alike. But whether you’re exploring it as a creative outlet or considering it for commercial use, one critical question often arises:

- How much does 3D printing really cost? – From buying your first machine or outsourcing a professional 3D printing service, the financial implications can vary widely.

Let’s explore more:

- Is it cheaper to print at home or rely on a professional service?

- Are the upfront costs worth the long-term benefits?

This guide will break down every component of 3D printing expenses, including machine investments, material choices, labor, and hidden operational fees. By the end, you’ll have a clear framework for estimating your 3D printing cost.

Image: Xmake Part 1 – 3D Printing

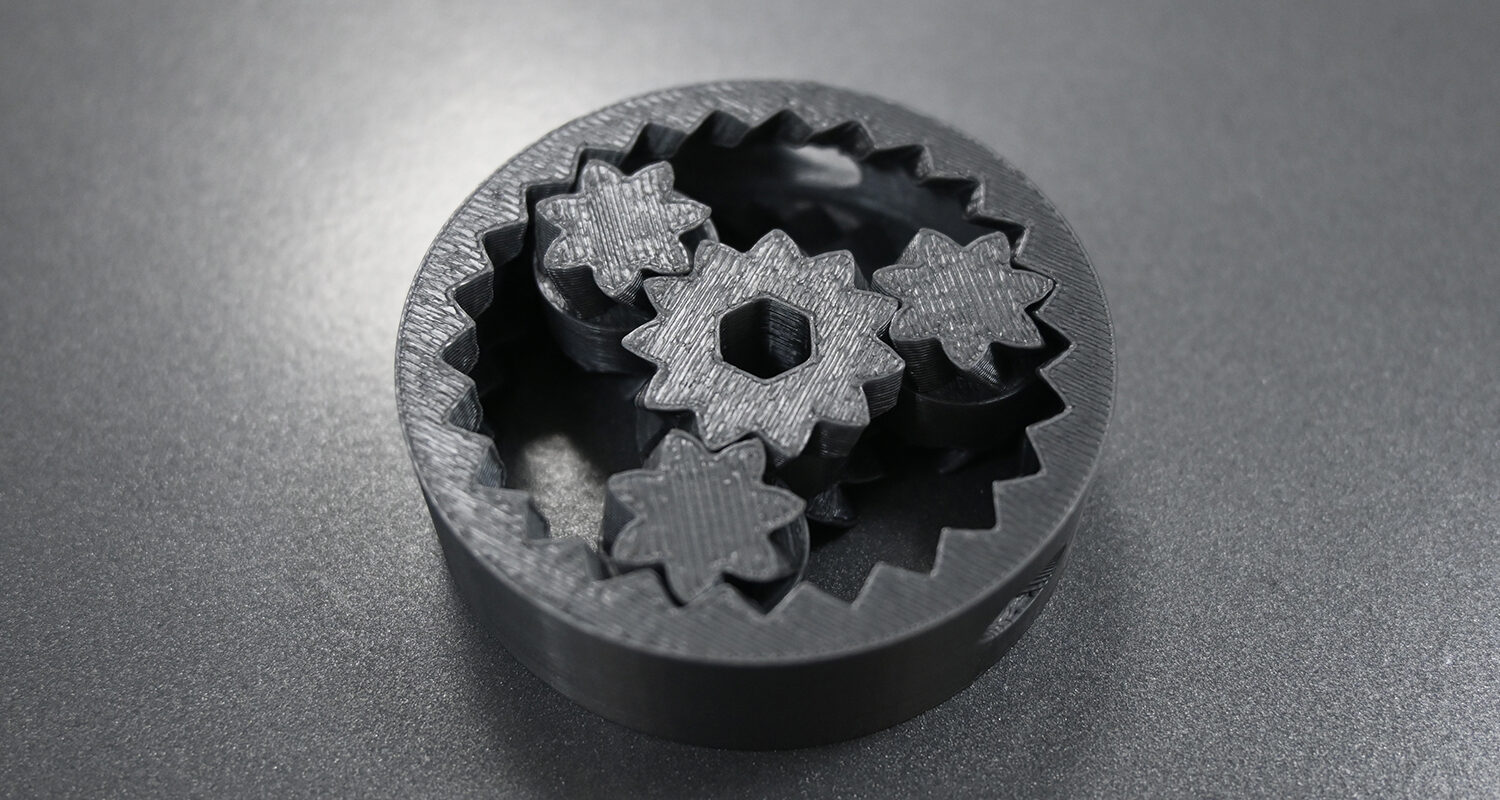

How Does 3D Printing Technology Affect Cost?

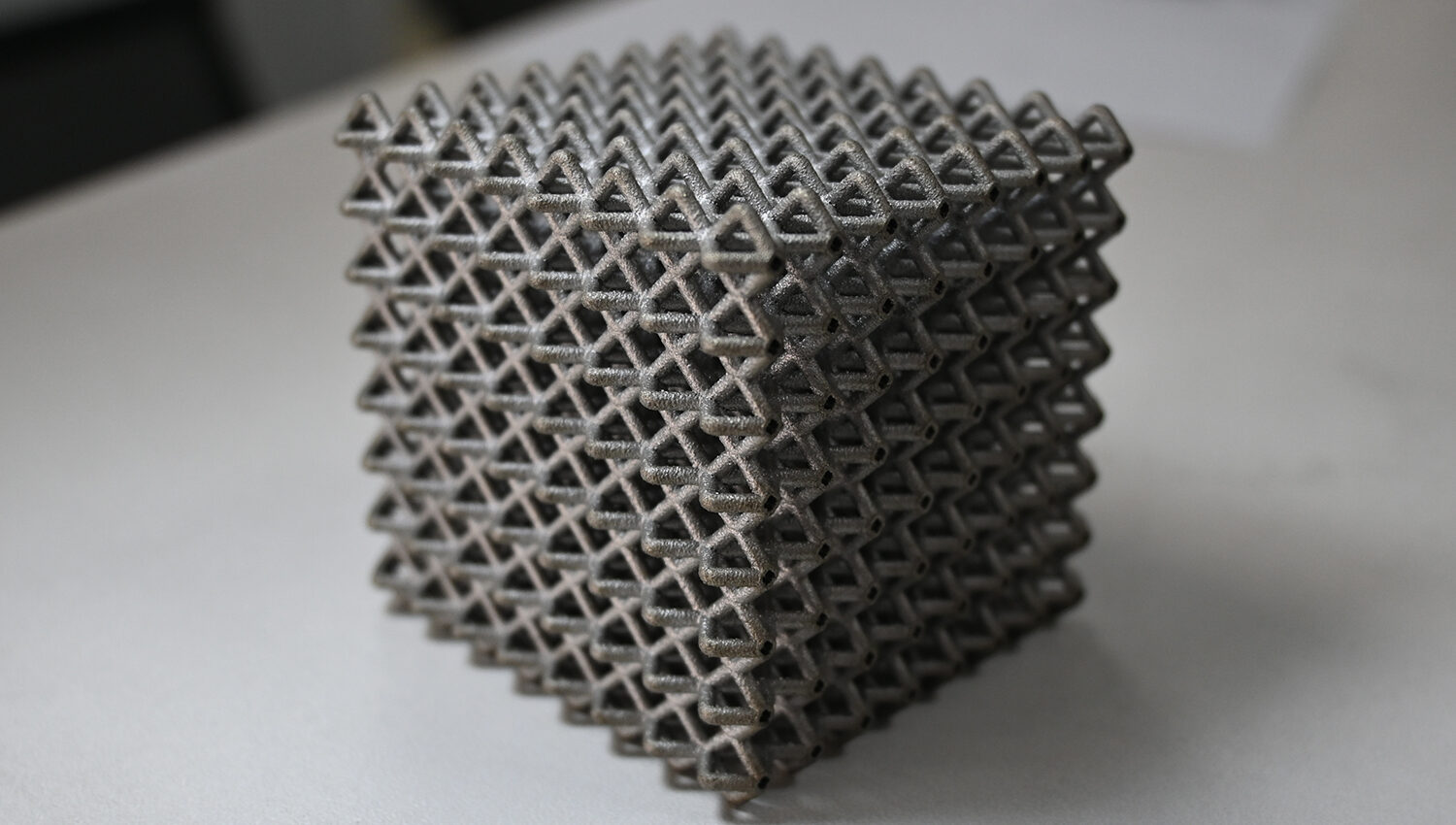

Different 3D printing technologies affect cost by varying in material efficiency, machine throughput, equipment price, and post-processing complexity, ultimately shaping the total cost per part and the economic viability of specific applications.

For businesses entering or expanding into additive manufacturing, investing in 3D printing technology is a strategic decision, not just a purchase. The cost of acquiring 3D printing infrastructure can vary significantly depending on:

✅The scale of production – Larger production volumes typically lower the per-unit cost, but initial setup costs increase with scale.

✅The complexity of parts – More intricate designs require longer print times and may need specialized equipment, increasing cost.

✅The materials required – High-performance or specialty materials often have higher prices, directly impacting overall printing expenses.

Entry-level industrial printers may start around $5,000, while high-performance systems capable of large-batch or multi-material printing can exceed $250,000. It’s also important to consider auxiliary costs like:

- Slicing software

- Maintenance contracts

- Post-processing equipment

- Operator training

Choosing the right 3D printing technology – FDM, SLA, SLS, or MJF, etc – depends on your production goals, part performance needs, and turnaround time.

For example, companies needing strong, functional prototypes may prioritize SLS or MJF systems, while those producing detailed visual models might favor SLA.

Beyond machine specifications, facility setup plays a role in capital investment: ventilation, power supply, and environmental controls may be necessary for smooth and safe operations.

While the upfront costs may seem high, a well-aligned 3D printing setup can reduce lead times, lower tooling expenses, and open doors to new service offerings, making it a powerful long-term asset for many operations.

Image: Xmake Part 2 – 3D Printing

Material Costs for 3D Printing

Material selection plays a significant role in determining the overall cost of a 3D printing project. The type of filament or resin used not only affects pricing but also impacts the mechanical properties, finish quality, and application suitability of the printed parts.

Common Filaments and Resins

Different materials come with different price points, depending on their performance, brand, and availability. For example, PLA is typically affordable and beginner-friendly, while materials like Nylon or Carbon Fiber composites are designed for professional or engineering-grade applications and cost considerably more.

Let’s check a table about common 3D printing materials costs that meet the market standard based on Amazon:

| Material Type | Application Scope | Average Price (USD/kg or L) | Notes |

| PLA (Polylactic Acid) | Prototyping, hobbyist models | $15–$25 per kg | Easy to print, biodegradable |

| ABS (Acrylonitrile Butadiene Styrene) | Functional parts, automotive | $15–$30 per kg | Heat-resistant, needs ventilation |

| PETG | Durable consumer products | $15–$35 per kg | Strong, good chemical resistance |

| TPU (Thermoplastic Polyurethane) | Flexible parts, wearables | $25–$60 per kg | Flexible, rubber-like material |

| Nylon | Mechanical parts, tooling | $35–$80 per kg | Strong, moisture-sensitive |

| Standard Resin (SLA) | High-detail prototypes | $35–$70 per liter | Brittle but excellent surface detail |

Estimating Material Usage

To estimate how much material a print will consume, it’s essential to use slicer software (such as Cura, PrusaSlicer, or Simplify3D), which provides precise weight and length estimates based on your 3D model. Key factors like infill density, wall thickness, and support structures can significantly influence material consumption and, thus, cost.

| Factor | Description | Impact on Material Usage |

| Infill Density (%) | Percentage of internal structure filled | Higher density = more material |

| Wall/Shell Thickness | Thickness of outer walls of the print | Thicker walls = higher usage |

| Support Structures | Temporary supports for overhanging features | Increases material waste |

| Model Size & Geometry | Overall size and complexity of the object | Larger/complex = more filament |

| Layer Height | Thickness of each printed layer | Lower height = more layers = more material |

Operational Costs for 3D Printing

Beyond the initial capital and material investments, operational costs represent a critical component of total 3D printing expenses, particularly for businesses seeking consistent throughput and reliability. These costs encompass electricity consumption, equipment wear and maintenance, routine calibration, and the replacement of consumables such as nozzles, build surfaces, and filters.

Power usage can vary depending on printer size and technology—desktop FDM machines typically consume 50–150 watts per hour, while industrial systems may require significantly more energy.

Moreover, ongoing maintenance is essential to sustain print quality and reduce downtime, with costs scaling depending on usage frequency and part complexity. Factoring in these operational variables ensures a more accurate and realistic evaluation of total production cost per part, supporting better financial planning and equipment utilization in a business context.

Labor and Time Cost for 3D Printing

Labor and time are often underestimated factors that significantly influence the true cost of 3D printing, particularly in business environments where efficiency and productivity are key.

While the printing process itself may be automated, considerable human input is required before and after each print, ranging from model preparation and slicing to printer setup, monitoring, post-processing, and quality inspection.

These tasks consume valuable employee hours, and when translated into labor costs, they can substantially increase the total cost per part. Moreover, longer print times not only tie up equipment but also delay project timelines, affecting delivery schedules and operational throughput.

Depreciation and Equipment Cost for 3D Printing

Depreciation and equipment-related costs are essential considerations for accurately calculating the long-term financial impact of 3D printing operations. Unlike consumables, 3D printers and auxiliary hardware (e.g., post-processing stations, curing chambers, air filtration systems) represent capital assets that lose value over time through regular use, wear, and technological obsolescence.

Businesses must account for this decline in value, typically over a 3- to 5-year depreciation schedule, when assessing the cost per printed part. Additionally, the total cost of ownership includes ongoing expenditures for repairs, software licenses, firmware updates, and potential downtime due to hardware failures.

Other Costs for 3D Printing

In addition to material, operational, and equipment-related expenses, other indirect costs can influence the total cost of 3D printing. These may include shipping and logistics for outsourcing services, intellectual property licensing, or the expense of failed prints due to human or technical error.

While often overlooked, these secondary factors can accumulate over time and should be included in cost estimates to ensure full pricing transparency and profitability.

Image: Xmake Part 3 – 3D Printing

3D Printing Cost Calculators

To improve accuracy and transparency in cost estimation, various 3D printing cost calculators are available to help businesses and hobbyists assess the full expense of each print job.

These tools consider multiple cost factors, such as material consumption, print time, electricity usage, and overhead, providing detailed breakdowns that support pricing decisions and project budgeting.

PrusaPrinters Cost Calculator

This calculator, provided by Prusa3D, is specifically designed for users of Prusa printers but is flexible enough for general use. It allows inputs for filament type, print time, electricity cost, and printer depreciation, offering a detailed cost-per-print estimate. Its integration into the PrusaSlicer environment also makes it convenient for daily professional workflows.

Omni Calculator – 3D Printing Cost

The Omni Calculator is a general-purpose tool that supports a wide variety of inputs, including material cost, print speed, energy consumption, labor cost, and markup rate. It’s highly intuitive and suitable for both individuals and service providers who want a straightforward breakdown of production expenses. The interface is web-based and accessible without registration.

Visit Omni Calculator

3D With Us – 3D Print Cost Calculator

3D With Us offers a user-friendly calculator tailored for makers, freelancers, and small businesses offering 3D printing services. It allows users to input model volume, filament type, electricity rate, machine cost, and profit margin. The calculator also provides a preview of how changes in each input affect the final pricing, making it especially useful for quote preparation and client communication.

Visit 3DWithUs Cost Calculator

How to Find a 3D Printing Service?

Finding a reliable 3D printing service requires evaluating several key factors, including production capabilities, material options, pricing transparency, and delivery timelines.

Start by identifying service providers that align with your technical needs, such as prototyping, low-volume production, mass production, or engineering-grade components, and review customer feedback, portfolio quality, and support responsiveness.

Online platforms, manufacturing networks, and specialized bureaus offer varying levels of customization and scalability depending on your project scope.

At Xmake, we provide a professional and highly efficient 3D printing service tailored for businesses seeking quality, consistency, and speed. Our platform supports a wide range of materials and additive manufacturing technologies, making it ideal for both functional prototyping and end-use part production.

Key features of Xmake 3D Printing Service:

✅Reliable: Strict quality control and industrial-grade machines ensure consistent, dependable results.

✅Versatile: Support for SLA, SLS, SLM, MJF, FDM, and DMLS with materials from basic PLA to high-performance resins and metals.

✅Responsive: Fast quoting, expert support, and real-time tracking throughout the order process.

✅Scalable: Suitable for both rapid prototyping and mass production runs across global markets.

Conclusion

3D printing cost is influenced by a variety of factors, from material choice and technology to labor, maintenance, and equipment investment. By understanding these elements and using the right tools or services, businesses can make smarter, more cost-effective decisions in additive manufacturing.

FAQs about 3D Printing Cost

1. How much does it cost to do 3D printing?

The cost of 3D printing can range from a few dollars to several hundred dollars per part, depending on material, size, complexity, and technology used.

2. How expensive is 3D printing filament?

Standard filaments like PLA and ABS usually cost between $20 and $50 per kilogram, while specialty materials such as carbon fiber, TPU, or engineering-grade nylons can exceed $60–$100 per kilogram.

3. Is it possible to 3D print a key?

Yes, a key can be 3D printed using a digital model and a rigid material, but its accuracy and durability depend on printer resolution and the strength of the chosen filament or resin.

4. Why is 3D printing so expensive?

3D printing can be expensive due to the cumulative impact of machine depreciation, material costs, labor time, energy consumption, and necessary post-processing for functional or aesthetic finishes.

5. Is it free to 3D print?

While the design files may be free or open-source, 3D printing always incurs costs for materials, equipment usage, maintenance, and power, making it far from a no-cost process.